Four Wheel Campers has made a number of significant changes across its entire line of lightweight pop-up truck campers for 2018. They’ve also updated their building, added new CNC equipment, and started the path to 5S and lean manufacturing.

This is not your typical annual manufacturer update. Yes, Four Wheel Campers has some important updates to their product line to share, but those changes are part of a more significant shift happening in Woodland, California.

It would be easy to dismiss the new plant signage, new office furniture, and new production floor equipment as just part of the 2016 acquisition by Salt Creek Capitol. As many things are in life, this quick answer would be far from the complete picture.

So what’s really going on in Woodland, California? Nothing less than a reinvention. Every facet of the Four Wheel Camper company, product, and culture is being reexamined, challenged, and pushed forward.

The new management team is methodically implementing new manufacturing concepts, new business strategies, and new operation approaches designed to take an already strong company and make it into a world-class manufacturer.

For Four Wheel Camper customers this means improved quality and quality control, improved availability and delivery time, and improved documentation and presentation. Essentially, take every aspect of the Four Wheel Camper product and experience and take it up a notch, or two. Then keep going with a culture of Kaizen; continuous improvement. If that sounds like something from the automotive industry, it is.

To dig into the specifics of the product changes for 2018, we talked to Dan Welty, Vice President, and Stan Kennedy, Sales and Marketing, for Four Wheel Campers. We start with the new propane and plumbing lines and wind up in 5S and lean manufacturing. Hold on Four Wheel Camper fans. Big changes ahead.

Above: Pre-assembled flexible rubber propane lines

TCM: For 2018, Four Wheel Campers is changing its propane lines from copper to flexible rubber lines with a new manifold system in all campers built for their US customers. How are the new flexible lines different than the outgoing copper lines?

Stan: The flexible rubber propane lines are easier to manufacture than the copper lines and the quality is more consistent. The copper lines were extremely reliable but were hand-built for each specific camper. This involved some complex runs and bends through and around cabinets and various components.

Rubber propane lines are becoming an industry standard. They are pre-manufactured and utilize screw-on connections. The rubber lines are also not going to kink like propane lines can, and are more durable and easier to maintain for the customer.

Dan: Less angles mean propane flows better with the rubber lines. We are also saving three to four hours of manufacturing time per camper with the rubber propane lines.

Above: The new propane manifold

TCM: What are the advantages of the new propane manifold?

Dan: Again, production quality and manufacturing efficiency. With the copper lines, we had to hand-build so many different size lines for each individual camper. The new rubber propane lines and manifold system is assembled ahead of time, installed in the camper, hooked up, and then pressure tested.

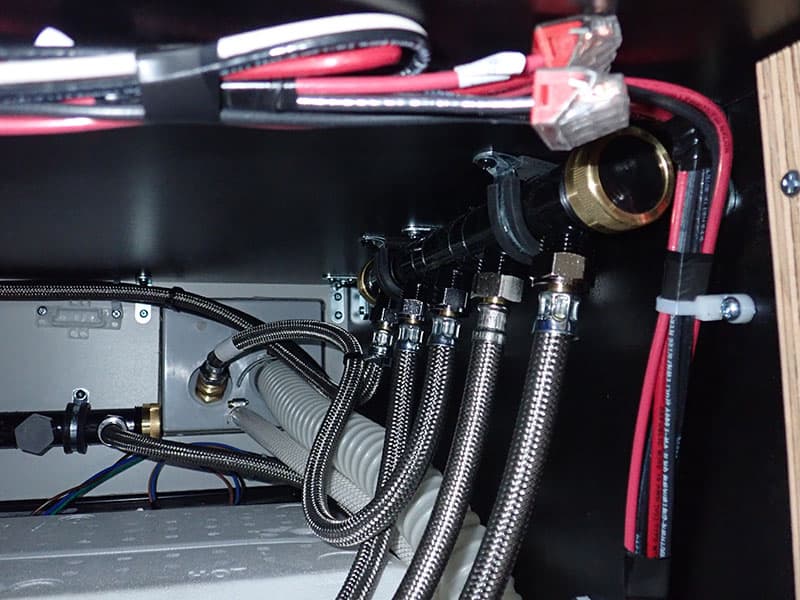

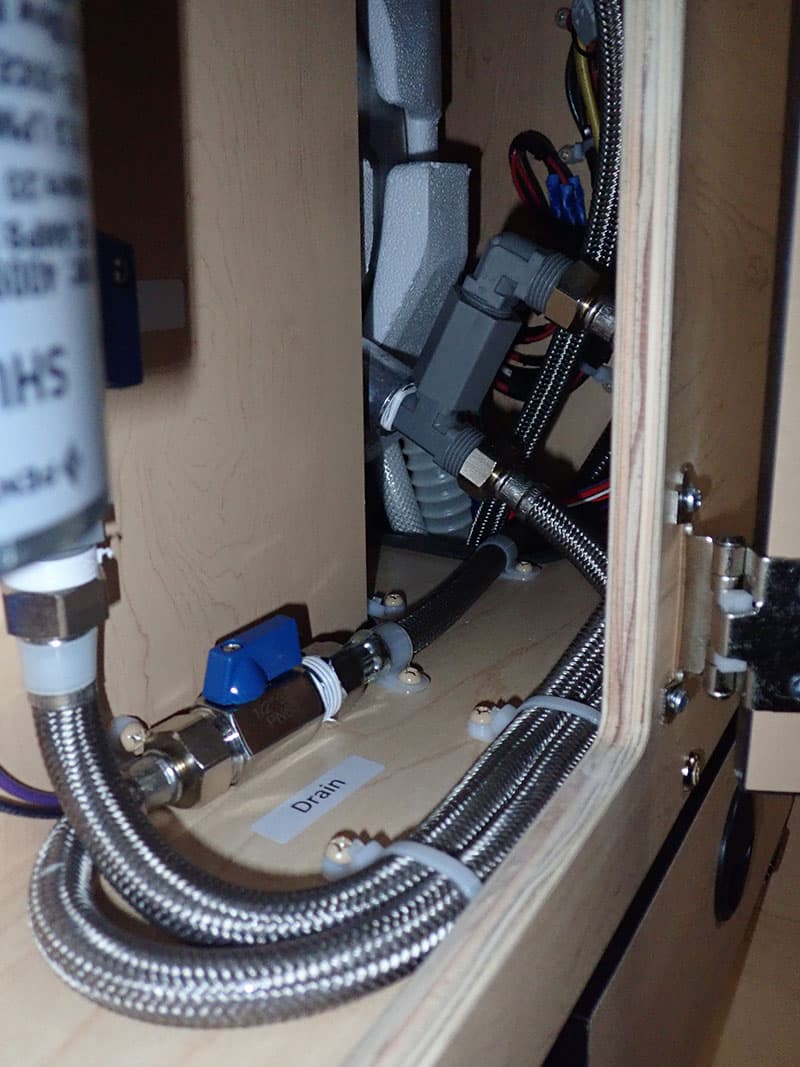

Above: The plumbing manifold with the polymer braided lines

TCM: For 2018, Four Wheel Campers is changing from PEX plumbing lines to polymer braided plumbing lines. PEX is used almost universally throughout the greater truck camper and RV industry. Why is Four Wheel Campers getting away from PEX?

Stan: Two reasons. One, the polymer braided plumbing lines are more efficient for manufacturing. They are not any cheaper. In fact, they actually cost more money. The polymer braided plumbing lines are also more efficient on the production line.

Another three to four hours of production time has been cut because of the polymer braided plumbing lines. We literally went from about fifty PEX connections to approximately eight with the polymer braided lines and manifold. Each of those fifty PEX connections was a potential leak, so the benefits to the consumer are incredible. More importantly, the polymer braided plumbing connections can be hand tightened. PEX lines and connections were often much harder to access for repair.

With the plumbing manifold, the plumbing system is all hooked up to one distribution point. Any customer can work on it. We leak and pressure test the entire plumbing system before it leaves the factory.

Dan: We changed to the new propane and plumbing systems in late August of 2017. So far, there have been no issues or customer complaints about these systems.

Above: Winterizing is still necessary with the new plumbing lines

TCM: Are polymer braided lines less susceptible to freezing and bursting?

Stan: You still have to winterize the camper. The water heater tank, the water pump, or the manifold could freeze and crack if it’s full of water and freezes. With a Philips screwdriver, you can take the manifold off and change the lines. The new lines are similar to a fitting on a garden hose. The real customer benefit is that the new propane lines are more flexible and easier to repair in the field.

Above: The polymer braided plumbing lines are more flexible

TCM: In the email describing the 2018 updates, the new plumbing was described as “cleaned up”. What does this mean?

Stan: The old PEX plumbing system had a lot of twists and bends. It looked like a spider web. The new polymer braided plumbing lines and manifold plumbing system is more simple. We went from five elbows and crimped-on connections to zero. It’s a big difference.

Dan: The braided lines and manifold plumbing system also allows us to make improvements to our cabinetry. Flexible hosing easily goes around things. The hard start and stop PEX lines were very restricting. More importantly, if a customer needs to find or repair a leak, they can find it, understand it, and make a correction.

We have also improved how we test our plumbing system. We used to test the water lines by pushing water through. Now air goes through the lines which gives us a much higher tolerance for testing. We can see leaks and other problems better. These are the kinds of little things that add up with our improved production efficiencies and quality control.

Above: The Bat 270 awning is a new option for 2018

TCM: Tell us about the new Bat 270 awning option.

Stan: It’s a high-quality 270-degree awning. Air shipped from South Africa, the Bat 270 is an expensive option at $1,750, but it offers a lot of rear and side coverage.

We also offer a standard 8-foot side awning.

Above: The Overland Solar 160-watt panel

TCM: The solar panel and controller options have also changed for 2018. Tell us about the new Overland Solar 160-watt panels and MPPT controller.

Stan: We were using Zamp solar panels and controllers, but the Overland Solar 160-watt panel and MPPT controller is of much higher quality. Overland Solar’s technology is better and offers improved output with a lighter weight.

Above: Overland Solar MPPT controller

We have tested the system for months both in the sun, in the shade, and inside the building. The output is better in every aspect; especially when part of the panel is shaded. We also dropped 12 to 15 pounds of weight off the roof. With a pop-up camper that has a manual roof lift, roof weight is important.

TCM: Speaking of roof lifts, will Four Wheel Campers ever offer an electric roof lift?

Stan: I would say no, but I never say never. Four Wheel Camper’s manual roof lift is more reliable and durable than any other lift system; manual or electric. If you have cables in the walls and electric motors, you are dead in the water if something breaks.

We have offered a manual push-up roof since 1972. The lift panels have gone from wood to composite for weight reduction, strength, and longevity. A Four Wheel Camper lift mechanism is never going to wear out.

Dan: Our engineering team is looking into ways to make the roof easier to lift. The gas struts certainly help, but we are always looking for ways to make it easier.

TCM: The gas struts make a huge difference. Before we move on, what does the Overland Solar 160-watt panel and MPPT controller cost?

Stan: The solar option costs $1,050. The Zamp solar system without the MPPT was $995.

The Overland Solar 160-watt panel is a solid flexible panel. Overland Solar put a backing on the panel for us so that we can raise it off the roof. We use our normal Z-bar, which is an aluminum solar bracket to keep it off the roof. If you glue a flexible solar panel to the roof it will degrade really fast in the heat. Solar panels need to breathe.

Dan: Stan mentioned this earlier, but it warrants repeating; the Zamp panels would output zero power if they had any amount of shade on them. The new Overland Solar panels are wired with individual solar zones that continue to charge even if part of the panel is shaded.

Above: 6-volt AGM batteries are optional

TCM: Four Wheel Campers is now offering 6-volt AGM batteries as optional. Why might a customer prefer 6-volt versus 12-volt batteries for a Four Wheel Camper?

Stan: The 6-volt AGM batteries we install have approximately 25-percent more amp hours than the standard 12-volt Group 27 AGM batteries. Two 6-volt batteries give you 225 amp hours versus a 12-volt at 150 amp hours. That’s significantly more power.

Above: For the 5S system, everything is organized, labeled, cleaned and accounted for

TCM: Four Wheel Campers is currently implementing a 5S and lean manufacturing system. Can you explain what the 5S system is, and how you’re implementing it?

Dan: Toyota was one of the early adopters in the 1960s of the 5S system. It’s is a building block to becoming a world-class manufacturer. 5S gets rid of everything in the plant or office that we don’t use on a daily or hourly basis. You organize what’s left in a fashion that’s very visual.

We will get rid of closet doors and label everything. We will standardize equipment and organization across the factory. That way if employees go from one area to another, there is a familiarity to the look and feel. They don’t have to relearn where a hammer is located.

In January we started a formal 5S program with Sacramento State University. They are training 22 people in our company; 18 in the plant, and 4 in the office. For ten Wednesdays in a row, the Sacramento State University instructors trained our team for three hours.

To implement the changes, we shut down our plant for an entire Monday and half day Tuesday for a Kaizen (continuous improvement) event. Everyone did a project to improve our processes for each team and department. Then the eleven team leaders gave a five to ten-minute presentation to explain their results.

With consulting, training, and downtime, 5S will be a $55,000 investment. That’s 10 weeks times 22 people and 1.5 days of not producing campers. That’s how much we believe in improved production efficiency and quality control.

After the 5S training and implementation, we need to sustain it. We will audit the teams every day. One person in each department goes through a checklist every evening. Everything has to be in the same spot as when they walked in that morning.

Each month the audit team goes through our whole organization with a list looking for disorganization, things that aren’t clean, things that aren’t documented, and then formally reports back to the staff. The team leaders get the list of the problems and have to get them fixed within a certain time period, which is usually five working days.

TCM: That sounds intense. How has the 5S team been received by the production and office teams?

Dan: The Four Wheel Camper team is excited. They are giving their opinions and get to participate in a college-level class. Everyone gets involved. Everyone owns their area. Everyone is respected. Everyone has a voice. If there is a problem, we identify it as a process problem – not as a people problem.

Above: New signs on the exterior of the Four Wheel Camper building

TCM: Since the Salt Creek Capital acquisition in 2016, Four Wheel Campers headquarters has undergone something of a physical transformation. Talk to us about the plant changes.

Dan: We want the entire experience of visiting Four Wheel Campers to be positive; from the moment they pull up to the factory to when they leave with their new camper. We want them to feel confident about Four Wheel Campers because they are buying an expensive product.

Above: The customer waiting area at Four Wheel Campers

Stan: We have new exterior and interior signage, new landscaping, and new furniture. We are tying our presentation and image to match the product we sell.

Dan: We also want to reduce stress with our employees, which is an output of 5S. It’s the management’s job to give everyone the best environment and tools that are economically possible. We are trying to make the workplace visually better for the employee and customer.

The sixth S of 5S is safety. We’ve introduced new cutting tools and eye wear. Eye wear went from $.70 to $8.00 a person. It’s a huge investment, but it’s important. We also gave everyone a back brace that fits their bodies and new gloves. We are trying to improve everything from aesthetics to safety.

TCM: You also described resetting the factory. What does resetting the factory mean?

Dan: We did spaghetti diagrams of how our team moved throughout the factory. It was incredible how much people walked all over the place. There was a lot of crossover between production areas.

Any build component and the tools to build it are now in as close proximity as possible to the person doing the work. The order of events and the distance of the order of events must be minimized.

The big change is going from taking raw materials off shelves as the camper is going down the line to pre-staging those raw materials on a mobile cart. If you come here in a year you will see carts with a job tickets. The ticket will have every component for each camper printed on it. As it’s put on the cart, there will be yellow highlights on the list. All of this pre-staging will be done two to three weeks before a camper hits the production line. If anything is missing we will know two weeks in advance.

Production should not be spent pulling things. Right now production departments are pulling their own materials. We want all raw materials delivered.

Above: Multicam CNC router for cabinets, doors, and facing

TCM: One of the new pieces of equipment is a Multicam CNC router. What are you using this CNC router for?

Dan: We have brought our cabinetry production in-house to reduce costs and to open new design possibilities. The engineering department can send a file to the Multicam CNC router and, in ten minutes, get a result to test. They now have instantaneous control. To encourage more innovation, the engineering team can do what they want on the CNC router every Friday after 3:30pm.

Stan: With the new CNC router, our cabinets, doors, and facing are all perfectly lined up. The fit is much tighter giving the cabinets a crisper finish.

TCM: Are you looking to purchase and implement more CNC equipment in the future?

Dan: We are looking into a CNC machine that will cut all of our fabric. It will be a digitally driven CNC for fabric for the upholstery department. Fabric cutting is currently done by hand. That’s our next automated step.

TCM: Are Four Wheel Camper prices increasing for 2018?

Dan: The price increase happens in November. From 2017 to 2018 we increased prices by about 6-percent.

TCM: One of your stated goals after the acquisition was to increase production and quality. Do you believe you’ve been able to achieve these goals, or are they still in the works?

Stan: Pretty much everything in this interview from the better equipment, to CNC, to the 5S system, and the new water lines, propane lines, and electrical, have all increased production and quality. Four Wheel Campers has made tremendous improvements in production and quality since the acquisition.

To visit the Four Wheel website, go to fourwheelcampers.com. Click here for a free Four Wheel brochure.