Truck Camper Magazine talks with Mike Hallmark, Marketing and International Sales Manager for Hellwig Products, about helper springs for truck camper rigs. Is your rig under or over-sprung?

In an ideal world, a properly payload-matched truck and camper would sit level and drive with confidence. That’s why you read, “How To Match A Truck and Camper“, followed the steps, made the required calculations, and assembled the resulting payload matched truck and camper – right?

Well, not exactly. In reality, even properly payload-matched truck and camper rigs often need a little support to balance and distribute the load. It’s actually quite rare that a truck and camper doesn’t need a little after-market suspension support to eliminate sag, level the rig, and control sway. Of the three carefully payload-planned, calculated, and assembled rigs we’ve owned, all three have needed suspension enhancements.

There are many products and paths toward achieving this goal; bump stops, air bags, shocks, sway bars, and helper springs being the most popular. From this list, helper springs probably garner the least amount of attention within the truck camper market. Some of this oversight belongs here in the electrons of Truck Camper Magazine. We too have taken helper springs for granted. That ends now.

For a deep dive into the helper springs category, we contacted Mike Hallmark, Marketing Manager and International Sales Manager for Hellwig Products. Not only is Mike a die-hard automotive enthusiast and expert, but he’s also a fellow truck camper owner and outdoor addict. And this guy isn’t exactly sneaking around with his truck camper rig either. He purchased the 2016 SEMA Lance-Hellwig rig; aka The Rule Breaker. Try pulling that black and yellow beast of a machine into a fuel station and not talking to everyone. Not happening.

The following interview should be considered required reading for all current and future truck camper owners. Mike not only details the basics of helper springs and their truck camper application but discusses the pitfalls many of us fall into with aftermarket suspension. Have you added too few or too many suspension products to your rig? Are you under or over sprung? I know we’ve gone down that road a time or two. Let’s dig in.

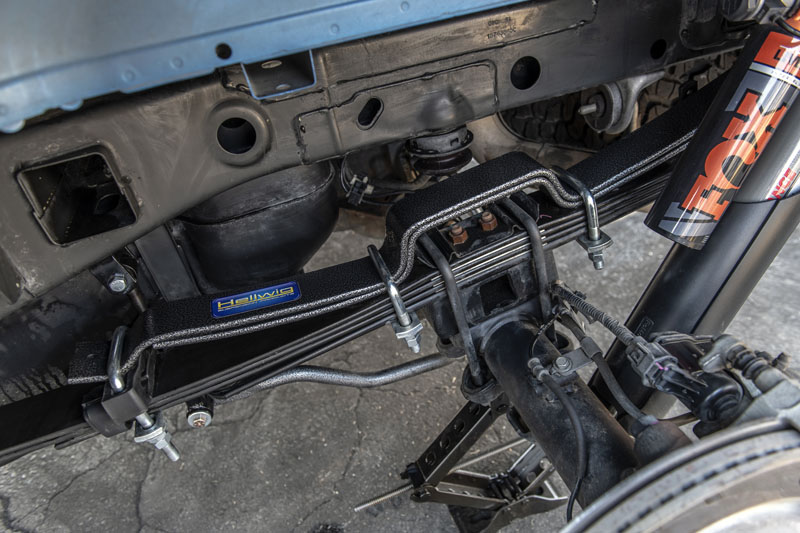

Above: A Hellwig Products helper spring installed on a OEM spring pack

Let’s start with the basics. What are helper springs?

The most basic description of a helper spring is a single or multi-leaf set of arc-shaped rectangular steel with adjustable mounting points at both ends that attach to a truck’s OEM spring pack. Once installed, helper springs do as their name implies, they help the OEM spring pack support the loaded weight of a truck.

Since 1946, Hellwig has had a “no saggy bottoms” policy. This refers to the rear sag or drop that can happen when weight or a load is added to a vehicle. The reduced ride height in the rear impacts the ride quality, overall handling, performance, and safety of a vehicle.

For many truck owners, helper springs are a simple and cost-effective solution to regain the factory-designed ride height of a truck.

Above: The above Hellwig Products video explains how helper springs work

How do you determine if a loaded truck is at proper ride height?

There’s an easy visual aid. Start with your unloaded truck and measure the center line of a rear wheel (or a fixed point on the rear wheel) to the top of the wheel well. Then load your camper and repeat the measurement.

If your truck sags or squats more than 2-inches (roughly), the proper ride height is compromised and you should consider a load support solution.

What if the truck sags more than 2-inches under load?

The same advice applies. If the rear of your truck is lower than level ride height, your front traction is decreased. As a result, the steering will be less responsive while driving due to the improper distribution of weight from the front to the rear of the truck.

Evenly distributing the weight will result in a more comfortable driving experience and give you confidence that you’re in control of the vehicle. Nobody wants to drive a vehicle under a load that feels uncomfortable and unsafe. I’m not a fan of white knuckles.

Above: The above Hellwig Products video goes through a helper spring installation process

How are helper springs installed in a truck?

The factory suspension in your truck determines the style of helper spring that needs to be installed, and how it’s installed.

For example, the Ford Ranger helper springs feature two U-bolts forward and back and a cradle that holds it in position. For this application, you don’t even need to remove the wheels from the vehicle to install the helper springs.

Some truck makes and models require the truck to be properly jacked and the wheels removed to access the OEM spring pack. That said, all of the helper springs Hellwig manufactures are designed to be installed in your driveway with a ratchet wrench and simple hand tools. Power tools can speed the process, but they’re not necessary.

In broad terms, you begin by parking your vehicle, chocking the tires, and allowing the exhaust system to cool. If your particular truck make and model requires it, or if you prefer easier access to your OEM spring pack, properly jack up the vehicle and remove the rear wheels.

Some helper springs have the same design forward and back and some are asymmetrical. Following the included instructions, orient the helper spring and mount it in the center (over the axle) of the OEM spring pack. Once the helper spring is in the right position, bolt it down with the provided parts. Be sure to follow the instructions for proper torque and tension.

The next step is to lower the vehicle, remove the chocks, load the camper, and drive it for ten to fifteen miles. After the drive, you can adjust the helper spring tension to provide more or less support. We have several helper spring installation videos on the Hellwig Products website or YouTube channel showing the process and adjustments.

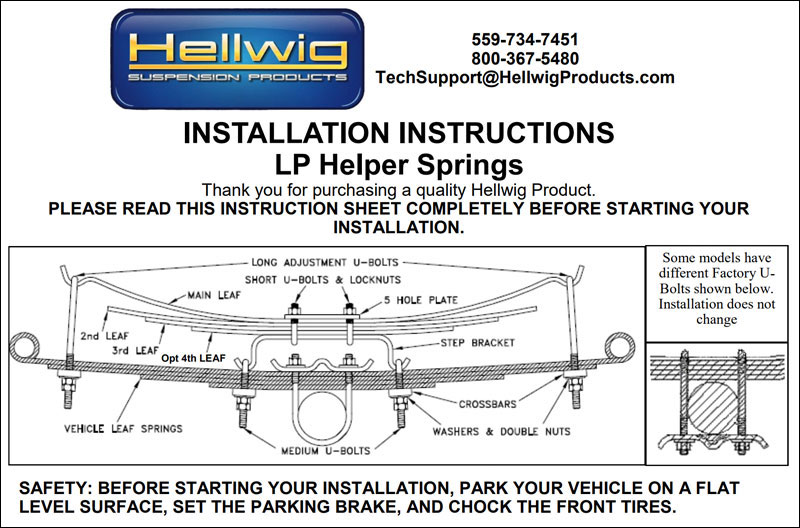

Above: An excerpt from the instructions for the Hellwig Products LP Helper Springs

Are the provided instructions specific to the truck’s make and model?

Yes. The instructions are specific to your make and model. They have both text and images and point out the key things to look out for during the installation. If there are any areas of concern during installation, we illustrate that in a picture and point it out in the written instructions.

What if someone needs additional help during an installation?

Call and talk to a Hellwig Technician at 800-367-5480. Our techs are available Monday through Friday. A live person answers the phone. If you run into an issue on a Saturday or Sunday, you can go to our website or YouTube channel to see if we have an install video for your vehicle. Sometimes there is overlap with other vehicles if we don’t have a video for your specific truck.

Are helper springs applicable to all pickup trucks?

Hellwig has helper springs for US domestic vehicles going back to the mid-1960s. We go from smaller platform Toyotas all the way up to one-ton trucks and beyond. Anything that has a rear leaf spring, odds are we have an application. For trucks like the Ram 2500s and 3500s with the coil rear springs, we don’t have a solution. If it has a leaf spring, we should have a solution for you.

Are there applications where a helper spring doesn’t make sense?

Yes. Unless the back end of your truck has a compromised ride height, you are wasting your time and money with a helper spring. You can also harm your driving performance if you add a helper spring to a truck that doesn’t need it.

It’s not unusual for truck camper owners to tell me that they have helper springs, bump stops, and air bags, and bigger shocks but their rig drives horribly. One look at their set-up reveals that their truck sits higher than stock. This is a tell-tale sign that a vehicle is over sprung.

In this situation, I recommend removing the aftermarket suspension products to restore the proper ride height. If you have too high of a spring rate, you will have a rough ride. An over sprung truck and camper rig could also promote porpoising. This is when a rig bounces forward and back while driving.

Above: Hellwig LP 25 Helper Springs

Beyond the specific truck make and model fitment, Hellwig Products offers a range of helper springs. How does someone know which helper spring to get?

That depends on the weight you’re looking to load into your truck. It also depends on the current payload of your truck, and what your current springs are rated for.

Going back to your questions about how you determine if you need a helper spring, if your camper stops at level under load, you don’t need a helper spring. If it drops below level, consider one of our Pro series or an LP25. If you have a 4,000 to 5,000-pound truck camper (wet and loaded), our LP35 is likely better suited.

For more specific advice on which helper spring to select, call our factory or go to the dealer locator page on our website. We also have a FAQ page that addresses common questions.

What if a person gets the wrong one?

This is why it’s important to call our factory or an authorized Hellwig Products dealer. They will steer you to the right product.

Once a product is installed, we cannot take it back as a return. Once they are installed, our steel products come with a limited lifetime warranty. If there is an issue, Hellwig will get it taken care of in a timely fashion.

For anyone who has questions, always contact us before making a purchase. The best tool in your toolbox is knowledge. There are plenty of online forums, our website, our tech support, our videos, and our dealers.

Do helper springs increase the GVWR or payload capacity of a truck?

Not one bit. We never recommend going over the GVWR of your vehicle.

There is more to your suspension than springs including your axles, brakes, tires, and front suspension. There are many critical factors taken into account when manufacturers rate the payload of their trucks.

By going over payload, you are compromising the load on the bearings, how the brakes stop the vehicle in an emergency situation and handling while you are steering. Always stay within the GVWR range.

If you’ve already bought a camper, figure out the payload you need. Then, whatever truck you want, get the size bigger. The money you spend on that vehicle will be offset in aftermarket support products to offset that load.

Above: An installed Hellwig Products Big Wig rear sway bar

Are helper springs designed to work in conjunction with other suspension enhancement products; bump stops, sway bars, air bags, and shocks?

The majority of suspension products are complimentary to the entire suspension package. Specifically, our helper springs are designed to be complimentary to shocks and rear sway bars.

When it comes to other load support products, find one solution and stick with it. Find the solution that works best for you to have a level ride height.

I always recommend truck owners fix the problems they experience. If you have excessive body roll and sway, add a rear sway bar. If you have rear sag, add a helper spring. Avoid installing a product that solves a problem you don’t have.

Above: Mike Hallmark’s truck camper rig – The Rule Breaker

How would you approach a truck camper set up?

Lucky for you, we’ve done it a few times with the Rule Breaker and Altimeter SEMA rigs with Lance Campers.

Figure out what camper you want first and calculate the loaded and wet weight. Camper manufacturers list the dry weight, which is often the camper without options, water, propane, or your stuff. Make sure to calculate the most accurate loaded and wet weight possible before proceeding. Find that number.

From there, find the truck platform that is best for that load application. Once you have a truck with the appropriate GVWR, load the camper and fix the suspension problems (if any) you experience.

The different manufacturers, GM, Ford, Ram, Toyota, and Nissan, use their own specific styles of springs. Get the camper on your vehicle and see how it sits. If the ride height is compromised, start there. If the rig has sway, add or upgrade the sway bar to a larger diameter Hellwig sway bar.

Above: EZ-550 helper springs

Upgraded sway bars have made a huge difference on our truck camper rigs. Getting back to the helper springs, how much weight do they add to a truck?

It depends on the springs you go with. Our smallest EZ-550 helper spring is under 10 pounds per side. At the other end of the spectrum, our LP35 is about 55 pounds per side.

How much do helper springs cost?

Our least expensive helper spring kit is the EZ550 at $105. Our most expensive helper spring kit is the LP-35 at about $800. The kits include both sides of your rear axle and everything you need to install the helper springs.

In some situations, would it make more sense to replace the OEM truck springs?

Unfortunately, yes. If an OEM spring pack has been compromised, it needs to be replaced. For example, if you live in a humid environment with salt and you get a build-up of rust or if the leaf packs rub together, you should consider replacing the OEM spring pack.

How do helper springs affect ride quality when the camper is not loaded?

It depends on the category of helper spring you get. Typically you are not going to see an unladen ride quality change with smaller helper springs. The LP25 and LP35 are multi-leaf packs so, depending on tension, you may see a change in unladen ride quality with those products.

One solution to improving the loaded and unloaded ride quality and comfort is to upgrade your shocks. Shocks are designed to reduce undulations or the up-and-down bounce of your truck. When you hit a bump, the shocks’ job is to bring the truck back to ride height within one cycle of the truck going up and down. If you hit a bump and it keeps bouncing, you don’t have enough shock for the spring rate of your vehicle. You need to get a better shock to match your spring rate to mass.

We’ve talked a lot about helper springs but we haven’t discussed wheels and tires. How do you address wheels and tires in conjunction with a truck’s suspension system?

Wheels and tires are of the utmost importance. Your wheel and tire combination is an active part of your suspension. Your tire takes lots of weight with a truck camper, so always check its load range rating. Tires come in a variety of ratings typically called out by an Alpha rating (A, B, C, D, E, F…). Make sure that you are running a tire rating that can carry the weight of your loaded and wet camper or you will get side wall wash and wiggle.

What do you mean by wiggle?

If your tires are not rated for the weight you’re carrying, the tire can bulge because it does not have the infrastructure to carry that weight. While driving, this will move the tire left to right as the sidewall bulges. It can feel like you’re driving on soft mud because the back of the truck will wiggle on you.

Another problem that can happen is an underrated wheel itself can fail due to stress. The weight can come up the outer rim of the wheel and magnify in the center part of the wheel. I have physically seen this happen because the wheel is not rated for the vehicle it is carrying.

If you have low-profile tires, you typically experience a rougher ride since the tire has less of a side wall. If you go with bigger tires, like a 40-inch tire and 17 or 18-inch wheels, there is a lot of flex on the side wall. The message with all of this is to make sure you are running wheels and tires that are rated for the weight that you’re carrying.

Above: Hellwig contact helper springs

That is very important advice. Is there anything else you want truck camper owners to know about helper springs?

One thing I didn’t touch on is our contact helper springs. Anyone with a one-ton truck with factory contact overload springs might find them helpful.

Contact helper springs are mounted on top of the OEM spring pack and deaden into the air. Once the contact helper spring comes into contact, it displaces the load and increases the spring rate. For a one-ton, this is a low-cost item to address your ride height.

Finally, I want to repeat my advice about buying the product that will solve the problem you’re having. Too many truck camper set-ups are either under or over sprung. A load support product will get your proper load height for optimal handling and comfort. If you have questions, we are here to help.

For more information on Hellwig’s helper springs, visit their website at hellwigproducts.com. Click here to request a free Hellwig brochure.