Reader storage solutions ranged from using homemade dollies, cinder blocks, X-shaped support structures, saw horses, Torklift Wobble-Stoppers, and Rieco-Titan Camper Dollies. Many readers just put their camper low to the ground, with no underbelly support. Others keep their camper on truck with the jacks up and/or down.

The oldest camper from our question this week was Mark Arnold’s 1976 Dreamer. That’s 351 years old in truck camper years. How does Mark Arnold store his truck? Well, he uses it year-round, so he hardly stores it at all!

Here are the reader ideas on how to store and support a truck camper:

“We take the camper off the truck and rest it on a dolly so we can move it around the garage.” – Dave Barker, 2014 Ram 3500, 2015 Northstar 850sc

“We unload the camper and place cinder blocks for extra support at the four corners.” – Barry and Carol Schoenwetter, 2006 GMC Sierra 2500HD, 2005 Lance 1030

“We leave our camper unloaded without support.” – John and Cathy Strasser, 2012 Chevy 2500, 2013 Eagle Cap 850

“I unload my camper without underbelly support.” – Mark Larson, 2014 Ram 3500, 2013 Lance 865

“I remove my camper from the truck and use an underbelly support along with the jacks. I put the jacks on blocks with just enough weight so that when I kick the blocks they don’t budge.

The under belly support is a two piece X-shaped assembly made of 3/4″ plywood reinforced with 2×3 along the edges. The two pieces are slotted where they cross so I can disassemble them.” – Dennis Volz, 2005 Ford F-350, 2006 Lance 845

“Unless I need the truck in the summer, the camper remains on with the jacks down. It can be removed temporarily for truck use. For the winter, non-campng season, the camper is off the truck with support beams under the front of the belly to help stabilize the front jacks. The jacks are as low as possible.” – Richard Johnson, 2004 Ford F350, 2007 Lance 1181

“I’m in a HOA area, but with the camper unloaded I can store it in the backyard. So the camper is off loaded onto stands. They are set to the jacks being within one-inch of being fully retracted.” – Leonard Pennock, 2006 Dodge Ram 3500, 2003 Eagle Cap 950

“I unload the camper with under belly support. I use a four wheel farm trailer for the base with the camper jacks down for additional stability, but no load on them.” – Jim Frensko, 2001 Ford F250, 2003 Sun Lite

“I took the box off of an old grain wagon and shortened the running gear (frame) and welded square tubing between the axles of the wagon. Now, I just steer the wagon under my camper, set the camper on the wagon, and raise the jacks a couple inches off the ground. When I want to use the camper, I raise the camper a couple inches, pull out the converted wagon, and back my truck under.” – Stu Dekkenga, 2008 Chevy 2500, 2011 Northstar TC650

More TCM Reader Recommended Products:

The 50 Best Flashlights and Lanterns | The Best Maps, Apps, and GPS Devices | The Best Portable Air Compressors | The Best Portable Grills

“We are fortunate to be able to store our Lance inside a pole barn when it’s not in use. Since it is not subject to weather or winds, we store in on the jacks just low enough so that we can walk under the cabover without hitting our heads. We have never had a problem storing it this way. Years ago when we stored another truck camper outdoors, we would place a railroad tie on two cement blocks set upright at both ends of the bed body and lower the camper onto the ties. We would leave just enough tension on the jacks to provide stability. This was when truck campers had only three jacks. We never had a problem with that either.” – Shelley Pike, 2009 Ford F350, 2006 Lance Sportster

“We support our camper with a rolling dolly that’s home made.” – Ronald Trotter, 2001 Dodge Ram 2500, 1996 Lance Squire

“My camper sits on wooden saw horses that I built. They go all the way across each end to hold it level. I keep the jacks down to keep it firm (without wobble) in our driveway. I tried store bought, steel saw horses that were supposed to hold over 3,000 pounds each, but those lasted only one time and broke down. So I built wood saw horses and all is good.” – Ed Henry, 2014 Ram 2500, 2014 Northstar 850sc

“I use four empty pool chemical pails (two are five-gallons, two are seven to eight gallons) to supplement the jacks when the camper is dismounted. I gradually lower the unit onto the pails until the jacks lift free and realign themselves. Then, I run them down again just enough to take up some of the weight.

Thus, I have an eight-point support, half jacks and half underbelly. With this low stance and a camo cover, the rig is nearly invisible from the road. On those occasions when I drop the camper at a site, I use a pair of forty-gallon recycling cans. I put the turnbuckles in the cans for aesthetics and security.” – Mike Daily, 2010 GMC 2500, Palomino Bronco

“I unload the camper and have underbelly support. The saw horses are two foot in height 2×6 construction, so it’s low to the ground. As this is an older camper the cabover does not fit on the Tacoma without a 2×4 base to raise it from hitting roof. The 2×4 base also has a plywood top. I remove the base and support it with the saw horses and lower camper on to it. It is lower to the ground as we live in an area that gets high winds. Having the camper higher on standard saw horses without support is not an option.” – Larry Martin, 2010 Tacoma, 1985 Travelmate

“When we’re out camping, we drop the jacks for added stability inside. If we need the truck during camping season, the camper is placed on two homemade metal saw horses with the jacks down.

In the winter, we leave the camper in the truck bed, but use the jacks to take most of the weight off the truck. If your camper is 99 years old, then mine is over 300 “camper years” old.” – Melissa Malejko, 2002 Chevy Silverado 2500 HD, 1981 Okanagan

“My camper is stored off the truck, lowered, not supported, in a nice warm or air-conditioned shop. We have stored all of our campers in this same manner.” – Bob Nelson, 2015 GMC Sierra 3500, 2013 Arctic Fox 1140

“My camper is unloaded, without underbelly support.” – Pat Bullock, 2002 Chevrolet 2500, 2000 Lance 1030

“I rarely leave it on the truck without legs down. That is only a temporary or overnight. Longer than that, I put the legs down and I lift the camper enough to take the weight off the truck and level the truck camper.

I never use underbelly support. The underbelly structure is not visible, so I have no idea of the design’s strong and weak points. The truck camper I own was designed to be supported on the legs and that is how I do it. Supporting the truck camper on its underbelly and not doing so in a completely flat and full contact surface such as the bed of the truck invites more issues than needed.” – Don Pryor, 2015 Ford F350, 2008 Arctic Fox 1150

“In eleven months we have only taken the camper off once, mainly because I move so often. I plan to put it on stands more often once I become more proficient at backing the truck under it without a spotter.” – Pat Corrill, 2015 Ford F350, 2015 Hallmark Ute

“I unload the camper without underbelly support.” – Tom Adams, 2001 GMC Sierra 2500HD, 1998 Northland 10’

“We have one of the heavier truck campers and are always concerned about the strength of the legs. When camped for a day or two we leave the camper on the truck with the legs down for extra stability.

If we are longer in one place we will take the camper off the truck, but like to support it. We have never had a problem, but don’t want to either. We carry two six ton screw jacks from Camping World and a 2×4. The camper is lowered until the sewer connection is close to the ground and then the front of the camper rests on the jacks and the 2×4. The rear of the camper doesn’t get anything extra.

In the winter, the camper comes off the truck, is covered and then has four six-ton jacks and 2x4s for support. We now carry the two jacks in a milk crate in exterior storage, but used to put them in the wheel well area per tip from Rob McCullock. The extra small weight from carrying the jacks is worth our piece of mind.” – Anne and Joe Brown, 2013 Ford F450 , 2013 Chalet TS-116

“Ninety percent of the time the camper is on the truck, jacks off, ready to camp. I have to put the jacks on when I take the camper off. If it’s only for a day or two, I leave it up on the jacks so I do not need to lower and lift it again. If it’s off longer I have a dolly I made for the camper.” – Bill Harr, 2005 Tundra, 2013 Hawk shell custom build

“I rent indoor storage for my boat, camper, and an older 1973 pickup in the winter. The old pickup is strong enough to hold the camper, and by itself is useless. It’s a 1973 GM Camper Special, two wheel drive, 454 V8 in Minnesota winter ice and snow. The current camper is stored in that pickup’s box.” – Philip Tron, 2009 Chevy 3500, 2012 Lance 1050

“I believe having it supported while in storage is huge. I don’t leave it on the truck unless we are traveling. At home it goes on a dolly so that I can push it around in the barn. I also lower the jacks just until they are snug for a bit of extra support.” – Gerry Minor, 2009 Ford F150, 2006 Palomino 1251

“I leave the camper on the jacks and lower it as far as I safely can. This allows me to raise the front slightly to improve water drainage from the roof. It is very stable and easy to enter and exit the camper in this position.” – Eldon Rhodes, 2008 Chevy 3500HD, 2011 Lance 1050

“I unload my camper with an underbelly support.” – Andre Van De Walle, 1997 Dodge Ram, 2012 Travel Lite 1000RX

“I unload the camper without underbody support.” – Bill Gage, 2003 Ram 2500, Northstar TC650

“This is a good question as I am coming up to the first winter with my camper. It is still on the truck, with one more camping trip planned. I think I am going to have it sit on blocks under the camper with the jacks down as well. But from what I hear, it’s not really required and jacks only will work.” – Dwight Donaldson, 2014 2500 HD, 2015 Wolf Creek 840

“We take it off the truck and rest the camper on saw horses with the four corner legs bearing some of the weight. We go in and out of it periodically and resting on two saw horses provides some degree of stability.” – Kurt Haskel, 2002 Ford F350, 2011 Wolf Creek 850

“I empty the tanks, remove clothes, and food. Then, I remove the camper from the truck and place saw horses with 2×6 boards. Then, I connect the Torklift Wobble Stopper and store it in the garage.” – Marc Quintana, 2007 Chevy 3500HD, 2014 Wolf Creek 850

“I unload the camper with electric jacks and store it without underbelly support.” – Lance Martin, 2015 Ford F250, 2014 Palomino HS-6601

“I unload my camper without underbelly support. I lower the corner jacks almost all of the way down. That’s how it was stored at the dealer. Looking under the camper, it looks as though the support under the floor is strong enough to do it this way.” – Howard Bisco, 2015 Ford F250, 2014 Palomino HS6601

“I never remove camper from the truck. The camper is light weight. I do not use the jacks installed.” – Chris Walton, 2008 Nissan Frontier, 2008 Four Wheel Camper Eagle

“I unload my camper, put it on a dolly, and roll it into the shop where it is stored.” – Paul Oulton, 2014 Ford 350, 2015 Northstar 850 popup

“The camper is stored in my garage. If I have to work on the camper, it’s stored on a dolly that I purchased from Lance. Otherwise it’s stored on the truck.” – Carl Mutschler, 1995 Dodge 3500, 1995 Lance 1181 Max

“My camper is unloaded without underbelly support.” – Mike Borrego, 2005 Dodge 3500, 2008 Host Yellowstone

“We unload the camper and lower it as close to the ground as possible. We put stacker jacks at the front corners with a 2×4 on edge across the bottom. We do that again for the rear. The 2x4s have small holes drilled so the stacker jack head sits inside the hole. We bring the stacker jacks up to the camper bottom. It offers support, removes jiggle, but isn’t holding much weight. We use the same system when camping.” – Diane Larsen, 2012 Ford F350, 2007 S&S Montana Ponderosa 8.5 FBSC

“When the camper is unattached, it is on jacks and on cinder blocks. I am afraid of high winds and I like to go in/out without any fear of hurting the floor. I the leave power attached and it’s under shelter.” – Larry Espey, 2000 Toyota Tacoma, 2000 Sun Lite

“When the camper is off the vehicle I place concrete blocks under the corners and a couple down the center. The only time the camper is off is when I need the truck to haul something or to work on the unreachable parts of the camper. My previous Four Wheel camper was stored on a concrete pad, but that was not good for the bottom side of the camper. Having the camper up eight inches on the blocks provides good air flow and does not allow the bottom to sit in moisture, debris, or critters.” – Ralph Bunn, 2015 GMC 2500HD, 2004 Four Wheel

“Our camper jacks were removed when we permanently mounted the camper to the utility bed. It’s always ready to go!” – Cliff and Susie Kellogg, 2006 Chevy 2500 HD, 1999 Apache popup

“We leave our camper on the truck without the jacks down. We have a large metal building. Our rig is parked in there with the popup top up and the camper plugged in to shore power.” – Mike Cash, 2014 Ram 2500, Hallmark K2

“My camper is stored off the truck inside a building. It sits on 4×8 sheets of plywood supported by four sawhorses. The plywood is used in the truck bed to raise the camper enough to properly clear the roof of the truck cab. The jacks are down and it’s lightly loaded.” – Bill Jones, 2003 Ford F350, 1997 Bigfoot 10.6

“When the camper is in use or will be used in the near future (usually all summer and most of the fall), I leave it loaded on the truck with the jacks down.

When the camper will not be used for a couple of weeks or the truck is needed for other duties, I unload the camper with underbelly support.” – Jerry Smith, 2012 Chevrolet Silverado 3500, 2013 Arctic Fox 992

“I unload the K2 without underbelly support. It is kept inside the garage when I’m not camping.” – Chuck Pearson, 2008 Chevy Silverado, 2013 Hallmark K2

“I leave my camper loaded on the truck without the jacks down.” – Craig G. Howlett, 2005 Ford F350, 2011 Lance 1191

“I leave our camper on the jacks lowered. It is also in our RV garage all dry and safe. If we are parked for an extended period of time, I will lower the jacks to touch the ground for stabilization.” – Jim Furubotten, 2006 Ford F350, 2014 Northern Lite 10-2SE

“We leave the camper on the truck with the jacks up for most of the year. If we off-load it, we do not support it. In the winter, due to snow and heavy wind, we do use Torklift supports which are basically heavy duty saw horses. We have to take it off in the winter to plow, but we use it at least one week every month in New England and New York.” – Jim McCrea, 2013 Ford F350, 2013 Northern Lite 10-2 CD SE

“My unit is new, but I ordered metal saw horse brackets on line from McCoy tool company. Each bracket supports over 3,000 pounds. This big boy doesn’t budge.” – Glen Dougherty, 2015 Ford F350, 2016 Northern Lite 10-2

“At home while in my metal storage building, I use a Rieco-Titan’s eight foot camper dolly. Rieco-Titan was awesome to work with as the original wheels would not turn under the forward part of truck camper. My camper is 4,400 pounds dry. We found that a pair of off-set wheels did the trick. Kudos to Rieco-Titan.

I carry two 2″x6″x4′ boards and use four of the screw up Jack Stacks from Camping World under each corner. The boards go between the jacks and the camper on each end. In all cases loaded or unloaded I use the truck camper jacks to take some of the weight off the dolly or board/jacks and/or provide stability if the truck camper is being accessed.” – Ken Sanders, 2001 Ford F350, 2011 Host Everest

“I built a dolly out of 2×6 and six four-inch heavy duty casters. I sit saw horses on the dolly and lower the camper. This way I can move the camper in and out of storage. Using the sawhorses rather than sitting the camper on the dolly gives me extra storage under the camper.” – Larry Hoare, 1996 Dodge Ram 2500, 1991 Jayco

“I unload the camper without underbelly support. It is supported solely with Rieco-Titan electric jacks and the camper is fully lowered.” – John Doe, 2015 Chevrolet Silverado 3500HD, 2015 Arctic Fox 811

“I leave the camper on the truck with the jacks partially supporting the weight and cover my camper with a tarp. I cover the wheels for sun protection. I remove the snow when possible. That’s for winter only!” – Allan, 1995 Dodge Ram 2500, 2000 Lance 1150

“We store our camper at a storage facility. It’s under a canopy and not garaged. We unload the camper and use custom made heavy weight saw horses to carry some of the weight. The Happijacs take most of the load. Saw horses are there more for side-to-side stability rather than load-bearing. When at rest, the lower floor of the camper is about three feet off the ground.” – Dan Daddieco, 2015 Ram 3500, 2015 Eagle Cap 1165

“When we have the camper at home between trips, it stays on the back of the truck with the jacks up. Our driveway is not flat so we back the truck in so that the weight pushes toward the cab of the truck. Of course the refrigerator does not function while parked like this. We take the rig back to the curb the day before the trip to turn on the refrigerator. When we put Jason in storage, he is off the truck on his legs almost sitting on the ground. I tried the saw horse thing, but found it was quicker, easier, and just as effective to unload and lower almost to the ground. Some day I hope to have some land with a large shop building and a dolly to put Jason or his successor on.” – Pam Conner, 2015 Ford F350, 2015 Arctic Fox 1150

“I remove the camper from the truck if it won’t be used for an extended period of time. I stack two high cinder blocks on the left and right sides in the front middle and back. Then I put three treated 4X4s on top of the blocks to evenly distribute the load.

I then lower the jacks to just touch the ground for extra stability.” – Jeff Intemann, 2015 Ram 3500, 2015 Adventure 86FB

“I have a 4″x4″ between concrete cinder blocks. I do the same for the winter except it is stored under cover in a heated garage.” – Rob Arnott, 2014 GMC Sierra 3500HD, 2010 Northern Lite 10-2 QE

“When the camper is not in use it is off the truck with two sawhorses bracing the bottom. The jacks are down for stability and support.” – Joe Johnson, 2005 Chevy Silverado LS, 2014 Real Lite SSD-1608

“The camper is on stands, built for me by my son-in-law. They are made of steel welded in the shape of a saw horse. They support the front and rear of the camper. Since the stands are only about twenty-four inches tall, I set them on cement blocks, unload the camper on them, and then put down the jacks to stabilize it.” – Don Warren, 2008 Dodge Ram 1500, Northstar Pop up

“Easter to Christmas the camper is loaded on truck and ready to go! It has water, a charged battery, and essentials. For the extreme winter, it’s unloaded with its legs down, sitting on large pallets for full support, winterized, and covered. There is a small electric heater inside for any emergency visits or when the mood hits to hide out.” – Frank Santore, 2005 Dodge 3500, 1999 Lance 1010

“When not in use, we take the camper off the truck. I made two X stands from one sheet of 3/4” treated plywood. The plywood is cut into four pieces two feet wide. Each piece is notched half way across so they fit together in an X.

These pieces go on the ground and a second full sheet of 3/4” plywood goes on top to provide a very stable solid floor to set the camper on. Additionally, I adjust the jacks so there is a slight pressure on them. When I load the camper, I use the plywood sheet and the X brace pieces for a 1 1/2″ spacer in the truck bed.” – Randall Rice, 2012 GMC 3500HD, 2002 Bigfoot 2500 10.6C

“I unload the camper without underbelly support. I do lower it to just above ground height. This makes it easier to get in and out of to clean and also makes it more stable than on extended jacks.” – Bill Peters, 2013 Chevy Silverado, 2013 Four Wheel Camper Hawk

“My Bigfoot has spent winters unloaded without underbelly support and has had no issues. Last winter was the first winter with the new truck. I left it on the truck all winter. While it was in storage I had a wood block under the hitch to take the camper’s weight off of the suspension. It worked great.” – Dave Miller, 2015 Ford F350, 2003 Bigfoot 10.6E

“Normally I leave the camper loaded on the truck without the jacks down. When we do unload it, we do not block it or have underbelly support. We lower it to about 12” close to the ground.” – Robert Morrissey, 2011 Ford F350, 2012 Lance 850

“This will be my first season storing a camper and I am in the process of gathering materials for the construction of a dolly based on a sketch of one I saw at a Lance dealer in Michigan last month. It will be stored inside my shop on a concrete floor. I plan on constructing the dolly with a hitch so that I can move the unit with my Cub Cadet garden tractor.” – Dave Schwandt, 2015 Ram 3500, 2011 Lance 1181

“I unload my camper with underbelly support. I try to balance the weight between the underbelly supports and the legs. The camper is sitting on wood saw horses.” – Woody Flickinger, 2003 Dodge 3500, 2012 Arctic Fox 1140

“Ours stays on the truck full time. We used to take it off with underbelly support when we had to use the truck previously for masonry construction work. We purchased a new truck for work, so it gets to rest now. It can sit for a couple months at a time, but since the truck is a diesel I start and drive it every other week. It is my daily driver for errands. This keeps the tires healthy as well. When it’s parked, it’s in a 60×30 barn out of the weather and the sun.” – Cheryl Nelson, 2004 Chevy 3500, 1990 Shadow Cruiser 9.5

“If stopped for only a night or two we leave our camper loaded on our truck without the jacks down. If stopped for longer we unload our camper without underbelly support, usually lowering it as much as possible while keeping it level. When it’s stored we support it with 2x6s and aluminum jack stands front and back.” – Paul Turner, 2014 Toyota Tundra, 2014 Adventurer 80GS

“I unload my camper and have homemade sixteen-inch saw horses for underbelly support. I have to support the bottom evenly or I cannot get the door open.” – Ron Beam, 2008 Toyota Tundra, 2010 Palomino B1200

“I store my camper on home made saw horses made from 2X6 with some 8’2×6 long ways.” – Larry Preston, 2013 Ford F350, 2002 Sun Valley 8.65 Apache

“We leave the camper unloaded without underbelly support. We unload and load our camper about once a week. It has gone unsupported as much as two weeks with no problems.” – Jim Kauffman, 2015 Dodge 5500, 2014 Eagle Cap 1160

“It really depends on location, how long the stay, and what I am going to do at that location. Usually I leave the camper on the truck and put the jacks down. It makes it more stable, and also helps to level the camper. If I am unloaded, I put the camper down as low as possible. I do not carry any under body support with me. The camper is pretty stable all the way down.” – Charlie Young, 2005 GMC 2500HD, 2012 White Water 865

“I unload the camper without support.” – Bob Manley, 2012 Ford F350, 2004 Lance 1121

“I built a rolling 4×8 platform that I can store in the pole barn when it’s not in use. I went this route for a couple of reasons. One reason is to keep the camper indoors when it’s not in use and two, to make it easier to roll around in the pole barn if the need arises. I can roll it around myself with ease. I got the idea from another owner on your website. The total cost of the materials (2x8s and four casters) was about $125.” – Mike Shropshire, 2014 Ram 2500, 2014 Palomino SS-1500

“I unload my camper with support. The ground in the storage area is slightly uneven and I prefer to provide the jacks a little relief with a stable underbelly support. One cinder block per corner with a stack jack on each, two 2×6 boards (one front, one back) run side-to-side, and the stack jacks are raised/lowered to keep the camper level. I lower the main camper jacks to just touch with pressure to maintain stability in case the wind picks up. In the end, I have eight points of contact with less stress on the main jacks.” – Barry Edwards, 2014 Ford F350, 2014 Lance 1050S

“I rarely remove the camper. I rarely have the jacks mounted. So most of the time the camper is on the truck with no jacks. But, when I do remove the camper it rests on the jacks with saw horses to provide stability and support across the bottom. The load is distributed about equally on the jacks and saw horses.” – Bruce Heimbigner, 2013 Ford F550, 2013 Phoenix flatbed pop-up

“My 144 year old Lance (in camper years) sits on its jacks off the truck. When it’s on the truck the jacks are up. I do sometimes extend the jacks when camping; either for slight leveling adjustment or cabin stabilization when others are with me.” – Mark Obert, 1999 Ford F250SD, 144 year old Lance 920

“The camper is left on the truck without the jacks down in the summer. The truck is only used with the camper on it, usually every weekend.

In the winter, when we’re five months in deep south Texas, it is unloaded without underbelly support. The truck is used as our daily driver.

With our old 2000 and somewhat tired truck camper we used four screw type tripod supports (the type used to level a RV trailer) with two by eights 24″ under and on top of each screw jack. One would go on each corner of the basement angled so they supported the ends and sides of the camper’s basement.” – Bill Billyard, 2000 Ram 3500, 2008 Palomino Winter Creek 115RS

“I always use the jack stands under the camper when it’s not on the truck. The jack stands take the shake out of the camper when we’re inside and someone is walking. The camper is stored without food or clothing and tanks are dry. Everything else stays.” – Gary Raymond, 2014 Ram 3500, 2006 Lance 1191

“I store the camper off the truck without the use of underbelly support. So far that seems to work well. As the camper ages it may become necessary to provide additional support.” – Dave Riddle, 2015 Chevrolet 3500, 2006 Host Tahoe

“I unload my camper without underbelly support.” – Jim B, 2003 Nissan Titan, 2007 Northstar Freedom

“My camper is usually off my truck without support.” – David and Lila Weinstein, 1999 Ram 3500, Arctic Fox 1150

“I leave my camper in a local storage yard with no underbelly support. I lower the camper as far as I can go. I also store underneath camper a small utility trailer that I use to haul around my golf cart. The trailer is too narrow to allow the camper’s belly to rest on it.” – Donald Kingfield, 2008 GMC 2500HD, 2008 Lance 861 S

“Since I have to use my truck for other endeavors, I unload my Lance 815 and use homemade supports. Sometimes it may be off loaded for several weeks or for just a few days.” – Alex Blasingame, 2007 Ford F250, 2002 Lance 815

“I take my camper off the truck and lower it to within six inches of the ground. That way my waste pipe does not hit the ground. I leave it sit until the next time I am going camping. No support is necessary according to Lance.” – Mike Suan, 2008 Silverado 2500HD, 2010 Lance 830

“If there are two weeks or less until my next next trip, I leave it on the truck. If there are more than two weeks until the next trip, the jacks are down, plus a 4×4 on the jack stands, in a covered storage area.” – Nancy Meiners, 1996 Ford F350, 2014 Lance 1050s

“I have not had the camper off the truck in six years or so. Usually I leave the jacks up, but sometimes will put the jacks down in the driveway to take the load off the truck. We use it so often to camp year round that it never really goes into storage mode. A picture of this rig is in your vintage section.” – Mark Arnold, 1992 Ford F250, 1976 Dreamer (351 years old according to you two)

“I leave my camper loaded on my truck with the jacks down to take weight off the truck’s suspension. My driveway has a slope so it prevents me from leaving the camper without the truck; at least I don’t feel safe doing so.” – Jeff Fung, 2003 Ford F350, 2009 Lance 1181

“For three seasons I leave the camper on my truck without the jacks down. For winter I leave my camper in my driveway on just its jacks. It’s fifteen years old and perfect! Well, there is a dent in the overcab created by me. I hadn’t yet adjusted to no longer having a pop-up truck camper and was taking a friend to the emergency room. I ran into an overhang, but other than that the thing is fabulous! So, there is no underbelly support and no jacks down when it’s on the truck, even in a high wind!” – Michele McLeod, 2013 Ford F150 HD, 2000 Travel Hawk 9.5

“When it’s not in use I store my camper on homemade 2×4 I-beam saw horses with a platform, a 2×6 frame laid flat, sandwiched between 1/2 inch OSB, on top. I made that to raise my camper up approximately 3″ when it’s in the bed. My camper hits the side rails without it. I put the jacks down with no weight on them just in case a strong gust blows through. I lock the nuts on the sides and release the hydraulics.” – Robert Williams, 2012 GMC 3500, 1994 Fleetwood Caribou 9’6″

“Now that I have a tall shop to store the camper, I use a Lance modified metal dolly. I can move it around the shop with a winch. Normally, I only use the Happijacs in the rear when camping for stability. Otherwise, the camper is just mounted on the truck. Keep up the great work.” – C Spansail, 2005 Dodge Ram 3500, 2006 Arctic Fox 990

“During the summer we unload it between trips and allow it to stand only on the jacks. During the winter months (extended non-use) we support it with 2x12s on stacked concrete blocks.” – Stan Smelser, 2013 Ford F350, 2014 Lance 992

“When not in use I unload my camper without underbelly support. Fortunately, I’m able to store it undercover when it’s not being used.” – Rich Downs, 2014 Toyota Tundra, 2015 Northstar 850SC

“Generally, my camper is on the jacks in my barn on a concrete floor when it’s off the truck. I use palates under belly when it’s winterized.” – Virgil Moore, 2007 GMC Sierra 2500HD, 2007 Arctic Fox 811

“I keep my camper unloaded with underbelly support using automotive jack stands (2×8) plank across.” – Tyrone, 2005 Ford F350, 2014 Lance 855

“The camper stays on the truck with the jacks up. My truck is registered as an RV. The DMV says you can’t use the truck without the camper on it.” – Kevin Hasch, 2013 Dodge Ram 5500, 2013 Lance 1172

“In the summer it’s loaded on the truck without the jacks down. In the winter it’s unloaded without belly support and a cover over the camper.” – Erwin Greven, 2002 Chevrolet 2500HD, 2002 Lance 921

“I store my camper with underbelly supports when it’s not being used. This guards against any foul weather that may try to buck the camper around. If I know I will be using it soon, I store it on the truck with the landing gear down. That takes the stress off the truck’s suspension and gives added sway support.” – Monte Dahlman, 2006 Dodge Ram 2500HD, 1995 Skyline Weekender 10’

“For the summer, I usually leave it on the truck without the jacks down. Once in a while I put the jacks down at a campground only because I see others doing that. For the winter it’s off the truck on two sets of store bought jacks with 2x4s running across between the sets. The electric jacks are down, but I try to have the store bought jacks under the belly to take a portion of the weight.” – Marcia Cunney, 2004 Chevy Silverado, 2012 Lance 1050s

“I unload our camper without underbelly support. Having four points of location (goes against nature) I do kick the legs looking for the looser leg then try to adjust slightly to even out the load. I wish there was some type of load indicator on each jack. Supporting on three cannot be good.” – Gary Louthan, 2013 Ram 3500, 2009 Lance 830

“We leave our camper on the truck without the jacks down. I have had fifth wheel rails installed so I have a plywood with 2×4 cross pieces to raise the bed above the fifth wheel rails. Consequently when I remove the camper, I place the plywood on saw horses and just rest the camper on it.” – Bil Ball, 2011 GMC 2500HD, 2014 Travel Lite

“I have made my own steel saw horses to store our camper. I remove the four jacks, which I have modified to be quick release. The camper is rock solid on the saw horses. My wife and I have recently finished living full time, eighteen months, in our camper parked while we waited for our apartment to be built.” – Chris Smith, 2008 Ford Ranger, Adventure 76R

“When we store the camper off the truck, we use a custom made dolly, sized to clear the roofline of the Morton building where we store the camper out of the weather. We used the running gear from a flatbed hay wagon since these are designed to hold several tons of hay. It was custom re-engineered for us by a local welding shop and contractor.

When in use, we share the weight of the camper between the jacks and the dolly. We use a compact John Deere tractor to maneuver it around.” – John and Marylou Wells, 2011 Chevy 3500, 2012 Chalet Ascent S100F

“I unload it with underbelly support.” – Cecil, 2001 Dodge Ram 3500, 1999 Lance 1030

“My camper is 35 years old in human years. I use all four options depending on the situation . When go out I leave the camper on the truck without jacks. I like to stay in BLM areas for a few days at a time. I use the jacks while the camper is on the truck when I need to get closer to level. When unloaded I use supports for not occupied temporary situations only. I use underbelly support when camper is off for more than a couple of days.” – Rag, 2003 Chevy Silverado, 1980 Sportsman 8ft

“For the short term I leave my camper loaded on the truck without the jacks down. For the long term I leave my camper unloaded on a homemade heavy-duty sawhorse and the jacks on the front. The jacks are down on the rear.” – Trekker Hill, 2002 Dodge Ram 2500, 2004 Lance 920

“We leave our camper in the backyard hooked up to power when it’s not being used.” – Mike, 2015 Ram 3500, 2013 1050S

“I typically store the camper on three metal saw horses with the jacks down. But right now I have an extra F250 and the camper is sitting on it with the jacks up.” – Kevin Snyder, 2004 and a 2012 F250, 1998 Lance Squire 3000 8′ 6”

“I store the camper on underbelly supports because I have an old tripod leg system.” – Bob Bergen, 2003, Chev Silverado, 1986 Real-Lite

“I leave my camper loaded on my truck without the jacks down.” – Mitch Johnson, 2015 Toyota Tacoma, 2015 Four Wheel Campers Fleet SC

“I unload and supported the camper with four 6×6 (22″ high) and two 2×4 across the bottom.” – Ernest Wallace, 2006 Chevy 2500HD, 2005 Lance 881

“At this point I leave the camper loaded in the truck. The jacks are down for stability since it’s my primary residence and the jacks are old and pretty much shot. I need to jack them up daily to keep its stability since it’s 216 by camper years.” – DuWayne Hermann, 1996 Ford F150, 1993 Fleetwood Elkhorn

“The camper is left on the truck without the jacks down. It is a shell model and light enough to leave loaded on the truck. That way, when I am ready to take off, it is ready to go!” – Tom Waters, 2003 Dodge 2500, 2014 Four Wheel Camper Grandby

“I unload the camper with underbelly support using home made sawhorses.” – David Drew, 2011 Ford F350, 2005 Travel Lite 11’

“I unload my camper with underbelly support. I use two 2” square steel pipes bridging cinder blocks. The weight of the camper is taken off the legs, but it is still attached.” – Dan Griffin, 1996 Dodge 2500, 1992 Skamper

“My camper is loaded on the truck without the jacks down.” – Don Grint, 2005 Dodge 2500, 2013 Arctic Fox 990

“We keep our truck camper on the truck, except for maintenance. I feel that it’s safest to store that way, plus it’s out of our way. If we didn’t use it so often, I’d place bottle jacks under the rear truck frame and take the load off the truck’s rear springs, but it’s too much bother, so we don’t.

I’ve made a pair of X-style plywood stands for the truck camper whenever we do pull it off the truck.” – Bruce and Kathy Allison, 2000 Ford F350, 2012 Adventurer 910 FBS

“I unload the camper without underbelly support. The jacks are retracted to 6″ from ground.” – Tom Evans, 2004 GMC 3500, 2005 Lance 920

“We use a pair of Stablemate saw horses. They are only rated at 500 pounds, however from experience I know they are good and stable to well over 1200 pounds each. No matter how stout the supports are, I still leave a leave just a little load on the jacks.” – Matt Wiegand, 2014 Ford F-150, 2015 Palomino SS-1251

“We installed the Stable Lift hydraulic jack system. It’s fully lowered using the three all thread cross braces, but no under belly support.” – DeWayne Brown, 2014 Dodge 3500, 2007 Capri Rodeo Delux

“Currently we store our camper at a storage lot primarily to not incur the wrath of our HOA. So, the camper is off the truck and lowered to the ground for stability reasons. Our intention is to buy, or make, a sawhorse and platform type of underbelly support. I have trouble believing that the camper will always be okay, over time, without this type of support when it is off the truck. We are anxious to read what other truck campers have to say about this issue.” – John and Terri Tully, 2014 Dodge 3500, 2015 Lance 855s

“During the summer I lower the camper, leaving it on the jacks only. For winter storage, I support the camper on three 4X6s on jack stands. The driveway is not level so the jack stands allow me me to adjust and keep the camper level. Then, I lower the camper jacks to the ground just enough to stabilize the camper. The owners manual emphasizes to make the 4X6s long enough to span the entire width of the camper because the center of the floor is not strong enough to set the camper on.” – Bryce Dillree, 2007 GMC 2500HD, 2013 Wolf Creek 850

“We unload our camper without underbelly support.” – Todd Russell, 2004 Ford F250, 2006 Travel Lite

“I store my camper in a fully enclosed and locked RV storage facility. It is unloaded from my truck and placed on cinder blocks and 2x6s fully supporting the underbelly with the jacks deployed for added stability.

When I am camping for more than a week and need my truck for transportation and boat launching, l will unload my camper and fully support the camper belly with pedestals and 2X6s with the jacks deployed for added stability. I fabricated the pedestals from sheet aluminum and they nest inside each other for storage in the camper. Note that not all RV Parks will allow you to unload your camper.” – Doug Diehl, 2010 Ford F450, 2011 Chalet DS116

“We always unload our camper and leave it on the jacks with the jacks in the lowest possible position. We do not put anything under the belly. We also recently had a RV carport installed, so from now on it will be under a roof at all times when it’s not in use.” – Rick Guffey, 2012 Ram 2500, 2013 Hallmark Everest

“We leave the camper on the flatbed during the summer when we use it most. When we take it off, we store it in a barn on sawhorses. Dan made the sawhorses out of 4X4 lumber. All the jacks are down, but the weight is on the sawhorses.” – Dan and Peggy Sego, 2005 Dodge 3500, 2011 Lance 992

“We unload our camper after each trip and leave it on the jacks without supports. Our camper spends more time off the truck then on, because we unload if we’re staying in one camp more then a couple of days. That’s why we have a pop up easy on and easy off.” – Eddie Hayden, 2005 Dodge 2500, 2012 Palomino Bronco

“We store our camper loaded for the short term on the truck with the jacks down to take some, not all the weight, off the truck. Winter the camper comes off the truck on 6×6 cribbing, which is full basement support. All things that will freeze are emptied and used or stored until next season.” – Jay B. Brower, 2013 Chevy 3500, 2014 Chalet TS116

“Right now, I don’t have a storage building for it. I also live in the Rust Belt. My truck is from Oregon and is rust free and I intend on keeping it that way by not driving it in the winter months. As a result, I leave the camper on the truck with the jacks up during the winter. My reason for leaving the jacks up is that the entire unit can then respond to wind gusts.

My wife and I are planning on building a storage building for the camper (and other items) next year. When it is done, I will store the camper on a 1/2″ piece of plywood with 1×2 furring strips between the camper and the plywood. The plywood will rest directly on the concrete floor. I will put the jacks down to distribute the camper’s weight over its entire structure. The furring strips will promote air circulation under the camper’s belly.” – Arn Chamberlain, 2000 Ford F-250, 2004 Palomino Maverick 8801

“I store my camper with the legs down on a table the same size as the truck’s bed.” – Gary Goyette, 2011 GMC Sierra 2500HD, 2012 Northern Lite 8-11

“We leave our camper loaded on the truck without the jacks down almost all the time. When we do occasionally need to remove it from the truck, it is stored inside our garage without underbelly support.” – Buzz and Sherri Merchlewitz, 1998 Dodge Ram 2500, 2015 Hallmark Ute

“I unload the camper without underbelly support as close to the ground as possible. I live in Maine, so I cover the entire camper with a complete cover for the winter months. I love my camper. It’s better made than any of the new ones being made now. Quality is great compared with new ones.” – Roger Couturier, 2012 Ford 250, 2001 Lance 1030

“Leaving the camper on the truck, I disconnect the tie-downs and put the jacks down to take part of the load off the truck. Off the truck, most of the weight is supported on sawhorses, with the jacks down supporting part of the load. In both cases, the unit is indoors, on a concrete floor.” – Alan Hubbard, 2004 Silverado 2500HD, 1993 Sun Lite 951

“I unload the camper without underbelly support.” – Charles Coushaine, 2001 Ford F350, 2012 Chalet DS116RB

“I lower mine onto saw horses with 2x6s on top to take some of the weight off the jacks. But still the jacks lose pressure and the saw horses sink into the gravel drive over time. It worries me. I would like a full stand to put it on for long term winter storage.” – Dave Arnold, 1998 Ram 2500, 1991 Caribou

“Two ways. If we’re using it regularly, we leave it on the truck mostly with the jacks down. If we’re not using for a while, or we need the truck for another use, the camper comes off the truck without underbelly support.” – Carol Bowman, 2005 Dodge 3500, 2014 Lance 1191

“My camper is off the truck, sitting on a homemade base. I use 4×4 posts at the corners and framed them with 4′ X 8′ frame of 2×4’s to support the camper floor. All the weight of the camper is on the base I built. Jacks are set right at ground level, but have little to no weight.” – Chris Harlan, 2003 Chevy Silverado 3500, 1991 Lance 900

“We unload home built saw horses for underbelly support. The jacks are down for added stability. It’s windy in Wyoming.” – Bob Watts, 2011 Dodge Ram 2500, 2000 Fleetwood Angler 8

“I unload each time we come home. During camping season, from April to November, the camper sits on the jacks without under belly support. During off-season, I place supports under the belly to take a little of the load off jacks.

New for this year to stabilize the unit when camping, I’ve started lowering my rear jacks to the point they just the ground. I really like the solid feel when walking around. I level the truck first, then the loosen turnbuckles, and lastly lower the jacks. It only takes a couple of minutes.” – Thomas Wilson, 2015 Chevy 3500, 2015 Adventurer 89RB

“I store our Bigfoot on two sawhorses. I also keep the jacks down with just a little weight on them for increased safety and stability. I bought the Super Steel Sawhorse Brackets from Home Depot for $118 for a pair. These are rated to 4000 pounds, plenty enough to hold my camper. When traveling I store the disassembled sawhorses in the truck on the side of the camper.” – Jim Marquart, 2002 Chevrolet 2500HD, 2002 Bigfoot 25C10.6E

“The camper is parked outside, off the truck with no support and no cover over it. It stands on the jacks alone. This camper has been to Baja many times over rough washboard roads and north to British Columbia and every place between. Everything still works fine. I would really like to get the 1172 model if I can find a truck with the payload for it.” – Steve Brant, 1995 Ford F250, 1997 Lance Squire 9’10”

“We store our Northstar 850SC with support or not, depending on the season. One advantage we like about our pop-up is that it is stable on its jacks when lowered close to the ground (using the bumper step).

We do not use supports in this mode if we unload it while we’re on the road or if it’s stored in the barn (large garage) during the travel season. However, during the winter months, we support the camper floor with cider blocks. We stack two blocks high under each corner and two in the middle along the outside edge (north/south). We put three 2x8s on top of the blocks running across (east/west), extending out past the bottom edges of the floor. The camper sits easily on this arrangement with the jacks off the ground and we can stack the blocks in the garage corner out of the way during the summer.” – Dave and Carolyn Thalman, 2013 Ram 2500, 2013 Northstar 850SC

“Our camper is unloaded with underbelly support. I use jack stands to get it low to the ground for access. I also put down the jacks to add balance support.” – Pat Caulfield, 2008 F450, Okanagan 117DBL

“My camper and truck live in a 14′ x 40′ enclosed storage unit. I always lift the camper a couple of inches above the truck’s bed to keep the weight off of the truck, however I leave the truck under the camper in the event of a camper jack failure. Your question this week is very timely since I have recently been considering unloading the camper and setting it on some sort of under belly support thus taking the weight off of the camper jacks as well a the truck. I, like many, am also wondering what would be the best support system. Thanks for a great website. Keep up the good work.” – Gary Richardson, 2006 Chev Silverado 3500, 2006 Lance 1181

“I unload the camper with underbelly support, using two heavy duty pressure treated 25″ tall saw horses with a 3/4″ piece of 4’X8′ sheet pressure treated plywood underneath. The saw horse under the front of the camper has some 4″ blocks underneath it so the front of the camper is a bit higher than the back. This is what the Bigfoot Company specified as the preferred method of long term storage.” – Bob Walsh, 2013 GMC Sierra 3500, 2003 Bigfoot C2510.6E

“I mounted my truck camper on a gooseneck twenty-four foot low boy trailer, with under belly support. I am able to take my Jeep with me, and have a very large back deck once I unload the Jeep.” – Michael E. Parr, 1998 Dodge Ram 2500, 2004 Sun Valley Sun Lite 865

“I leave my camper on the truck without the jacks down.” – Piet Jan van der Bas, 1997 Landrover Defender 110 HCPU, 1994 Shadow Cruiser pop-up

“I unload the camper and use four six-ton jack stands with 4x4s to support the camper. Additionally, all four jacks are down and holding weight, but the camper doesn’t rest exclusively on the jacks.” – Mark Joslin, 2006 Dodge Ram 3500, 2005 Lance 1181

“During the in-use season I leave it off the truck on the jacks. In the dead of winter I use three sets of cinder blocks with a 2X6 between each set. This supports the camper in three places as recommended by the manufacturer. I leave the jacks down with just a slight amount of pressure on them.” – Ken Werner, 2003 Dodge 3500, 2015 Wolf Creek 840

“When the camper is not on the truck, it’s just sitting on the jacks without any additional support. I don’t want to put the weight on a sawhorse since I’m not sure where the supports are in the floor of the camper. I could do more harm than good. The only way I’d place my camper on a support is if the support covered the entire bottom of the camper, similar to sitting in the truck.” – Phil Rodacy, 2012 GMC 3500, 2006 Okanagan 90W

“I unload my camper without underbelly support.” – John Bull, 2004 Dodge 3500, 2015 Arctic Fox 990

“If it is on our truck with no plans of using for a short or long term, the jacks are extended to take the majority of the camper’s weight off of our truck’s suspension. If our camper is off of our truck, it is dropped to a lower height and is supported by three-quarter inch thick plywood that is approximately two feet by four feet with a notch cut out of each so they slip together to form two X panels. These are placed under our camper, front and rear to supply additional support with its jacks. These four panels lie flat under our camper when we travel. These have been used for the past two seasons with no problems when we unload at sites and want our truck to travel with.” – Eric Devolin, 2007 GMC Sierra 3500, 2006 Adventurer 106 DBS

“I leave the camper on the truck, and then jack up the truck with a floor jack and block it to take the weight off the springs and tires. It’s faster than using the camper’s jacks.” – Dennis Thorell, 2010 Chevy 3500, 2009 Northern Lite 10’2”

“I unload my camper without underbelly support.” – Michael White, 2004 Dodge Ram 3500, 2011 Arctic Fox 990

“In the northern California foothills after four years of drought, our camper lives on our F450, with the jacks up, in case we need to evacuate quickly during the fire season. During the rest of the year, if we’re not traveling, the camper lives off the truck without underbelly support.” – George Dunstan, 2009 Lance 1055

“We leave our camper off the truck with most of its weight on blocks of wood underneath it and the jacks down to help stabilize it.” – Tom Bushman, 2015 Ford F350, 2009 Lance 1040

“We leave our camper loaded on the truck without the jacks down.” – John and Lorrie Sipos, 2012 Ford F350, 2013 Lance 992

“So far it has stayed on the truck with the jacks removed.” – Ed Osborn, 2007 Chevy Silverado, 2013 Four Wheel Camper Raven

“I unload my camper with underbelly support.” – Gordon Hansen, 2015 Ram 3500, 2008 Arctic Fox 811

“My camper is unloaded without underbelly support.” – John Walicek, 2014 Ram 3500, 2009 Lance 815

“My camper stays on the truck all the time, without the jacks down.” – Scott Notar, 2001 Ford F250, 1997 Northwood 10ft

“We store it off the truck with underbelly support.” – Chris Adams, 2010 Ford F250, 2012 CampLite 8.5

“We lower it down and it is sitting only on the four legs.” – Ralph Beam, Dodge 2500, 2006 Lance 845

“My camper is in an enclosed carport, on the jacks.” – Jim Thomas, 2013 Ford F350, 2013 Host 9.5

“We don’t have jacks on our camper, but unload it onto a cart we can roll around in our storage building. The camper stays on the truck from late March to late November most years.” – Laurel Wilson, 2013 Ford F350, 2000 Four Wheel Grandby

“During the summer months I leave my camper loaded on the truck without the jacks down. I like to keep it ready for weekend trips and as an emergency shelter during power outages and/or natural disasters. We have many earthquakes daily here in Alaska.

During the winter months I store my camper on stacked composite pallets with six 3″x6″ timbers to support the camper. It is also ready to use as an emergency shelter during the winter minus the water system.” – Allen Jedlicki, 2012 GMC Sierra 2500HD, 2014 Wolf Creek 850SB

“I leave mine on a 10’x20′ concrete slab, on its own jack stands. Plus, I have a cargo bar upright and centered under the cabover. It’s very stable.” – Tom Miner, 2004 Dodge Ram 3500, 2005 Host Yukon 11.5 SS

“When I’m not using the camper for an extended period or when I want to use the truck as a truck, I park the camper under an open car port using the jacks. Then I then lower it down onto under belly support which is strongly recommended by the factory.” – Steve Timmings, 2003 Ford F350, 2013 Four Wheel Hawk SC

“My camper is loaded, with the jacks up.” – Tom Scholtens, 2010 Chevy 2500HD, 2013 Bigfoot 25C104

“We leave the camper in the truck with the jacks up and everything ready to go except food inside it.” – Bill Hornung, 2002 Chevrolet 3500, 1997 Vanguard c11s

“My truck camper stays on the truck 24/7. I put the jacks down over winter to give the truck springs a bit of a break. The rest of the time, the truck carries all the weight.” – Maaja, 2012 GMC 2500, 2015 Northstar Liberty

“It depends on the length of time it will be sitting. For prolonged periods, like over the winter, we would use underbelly support cinderblocks with wood on top. For short periods, like weekend camping, we would use the camper without underbelly support.” – Deb, 2009 Chevy Silverado 2500HD, 2002 Lance 845

“If we know that we will be using the camper again within the month, we just leave it on the truck with the jacks up. Our jacks are not electric so taking it off and putting it on the truck is a pain in the neck.

If we do take it off the truck, in the summer time, we simply leave it supported on the jacks, but we do lower it down as close to the ground as possible just so it is more stable.

When winter comes, we store it on a frame made of concrete blocks and treated 4x4s. The frame is made to align with the perimeter of the bottom of the floor so it is supported around the perimeter. There are no support boards criss-crossing the bottom of the floor (this may be a mistake). Once it is sitting on the frame, we lower the jacks to the ground and provide some light support using those.” – David Miller, 2012 GMC 2500HD, 2012 Travel Lite 890SBRX

“We store the camper off truck. We use three 8×8 inch beams supported two cinder blocks each. This allows fourteen inches or so of space under the camper. We also use an Adco cover to protect the camper from the winter weather in Boise, Idaho.” – Dave Erickson, 2011 Ford F350, 2006 Arctic Fox 990

“We unload our camper when we’re not using it and support the underbelly with aluminum stacker jacks and 4x4s. The support helps steady the camper. We lower it so the first step is about four inches off the ground. The jacks and 4x4s store in the basement if we decide to remove the camper when we’re traveling.” – Bob and Cathy Grey, 2011 Ford F350, 2008 Bigfoot 25c-10.4e

“I unload the camper without belly support. Also I do not keep a level roof, but have the camper with a good slope to keep the roof drained.” – Firman Schiebout, Ford F350, Northstar 9.5 Igloo U

“We just winterized for this year and decided to put the camper on front and back store-bought saw horses. The electric jacks are just touching the pads for added support.” – Tim Chapell, 2013 Ford F150, 2013 Palomino SS-1251

“I store my camper on a 16″ high 2×4 rectangular frame that’s 48″ wide. The front one is just 2×4 width and carpeted, and the rear is carpeted with a 8″ high step built into it. I usually settle the camper with a least a two to three inch slope front to rear to help shed snow and water. I tighten down the roof vent cover with Max Air rain covers and leave the camper uncovered so that it does not rub the finish off the fiberglass exterior. It stays dry as a bone all winter long.” – William C. Steger, 2005 GMC 2500HD, 1995 Kodiak SC83

“I leave my camper on the truck most of the time all spring, summer, and fall. If I do take it off I have a set of support boxes that are slotted to hold a 2X6 cross support board. One set is different heights to keep the camper level on the slope of my driveway. One set is the same height to keep it level during winter storage at my daughter’s house. I also keep the jacks down for additional support whenever the camper is off. I have never used the jacks after I have it loaded. I take the manual jacks off to save some weight when traveling.” – Mike Pohl, 1999 Ford F150, 1985 American Pilgrim 8.5 Hard side

“I unload the camper in a garage without underbelly support.” – Robert D Mayton, 2014 Ford F450, 2014 Lance 1172

“I had a Zizzer lift wear out. I saved the bottom and set the camper on it.” – Dennis Duncan Jr, 2012 Ford F350, 2005 Arctic Fox

“Our cell is fixed, so the problem does not exist. We start and go away.” – Frederic Amorós, 2011 Toyota Hilux, 2011 PSI – AZALAÏ, (France)

“My camper is parked inside all winter on four 16″X16″ cribbing stacks made of 2X4s. One is on each corner of the floor with the jacks up.” – Brad Cary, 2009 Chevrolet, 2008 Lance 835

“When the camper is not on my truck I use a custom stand that I built from construction scaffolding. I used what is called half high scaffolding and then mounted a 2″ x 2″ x 1/4″ thick steel tube to support the camper at the front and the back. With this system I can level each corner as required and I only need to lift the camper high enough to get the truck out. I place a couple of 2 x 12’s underneath to set the camper on. It’s more for piece of mind than anything else.” – Kelsey West, 2000 Ford F350, 2011 Northern Lite 9-6QCSE

“I have the camper unloaded without underbelly support since we purchased it new in 2002. There have been no issues. Previous to this camper we owned a 1978 Lance and did support the camper when it was not on the truck. We used blocks located at each end and in the middle.” – Mike Paulucci, 2013 GMC Sierra, 2002 Lance 915

“The biggest single enemy of any RV is water damage. I worked in the RV industry for many years, and if you wish to extend the life of your truck camper, storing it in a shelter that prevents the unit from being exposed to the weather when not being used is the best prevention you can provide.

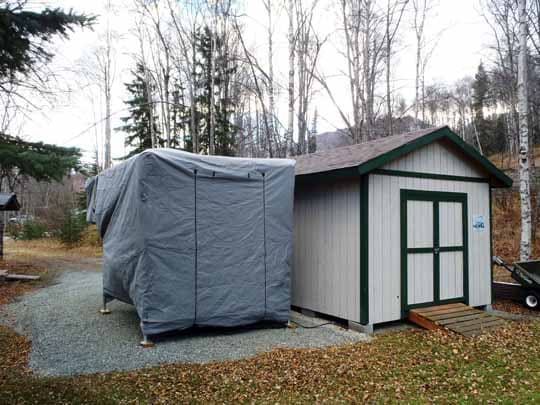

As for storage, our camper is placed on our truck in the spring and removed in the fall. The camper sits inside of a 12 x 26 RV port when it is not being used. The truck and camper stay under the port when the camper is on the truck. In the winter when the camper is off of the truck, the camper is under the port and the truck is in the garage.

When the camper is off the truck we place four cinder blocks with two 2 x 8 boards to support the front of the unit. I don’t worry about the rear of the unit since the rear jacks attach to the camper on the sides of the unit and also to the bumper. We lower the unit as low as it will go until the exhaust on the generator is about two inches from the cement floor in the port. The camper is very stable with the four jacks and the blocks in the front. We also use two sets of Torklift Wobble Stoppers on the front jacks. They prevent excess stress on the unit when the jacks are in the extended position, such as loading and unloading.” – Charles Spray, 2002 Ford F350, 2001 Lance 1010

“I leave it unloaded on the jacks. There is no underbelly support, but I do lower it to within a foot or so of the ground.” – Dale Wilmot, 2007 Chevrolet 2500HD, 2012 Lance 992

“When my camper is not on the truck I use three saw horses that I made that fit under the front, center, and rear of the camper. It is stored inside my machine shed out of the weather. The saw horses are tall enough that I do need not crank down my jacks to get the truck under the camper when reloading it.” – Dan Forry, 2004 Ford F250, 2006 Palomino 1251

“Mine, since new, sits on the jacks with no belly support, when it’s off the truck, which sadly, is most of the time. I keep it as low to the ground as possible.” – Ron Williams, 1997 Ford F250, 2003 Lance 1010

“I leave my camper on my truck with no jacks down.” – Robert Martin, 2008 GMC 2500, Northstar Laredo SC

“Most of the time the camper is on the truck with the jacks up. If I off-load it for winter storage, mid November-January, I use underbelly support of concrete blocks stacked four high on each corner with a three inch by fourteen inch by five foot long board on top of the blocks for support. I keep the jacks down on all four corners which rest on 6×6 wooden blocks for additional stability. I keep the truck and camper under a twenty-six foot aluminum canopy.” – Roger Odahl, 2008 Dodge Ram 3500, 2004 Eagle Cap 950

“I leave my camper with underbelly support, which is a wood frame. The jacks are extended, but weight resting on the support. The jacks provide stabilization while on support frame.” – Jim Wenner, 2006 Chevrolet Silverado 2500, 2007 Arctic Fox 811

“Sometimes we leave our camper on our truck and put the legs down to take pressure off the truck. We also store it off the truck standing on its own legs, but we do lower it down so it’s not sitting so high. We have also camped in it on the truck but, once again, we put the legs down for stability. Actually we would really like to know what is the best way for the unit.” – Diane Dixon, 2009 Toyota Tacoma, 2014 Northstar 600ss

“When we don’t have a trip planned for a couple of months, I unload the camper without underbelly support and leave it on the jacks. If another trip is planned, it will just stay on the truck without jacks. I always take the jacks off when the camper is on the truck because they weigh 98 pounds. I can’t afford that much unnecessary weight.” – Gary Scott, 2015 Toyota Tacoma, 2014 Four Wheel Camper Eagle

“We unload the camper without underbelly support. However, I make sure it is level. Norcold refrigerators do not like being tilted.” – Wade and Becky Johnson, 2004 Ford F350, 2004 Lance 1130

“I unload my camper with jacks down and without underbelly support for about six months.” – Ralph Goff aka Ramblin’ Ralph, 2006 GMC 2500HD, 2001 Lance 845

“BOA (Bug Out Anytime) stays on our rig all the time, without the camper jacks. We keep emergency equipment, and some MREs in the cabinets. We keep nothing in the refrigerator, but keep a case of water on board. We are ready at a moment’s notice!” – Mike Kolinski, 2012 GMC Sierra 2500HD, 2012 Four Wheel Camper Hawk

“We unload our camper without underbelly support. Great timing for your question. We’ve been wondering if we should have underbelly support and what would be best.” – Tony and Linda Perez, 2014 Chevy 2500HD, 2013 Wolf Creek 850

We own two campers, and we have applied lessons learned from our 1998 Coachmen onto our new 2014 Lance 1050s.

Since 1998, we have stored and camped in our Coachmen with the camper standing only on its four legs (no external underbody support). When we bought the camper new, Coachmen was still manufacturing truck campers and they had a dedicated engineering group for these designs.

I actually called Coachmen engineering soon after we received the unit and asked about walking, living, and sleeping in the Ranger with the camper unloaded from the truck and set only on the four legs. They responded that this was the design intent and would be no problem, if the unit was lowered as close to the ground as possible and was level over reasonably level ground. That was how we used the camper until 2014. Even on road trips, we set the Coachmen on the ground, leaving the truck free for local exploration. The camper became a self-contained cabin to come home to.

However, nothing lasts forever, and in early 2014, I noticed that the front legs were beginning to tilt forward a bit. When the weight was taken off those Atwood Jack legs, it was apparent that the leg bracket bolts holding the highly loaded jacks onto the camper body were working loose and allowing the front legs to shift slightly. Those carriage bolts were installed through the square aluminum tubing inside the body structure and, after sixteen years of use, that tubing was starting to deform under load.

So, we bought a new Lance, but still loved the old Coachmen. I couldn’t sell that camper with this known defect, so we came up with the repair shown in the three photos. Removing the front jacks and their associated brackets, we manufactured aluminum plates to fit over the exterior body of the camper, larger than the surface area of the standard front brackets. These new plates, both on the sides and front of the corners, were solidly glued and bolted using new bolts into the underlying frame. I drilled to allow the original mounting bolts to pass through these new plates. The factory-original brackets and front jacks were remounted so that the load was shared across the new plates and distributed over a wider area of the front corners.

If you look carefully at the photos, you can see the original jack brackets mounted on top of the larger underlying metal reinforcement plates. When painted, you can hardly tell they are there.

The first time we applied the camper’s weight to the front jacks, it was obvious that the mount was infinitely stiffer. The legs exhibit no shift or tilt. It’s rock solid, and better than when it was new, in my opinion.

After that experience, I was confident enough to make that same modification to our brand new Lance 1050s, even though there was no indication of a problem. The front legs react most of the camper dynamic loading and static weight, and distributing that load over a wider area greatly relieves the point stress at the attachment bolts.

I can’t be the first person to accidentally get the camper up on three legs, where one of the rear jacks retracts faster than the other, leaving the camper standing on two front and one rear leg. The body structure is strong enough to do hold the unsupported rear corner in the air. However, you won’t be able to get one front leg into the air, and please don’t try it. The front loads are just too high, the center of gravy is too far forward, and you risk tipping, rolling, or structural failure. Because the rear legs are relatively lightly loaded, there is no reason to worry about a stiffener modification on those legs.

Getting back to your question, I can say that both campers stand on their own four feet, off the truck, lowered close to the reasonably level ground, most of the time. I’ve never put any support under the belly of the campers, and don’t plan to. I once saw a photo of a camper that was set on wooden pallets, after the pallets had shifted in the wind/rain, allowing the camper to slip/slide sideways, tearing the front leg out of the frame and destroying the front panel. The legs are very stable when solidly on the ground, but cannot stand much of a dynamic impact when retracted.

Since that time, we’ve installed a new roof on the Coachmen, had the front window removed and insulated, installed LED lighting, and closed the now windowless front end with a solid wrap-around composite sheet. After adding some new decals, the old girl looks great. I still keep the propane tanks full, as she’s fully repaired, functional and ready to go. But, that also means she’s ready to sell. I guess I’ll soon need to start working on an eBay ad.” – Gary Possert, 1998 GMC K3500, 1998 Coachmen Ranger

“We live in Alaska, so a sturdy base is necessary to withstand winter weather. Since we use our camper for half or more of the year, we typically put it on its base only once or twice a year.

I built a small, portable deck that sits on four poured concrete footings complete with leveling hardware. The deck is 4′ x 8′ and is constructed of two 4″x6″ beams running lengthwise, with 2x6s on 16″ centers mounted in joist hangars on the beams, just like a deck or floor.

To keep it light, all things relative, I didn’t fasten the 2×6 joists to the joist hangars so they can be removed. To keep the deck rigid, there is a piece of 1/2″ all-thread that is through-bolted through the beams at each end. When the 2x6s are dropped into the joist hangars and the all-thread tightened, it is very rigid.

To use it, I back the camper into the spot where I want to drop it, raise it off the truck and pull the truck out. Then I drop the four concrete footings in place, put the deck beams into the leveling U-saddles on the footings and square/level it up. If the 2x6s aren’t already in place, they are dropped in next. This takes about twenty minutes if the spot isn’t fairly level.

Once the deck framing is complete, square and level, I place a sheet of 4’x8′ OSB, like roof or floor sheathing, on top of the deck and then place a piece of 2” thick 4’x8′ rigid foam insulation on top of that. Then I lower the camper in place, raising the jacks about an inch off of their pads in case the deck settles over time. I don’t want one corner sinking enough to put that load on a single jack.

Remember, we live in a cool climate, and the foam board is for extra insulation in the unlikely event we would need to inhabit our camper in an emergency. It helps insulate the basement where the holding tanks reside.

And yes, we have camped for days in it in -20F temps and it was great. One winter I tested the forced air propane heating system at -45F one winter, and with both twenty pound propane tanks full and married together, it took thirty minutes to get up to 55F, and ultimately shut-off at 68F in forty-five minutes where the thermostat was set. It’s very usable in an emergency, although I would need a 100 pound or larger propane tank to sustain this and live in it.

This deck stays at home. It was not intended as a portable or temporary base to take on camping trips.” – Bill Wakefield, 2001 Ford F350, 2001 Bigfoot 20C 8.10

“Here is a picture of our 2012 Lance 850 on our 2011 Ford F-350 in the storage yard. I do not dare put the Atwood jacks down for fear that I will drive off with them down!” – Bob Morrissey