Truck Camper Magazine visits Rugged Mountain RV in Emmett, Idaho to see first hand how the biggest flatbed triple-slide and non-slide truck campers on the planet are made. Back up the Class 5 truck!

Whenever we publish something on Rugged Mountain, people go nuts. And it’s not just their enormous, flatbed triple-slide and non-slide floor plans that get people excited. Oh no. It’s their audacious tiny home interiors, determined blend of old school and modern materials, and their steadfast, not even going to debate it, Class 5 truck requirement for their flatbed models. See? Some folks are already running hot and heavy to the comment section. Happens every time.

Now that some of us have left the building, let’s set a few records straight. First, Rugged Mountain also builds a fantastic line of hard side non-slide slide-in truck campers that can absolutely payload match one-ton dually pickups. Our own personal camper has nearly the same floor plan as Rugged Mountain’s Granite 11RL. Can the 11RL payload match with a one-ton dually? Yes! If you love Rugged Mountain but don’t want a Class 5 flatbed beast, they have a camper for you.

Like all RMRV campers, the 11RL is wood-framed with spray foam insulation and high-gloss Crane Composite fiberglass walls. And there goes another wild round of social media comments. “Did he say wood-framed?”

Yes, I did. Tempting as it may be to tiptoe around this topic, I can tell you with absolute certainty that Rugged Mountain’s Chief Visionary and CEO, Jesse Collinsworth, would rather tackle that subject straight on.

Hang tight, Jesse. We’ll get there.

When we first visited Rugged Mountain RV in 2017, they were in a large modern building in Nampa, Idaho. The facility presented well from the outside, looked the factory part on the inside, and was convenient to I-84 and Boise.

Unfortunately, it was also prohibitively expensive and becoming more so. As it was explained to us, their first location was consuming the resources they needed to innovate and grow the company. That’s when Rugged Mountain moved to an old Boise Cascade paper mill about forty-five minutes away in Emmett.

And here’s where you need to remember that old adage, ‘Don’t judge a truck camper manufacturer by the outside of their factory’. Rugged Mountain’s new location looks like it was built sometime during the Roosevelt Administration—the first one. But inside, it’s perfect for what Rugged Mountain needs.

Stepping into the facility, you’re presented with a huge, bright, wide open space that would be the envy of many a camper company. The funny part is that they’re not just running one manufacturing business out of this colossal space, but two.

About half the factory is dedicated to Rugged Mountain RV building truck campers. The other half is dedicated to their first company, Tiny Idahomes.

Above: This freshly completed Tiny Idahome was immediately outside the factory

You can’t truly understand Rugged Mountain RV, their campers, and interiors until you’ve seen the ‘tiny homes from Tiny Idahomes’ (say that three times fast). Over the years, Angela and I have explored at least half a dozen Tiny Idahomes at the factory, and every time our conversation is the same…

They’re gorgeous! We could totally live in one!

Angela starts talking about which area would be her sewing room, where my stereo system and records would go, and how Cosmo would love the different levels and stairs to jump around. Then we go back into the factory and remember we’re covering truck campers. This. Happens. Every. Time.

As big as the Rugged Mountain RV factory is, it fills up fast with three Denali 3S triple-slide flatbed truck campers on the line. For the record, these are the largest demountable truck campers on the planet.

These flatbed beasts require the capabilities of a Class 5 truck. Before you think that’s a big deal, the Rugged Mountain team puts Class 5 flatbed rigs together all the time. To them, a Class 5 flatbed truck with a triple-slide flatbed camper is just another Tuesday.

The photograph above shows the second half of the line. Here, the basements are completed, then the walls are installed, and then final finishing adds the wrap, seals the campers tight, completes the interior, and adds the features and options selected by the customer.

Above: Gary lays out a Rugged Mountain flatbed sidewall frame

And here we go! Jesse Collinsworth, CEO of Rugged Mountain RV, is a huge and unapologetic proponent of wood framing for truck camper construction. He’s well aware that wood framing flies in the face of an industry that has largely moved to aluminum framing, composites, and lamination. He is routinely asked why he’s so steadfast about his choice of wood, and always gives the same answer.

Here’s how that goes down. First, he smiles. Then he explains that wood bonds more reliably than aluminum, preventing the delamination issues he has observed in Idaho’s extreme hot and cold temperatures. Next, he says wood also avoids the heat and cold conductivity and condensation problems of aluminum, and provides significantly better fastener strength. And while some worry about rot, Jesse considers delamination a far greater and faster-developing threat. Then he looks at you, still smiling, and waits for your response.

Above: Gary and Rob trim and complete a Rugged Mountain flatbed sidewall frame

In truth, there are real pros and cons to every way of manufacturing a truck camper. Wood gets a bad rap because so many companies have moved on to aluminum, composites, and lamination, and enjoy taking shots at the old wood block. They have their valid points, but so does Jesse.

Our point would be to understand the specific pros and cons of the different materials campers are made from, and take responsibility to maintain your camper accordingly. If you buy a wood-framed camper and properly inspect and maintain your roof, side, and underbody seals on a twice-a-year (spring and fall) basis, you’ll have a camper that lasts a lifetime. Skip that maintenance, and you could be in trouble. Of course, that goes for every camper, no matter what materials or manufacturing processes are used.

Above: Jake operates the CNC machine

About two years ago, Jesse took the plunge and brought a CNC machine into the plant. From experience with multiple truck camper companies, we know that bringing a CNC machine into a truck camper factory is a bit like taking the red pill in The Matrix.

Once the CNC machine lands, everything changes; not just the accuracy and repeatability of the material cuts, not just the design of the campers, but the fundamental way the company approaches design and manufacturing. CNC isn’t just another tool. It’s a revolution.

In the hands of someone like Jesse, CNC can lead to sleeping in the factory, followed by a group of friends and family gathered around for an important conversation. I kid, but listening to Jesse talk about how excited he is about his CAD machine (and the CAD that runs it) reminds me of how I felt foisting an Atari 2600 above my head Christmas morning 1980. I still love that thing!

Now, some company owners would let their production team take over a new and relatively complicated tool like this, or hire an expert. Not Jesse. He doesn’t believe in having any tool or process in his factory that he hasn’t himself mastered. And the CNC machine and CAD was, at that moment, outside of his comfort zone.

You can probably guess what happened next. By his own admission, he became obsessed with this new machine, spending all hours of the day and night learning exactly how it worked, what it was capable of, and developing the CAD programming necessary to CNC cut cabinetry and other critical components for Rugged Mountain RV and Tiny Idahomes. The revolution had begun.

And yet, there’s still a lot of old school, time-tested and proven tools and practices going on at Rugged Mountain. Here you see Gary—by far the most experienced truck camper builder in the building, if not the world—hand routing the sidewall he just assembled. In other factories, this process might be done on a big CNC machine, but that hasn’t happened at RMRV, yet.

A word on Gary. This guy has been building campers professionally since he was 14 years old, but says he’s never spent a night in one. Before joining Rugged Mountain, he worked at Northland Campers. Now he helps the team by working anywhere in the factory, except on the things he doesn’t like. You can do that when you’ve got more experience than the next five guys combined.

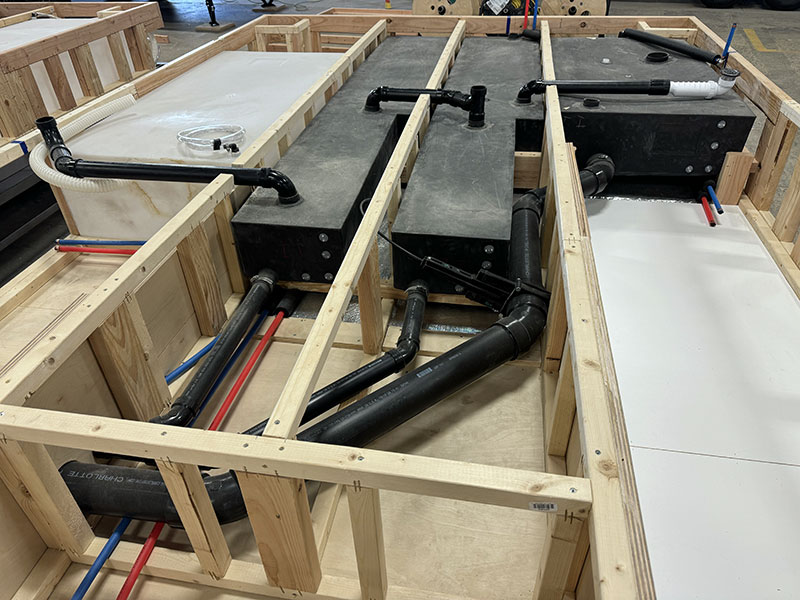

Above: Christian lowers the second of two grey tanks into a flatbed basement

Rugged Mountain flatbed truck campers feature some serious holding tanks; 80 gallons fresh, 77 gallons grey, and 35 gallons black. There are some campers that beat those numbers in the black department, but nothing else has this kind of capacity in fresh or grey. You want big holding tanks? Rugged Mountain is your huckleberry.

So what does that kind of capacity look like? Here you see not one, not two, not three, but four tanks being installed into a basement. The two middle tanks are connected to make one big—no huge—grey tank. These tanks are one more reason why Rugged Mountain flatbeds don’t mess around with one tons. Would you like a Ford F-550, Ram 5500, or Chevy Silverado 5500HD?

One Rugged Mountain process we were hoping to witness was the open-cell polyurethane spray foam insulation. Unfortunately, our timing was off for this process. What we did see were two camper slide-outs that already had the spray-foam insulation installed.

As the name implies, open-cell polyurethane foam is literally sprayed onto wall cavities using a specialized gun. The foam instantly expands to completely fill the space, cures over a 24 hour period, and is then trimmed with a saw or knife, creating a flat surface. Rugged Mountain states that their insulation is air-tight, provides an excellent sound barrier, and even adds to the structural rigidity of their campers.

We were able to watch the final stages of a Denali 3S basement assembly, including critical details that go into making the interior floor strong, even, and smooth. In the photo above, Alex is installing the slats that support the floor. Note the numerous features that need to be cut into the slats for water lines and tanks.

Once the slats are installed, plywood panels complete the walk-on interior floor structure.

With the plywood panels screwed down, the panels are sanded smooth. This is the beginning of an important process to accommodate the loose-lay linoleum flooring used by Rugged Mountain.

Loose-lay linoleum is a premium product that doesn’t require an adhesive. The heavy weight, thick construction, and rubberized backing create enough friction to hold the flooring in place.

That stated, loose-lay flooring requires the subfloor to be clean, dry and smooth. This means filling in and sanding any floor inconsistencies. The advantage of loose-lay linoleum is that it better accommodates temperature changes, vibration, and expansion. It’s also easier to repair since it’s not glued down.

Elsewhere in the factory, Lee was working on a storage cubby for a Denali 3S center island. Hey, Lee, that’s quite the display of lithium-powered DeWalt tools.

Lithium has impacted more than just camper batteries in our industry. Go back a half-decade and you’d be hard pressed not to find a factory full of air tools of every description; nailers, staplers, drills, screwdrivers, sanders, grinders, caulking guns; you name it. Today, almost all of those tools have been replaced with lithium-powered alternatives. At Rugged Mountain, those lithium-powered tools are DeWalt.

Lee is the electrician on the Rugged Mountain line. This is not an easy position at Rugged Mountain because (a) Jesse can’t help but continuously push the electrical system envelope, and (b) Jesse is an electrician by trade.

I don’t think Lee feels singled out as Jesse could build a Rugged Mountain truck camper or Tiny Idahome himself if left in the factory long enough. From talking to the team, having a boss who understands the process and has the skills to do the work is good, especially considering the alternative.

Jesse is not the kind of CEO who never steps foot in the factory. On the contrary, Jesse was in the factory more often than not observing progress, answering questions, and even working hands-on with the team. Don’t let those fancy sneakers fool you. Jesse loves building stuff.

On one such factory incursion, Jesse showed us the battery compartment in a Denali 3S and told us about the batteries he’s currently recommending: SOK battery model SK12V314PH. Read that model number again and you’ll catch “12” volt, “314” amp hours, of lithium iron “PH” phosphate.

Why does Jesse like these batteries? He explained their well-priced ($999 as of this writing), support Victron CAN Comms, offer Bluetooth function for iOS and Andriod apps, have a self-heating pad, IP67 rating, a robust ABS housing, up to 15,000 cycles, and can be connected in series for 24V, 36V, and 48V banks.

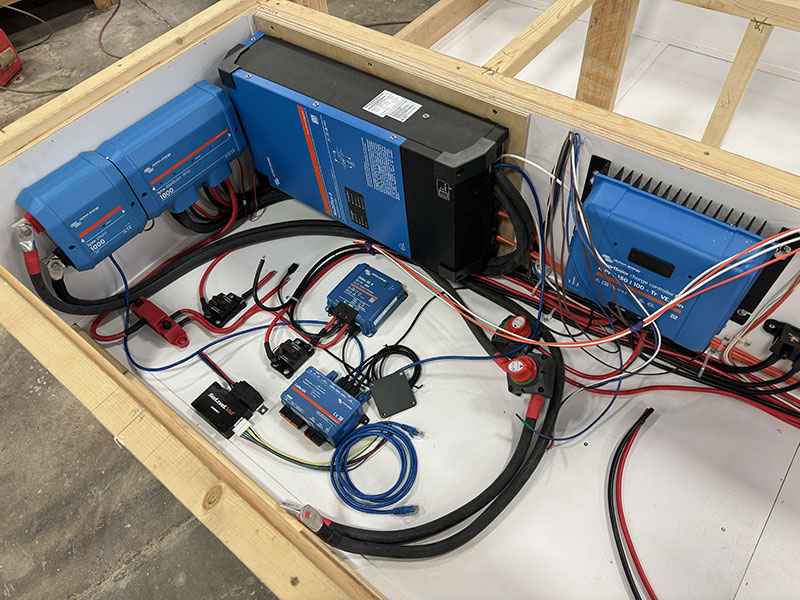

Speaking of Victron CAN Comms, there was a rather advanced electrical system being assembled in a Denali 3S basement during our visit. Rugged Mountain is somewhat obsessed—in the best of ways—with pushing the state-of-the-art in battery, electrical, control, and heating systems. For example, the Rugged Mountain X14 we debuted this past February had 1,350 Ah of lithium, 1,600 watts of solar, and a diesel Timberline 2.0 diesel heat and hot water system.

The pictured Victron system includes a MultiPlus II, MPPT 150|100 solar controller, Lynx 1000 shunt, Lynx 1000 distributor (M10), Orion XS DC-DC battery charger, Cerbo GX, and a SeeLevel Soul.

Jesse explained that advanced Victron systems and huge lithium battery banks are where RMRV customers spend the big bucks to get that coveted “until the Cocoa Puffs run out” off-grid air conditioning capability. That wasn’t exactly how he said it, but you get the idea.

Above: Israel meticulously installs trim in a Denali 3S

I love meeting the production team members and talking to them about what they do and what’s important to know about their process. Over the years, I’ve had some incredible conversations with some amazing people who happen to be building truck campers. Maybe that’s why truck campers are so awesome.

Speaking of amazing conversations, this fella’s name is Israel, and he told me two things that got my attention. First, he said he’s a mathematician. I can honestly say that’s a word I’ve never heard in a truck camper factory before. And second, he has to have everything absolutely perfect—specifically, to 1/32 of an inch. He said it’s from being a mathematician. He actually said it makes him nuts if something isn’t right.

In a Denali 3S, I watched Israel measure the trim, shave the trim, remeasure the trim, shave a bit more of the trim, install the trim, and then measure the trim one more time to be sure. If you’re looking for the best possible fit and finish in a high-end triple-slide truck camper, you want a guy like Israel on the job. I have to admit, his work was impeccable.

We found Jake once more working on final finishing in the Denali 3S at the end of the line. He was installing molding and trim, and generally doing the final finishing detail work that completes a camper before customer pickup.

In this photo, Jake is getting ready to install an electric fireplace in the kitchen island. And you read that last sentence like it was nothing, didn’t you? Because every day I write, “…getting ready to install an electric fireplace in the kitchen island.” I might as well have written, “…aliens landed, vaporized the front office staff, and levitated yours truly and our cat, Cosmo”. Fireplaces and islands in a camper? You remember that’s nuts, right? And kinda totally awesome.

On a slightly more pedestrian plane, Jake then installed a pull-out trash can on heavy-duty steel drawer slides. This is the kind of design touch that happens when you have owners—in this case Jesse and Anca Collinsworth—who actually go truck camping.

In fact, a lot of what you find in a Rugged Mountain truck camper is the result of these two going truck camping with their kids and finding something about their campers they could do better. If you’ve been paying attention, you know what happens if Jesse thinks there’s something he could be doing better. First, he doesn’t sleep until he’s figured out how to make it better. Then he makes it better. Maybe Jesse is a mathematician too.

Dinettes and sofas tend to be installed late in the manufacturing process to avoid said items from being scratched or otherwise damaged in the factory. Once these items are installed, the camper is on its way to a final quality control inspection, and out the door.

Jake brought the rear slide sofa into the camper in pieces and then assembled the sofa in place. This is the kind of process that would be a serious pain in the hindquarters until you know exactly the order to bring things into the camper, how to maneuver those items around without hitting anything, and then the proper approach to putting it all together. Jake got it all done like kids play.

For anyone out there who’s looking at these interior photos and thinking, “show me the finished camper you long-winded monkey,” I say, “It’s Mr. Long-Winded Monkey to you, and check out the numerous photos of the Rugged Mountain Denali 3S triple-slide and the X14 non-slide. Then switch to decaf and reduce your time on social media. It’s bad for you.”

Rugged Mountain is not a high-volume truck camper manufacturer. Where some companies push out two campers a week, or even two or more campers a day, Rugged Mountain completes just a few campers a month. On balance, Rugged Mountain campers are custom (based on set floor plans) and often significantly more complex and definitely bigger than their peers. I honestly think you could fit a few of the smaller hard side campers on the market inside the living space of the Denali 3S and X14.

As a result of their production pace, we were unable to see the entire build process in the two days we were at the factory. That’s not to say that the production team wasn’t dialed-in. They were definitely on the move. And there are some exciting things in development at Rugged Mountain that we can’t wait to break in the near future. Let’s just say that Jesse isn’t getting a lot of sleep right now. There’s something big he’s envisioned, and he has to wrestle it into existence.

Cue the CNC machine.

For more information on Rugged Mountain, visit their website at ruggedmountaincustomrv.com. Click here to get a free Rugged Mountain brochure.