Facing rising demands on production, Adventurer Manufacturing launched the APOC facility to centralize framing, lamination, and CNC routing. The move improved workflow and changed how Adventurer builds campers. Here’s how APOC delivers quality, controlled.

One of the greatest challenges of managing manufacturing growth is how to scale production with the facility, equipment, manpower, and resources available. Optimization can only take you so far. Eventually, investments in nearly every area become necessary to prevent bottlenecks.

Over the years, we have watched Adventurer Manufacturing face this challenge and scale production multiple times. The boldest example was in 2008 when the company moved from Abbotsford, British Columbia to a much larger facility in Yakima, Washington. Since that daring international move, the company has added personnel, embraced 5S lean methodology, added multiple CNC machines, and expanded the Yakima factory footprint.

With the addition of the Scout brand in 2020, the opportunities to scale production within the single Yakima location became increasingly hard to find. If Adventurer Manufacturing was to continue to grow production and improve efficiency, they needed more square footage.

To solve this production constraint, Adventurer Manufacturing launched the APOC building. APOC stands for Adventurer Production Optimization and Control. As you’re about to see, that’s exactly what this facility does.

The APOC building is located in Union Gap, about a ten minute drive from the main Adventurer Manufacturing factory in Yakima. The 31,500 square-foot facility was built in 2019 and has the perfect blend of space: 10,000 square feet of covered outdoor storage, 20,000 square feet of inside manufacturing area, and 1,500 square feet of office. It’s as if the building was built for exactly what Adventurer needed.

The covered outdoor storage warehouses the raw materials needed for framing and lamination.

Above and below: Adventurer Manufacturing uses both wood and aluminum framing materials.

Since the company moved to Yakima, Washington, the company has taken an objective ‘right material for the job’ approach to camper construction. For example, the Adventurer brand line uses both aluminum and wood framing, depending on the model. Eagle Cap is strictly aluminum framing to support multiple slide-outs, and the Scout line utilizes composite panels for strength-to-weight ratio and durability.

All Adventurer Manufacturing truck campers are fully laminated. For that purpose, the entire front of the APOC building is a climate-controlled area dedicated to material acclimation and lamination.

In the photo above, you can see the racked fiberglass rolls and stacked panels. These materials, along with others not shown, will reside in this climate-controlled area for a minimum of twenty-four hours to ensure all materials reach the same temperature prior to lamination.

Using a specialized HVAC and steam humidifier, the material acclimation and lamination area is kept between 75 and 80 degrees Fahrenheit with 50 percent humidity. Walking into this space was quite an adjustment after being in the semi-arid climate outside.

During our visit, the lamination team was laminating panels for the Scout brand. This process starts with CNC-cut and puzzle-shaped composite panels.

To begin the lamination process, panels are put through a roll coater that applies a precise amount of polyurethane reactive hot-melt adhesive to the panels. Once the coated panels are extracted, the adhesive has a specific amount of time before it sets. There’s no taking a nap for this team. It’s go time all the time.

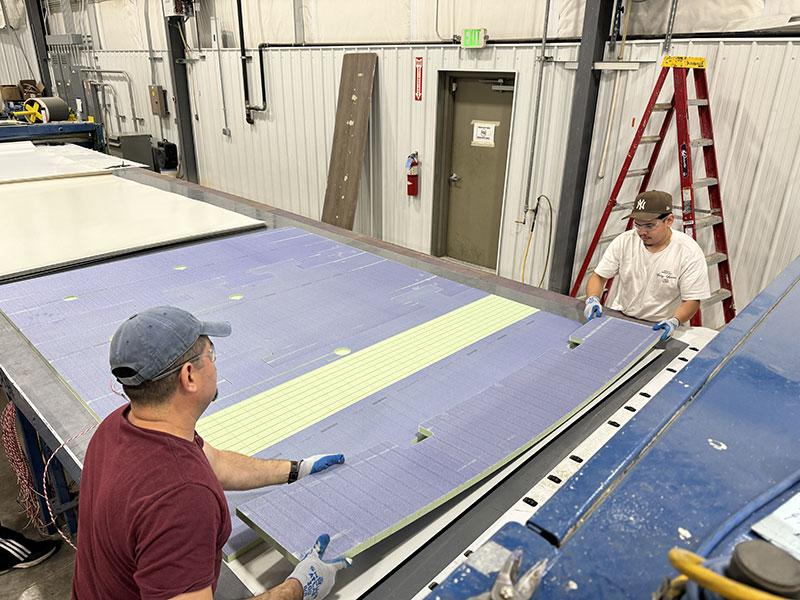

The polyurethane applied by the roll coater is purple, allowing the team to instantly see if the adhesive coating is right. This coverage is vital for the quality and longevity of the resulting lamination.

We often describe campers coming together like puzzles, but the Scout composite sections literally go together like puzzle pieces. The puzzle-like notches guide the lamination team and ensure the composite sections always align perfectly.

Again and again, we saw how Adventurer designed quality and efficiency into the materials and the lamination process itself. In the above image, you can see CNC circular cut-outs and channels for camper wiring. Having the channels pre-cut by a CNC machine dramatically improves lamination-to-lamination consistency and speeds the manufacturing process at a vital moment. Remember, the adhesive clock is ticking.

Once all the composite puzzle pieces are assembled and the wiring has been installed, the gel-coated fiberglass skin is applied. Note that there’s no frame necessary in a Scout composite wall panel.

With the composite wall layers completed, the multiple layers are put through a pinch roller. This machine applies uniform pressure across the entire surface to bond the materials together. Every camper wall made by Adventurer Manufacturing—including Scout, Adventurer, and Eagle Cap—goes through a pinch roll lamination process.

On the opposite side of the room were a half-dozen Adventurer frames getting acclimated for the lamination team. Look closely and you can see the aluminum framing and wood inserts for screw retention.

Immediately outside the material acclimation and lamination room, we found a large C.R. Onsrud CNC machine and a half-ton KUNDEL overhead bridge crane. The overhead bridge crane allows the CNC team to safely lift laminated camper walls and precisely place them onto the C.R. Onsrud CNC machine.

The KUNDEL crane spans nearly the width of the building. This width isn’t necessary for a Scout Tuktut, but comes in handy with a triple-slide Eagle Cap 1165.

The three-axis moving gantry C.R. Onsrud Pro Series is designed to CNC rout wood, aluminum, foam and composite panels, making it the ideal all-around CNC machine for Adventurer Manufacturing.

The pattern for every camper Adventurer Manufacturing manufactures is designed in CAD and then sent to this C.R. Onsrud control panel.

There, the operator can monitor the CNC machine from a safe distance using their eyes and ears. Having talked to a number of CNC operators, they often hear something is wrong long before they can see anything. That’s when they hit the red button before the machine bits and camper parts get damaged.

Laminated and CNC-routed walls are placed on wheeled yellow carts for transport to the main Adventurer factory. There’s something very satisfying about how perfect CNC-cut walls are when stacked together. Note all the pre-cut holes ready for the production line team to install lights and other accessories. More precision. More efficiency. It’s starting to snowball.

All of the laminated and CNC-cut panels are also hand-marked. The panels shown above are destined for Scout Yoho models. The different composite colors—green and yellow—designate different composite densities utilized in different areas of the camper.

Across from the much larger C.R. Onsrud Pro Series is a smaller C.R. Onsrud CNC router cutting Scout cabinetry. And like the other C.R. Onsrud, this router has an operator carefully monitoring the machine.

At the rear of the APOC building is the Biesse Silco SK4 cutting center, added by Adventurer in 2018. Featuring dual blades and synchronized pushing devices, the system moves materials through precisely programmed cutting sequences. The SK4 delivers square cuts, accuracy within hundred-thousandths of an inch, and minimal material waste.

A few feet from the SK4 is where we found the TigerStop TigerSaw, also added by Adventurer in 2018. Cut lists for the TigerSaw are uploaded directly from CAD, after which operators load the material and start the process via touchscreen. The system then measures and executes each cut automatically in seconds, delivering repeatable accuracy.

An automated label printer generates a unique label for every piece of material as it comes off the TigerSaw. Each label includes critical information such as part number, camper model, material type, and dimensions.

The labels create instant identification for internal tracking.

With three Miller welders suspended from the ceiling, the central area of the APOC building is set-up for both wood framing (shown above) and aluminum welding (shown below).

Photos showing the aluminum frames and welding were taken by Adventurer Manufacturing following our visit.

This is the same exact framing area later being used for aluminum frames and welding. Note how they’re welding the aluminum frames in a stack of fifteen for maximum production efficiency.

In this dual-use area, frames for Adventurer (wood and aluminum frames) and Eagle Cap (aluminum frames) are produced in model runs.

Adventurer Manufacturing produces truck campers on two production lines; one for Adventurer and Eagle Cap, and another for Scout. Each production line produces truck campers in runs of ten or more campers of a specific model. This allows the team to set-up and produce batches of frames and walls with increased efficiency. The wall frames shown above are for a run of wood-framed Adventurer 86FB models.

Once the frames are completed, the team inserts closed-cell foam insulation into the frames. This material has been precisely cut and labeled by another APOC team member using a hot wire cutter.

These stacks of wood frames stuffed with closed-cell foam insulation are also destined for a run of Adventurer 86RB truck campers.

To keep the APOC building stocked with materials and deliver the CNC-cut camper walls and components they produce, Adventurer Manufacturing has a dedicated flatbed truck and driver who spends his days between the two facilities. In the photo above, the driver is delivering rolls of gel coat fiberglass camper skin.

Once the fiberglass rolls were unloaded, laminated and CNC-cut Scout walls were loaded for transport. These walls will be driven to the main Adventurer Manufacturing production building, and brought to the Scout production line. On other days, this truck loads and delivers Adventurer and Eagle Cap walls to the corresponding production line.

After visiting the APOC building, we drove the ten minutes to the main Adventurer Manufacturing facility and found these Eagle Cap 1165 walls on their wheeled yellow cradles from the APOC facility. I honestly think you could fit the Scout walls through the Eagle Cap slide-out opening.

Walking the Adventurer production line, we found more evidence of the impact the APOC facility and team are having at Adventurer Manufacturing. First, we discovered more freshly laminated and CNC-cut walls ready to go. And second, we noticed that the factory had been reset to take advantage of the equipment and production areas now housed and utilized at APOC.

While this article is focused on the APOC building, we couldn’t help exploring to see what else had changed on the two main production lines. Or should we say three production lines? For the first time, we noticed two rows of Adventurers going down the line. And everywhere we looked, we saw clean, open space between the stations and equipment.

By moving framing, CNC, and lamination to APOC, and adding 20,000 square feet to the back of the main building (shown above), Adventurer Manufacturing has been able to expand, breathe, and scale production.

Above: The Adventurer Manufacturing APOC team

The APOC team is a proud and tightly knit crew. These guys know exactly what their tasks are and how they fit into the larger process. It’s always a pleasure to observe a focused and highly productive team.

Ideally, APOC would be located on the same campus as the main Adventurer Manufacturing facility, but expansion at that location is simply not possible. This is true for most truck camper manufacturers. Logistical issues, including privately owned adjacent property, prohibitive zoning laws, and environmental regulations, can make expansion unworkable.

The solution of finding a nearby building and optimizing that facility for framing, lamination, and CNC routing has changed the game at Adventurer Manufacturing. Not only does APOC free up the main facility to focus on camper assembly and production, but having a dedicated climate-controlled lamination room improves the quality and longevity of Adventurer’s laminations, and thus every Scout, Adventurer, and Eagle Cap the company makes.

Placing the lamination room, CNC machines, material processing equipment, and framing and welding areas in close proximity further improves efficiency, team communication, and quality across the board. APOC mission accomplished.

Click here to request an Adventurer, Eagle Cap, or Scout brochure.