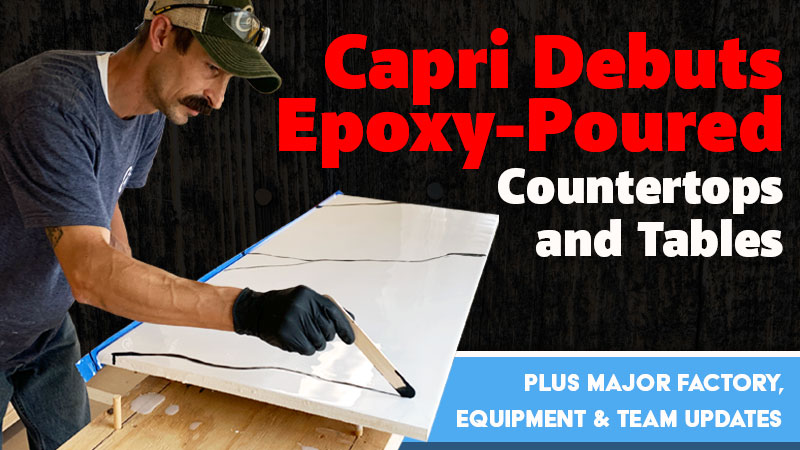

In a truck camper industry first, Capri Campers announces epoxy-poured countertops and tables for 2024. During our visit, we also discovered major factory, equipment, and team updates. Capri is pouring it on.

In 2017, we published an in-depth factory tour showcasing Capri Campers as a time-tested and proven truck camper company. We titled the article, “Texas Time Machine” and celebrated their old-school camper designs, techniques, and overall approach to the marketplace.

Six years later we returned to Bluff Dale, Texas, and discovered the 54-year old company proudly maintaining its status as a classic truck camper manufacturer, but much has changed.

Above: The Capri Camper team in their new facility

Capri Campers has simultaneously expanded and modernized its team, facilities, process, and product to the extent that terms like ‘old-school’ no longer apply. This Texas Time Machine is moving into the future, and fast.

In early 2022, Capri Campers announced their new 100-percent modular Lone Star camper line along with the acquisition of a second facility. The new location allowed Capri to relocate camper finishing, camper delivery, and the main offices. It also gave the original building more space for framing, cabinetry, and inventory.

Above: The new Capri Camper facility, and former Family Dollar store

The facility was a Family Dollar store in its previous life. Looking past its origins, Capri saw essentially a brand new building with 8,400 square feet, tall ceilings, space for a 14-foot door, and good parking. Most importantly, it’s less than a minute from their original location.

Upon our arrival, we were amazed at the bright open space this building offers. The origins of this building may be unusual for the truck camper industry, but the form and function it provides are perfect for Capri production requirements. We can also report that several truck camper companies operate in similarly-sized or smaller facilities, most without a second building.

The new building is air-conditioned, well lit, and provides ample space for camper stations, outlets, tools, and materials. All of this makes completing a camper easier and more comfortable for the Capri team.

The original facility has housed Capri Camper production for decades. Since acquiring the company in 2015, the father and son team, Pete and Tyson D’Acosta, have maximized the building inside and out.

Moving camper finishing, camper delivery and the main offices to the newer facility allowed them to further enhance the original space.

Above: The original Capri Camper facility has been expanded

Out back, they added a covered addition containing well-organized inventory including small parts, air conditioners, propane tanks, Lagun table systems, windows, doors, and trim.

Above: Prepped fresh water tanks await production

Further back they installed an open addition with fiberglass showers and fresh water holding tanks. Since our previous visit, they’ve significantly increased the volume of materials, components, and parts on hand to insulate them from shortages better.

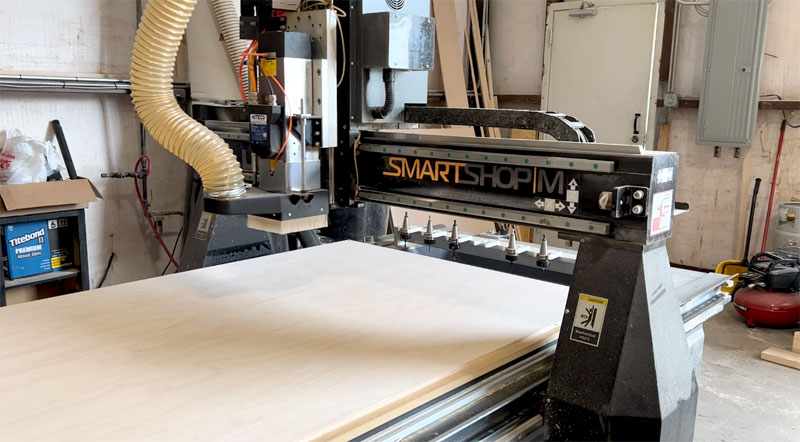

The wood shop, cabinetry shop, and camper production areas now enjoy more work room. This is further evidenced by the addition of a vital new piece of equipment.

Where they once had customer deliveries, Capri Campers has a Laguna Smart Shop CNC machine.

With a 6 HP spindle, 8-position automatic tool changing system, and multi-zone vacuum table, the CNC machine allows Capri to cut materials with greater precision and efficiency than previously possible.

The impact of CNC isn’t hard to find at Capri Campers. Within a few feet of the machine is a rack full of CNC-cut cabinet doors and components (shown below).

Above the exit doors inside Capri Campers is a trim piece with their logo CNC cut into it. As it always seems to do, CNC has found its way into more and more elements improving the design, tolerance, and overall quality of the final product.

Reminiscent of the late Steve Jobs, “One more thing…” moments, Capri had one more thing for us to see. First, they introduced us to their new Operations Manager, Chris Nugent. Beyond being a carpenter, Chris has an exceptional talent for epoxy-poured countertops and tables.

Above: Chris preps CNC cut MDF for the epoxy-pour process

In another example of how the original facility has been repurposed, Chris converted the previous office area into an epoxy pour studio. I’m calling this area a studio because the epoxy pour process is nothing less than production art.

The studio itself was sealed from the rest of the building to prevent sawdust and other contaminants from getting into the epoxy. Chris also built custom jigs to elevate and level the MDF countertops and tables during the epoxy process.

Chris started by painting the MDF countertops and tables white.

He then carefully mixed together the resin, hardener, and coloring.

Next he poured the thick clear liquid onto the MDF forms. By this point, Angela and I were mesmerized.

With the mixed resin and hardener poured across the countertops and tables, Chris spread the liquid evenly across the table surfaces with a large popsicle stick and then gently patted the surface. He explained that the liquid is self-leveling, but needs a little encouragement.

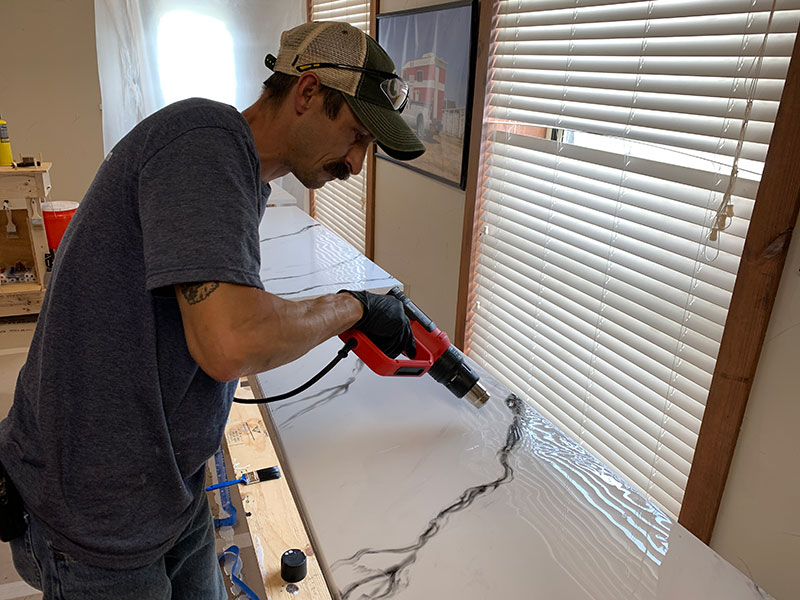

Then things got fired up. With a handheld propane blowtorch, Chris heated the surface to eliminate bubbles and give the epoxy a glass-like finish. Each countertop or table took approximately thirty seconds to blowtorch before proceeding to the next.

Now for the art. With another large popsicle stick, Chris drew shallow lines into the surfaces. From these main lines, he pulled smaller arteries.

These lines were then feathered with a brush, blown with a heat gun, and treated with other ‘secret’ ingredients and processes.

As he scanned his work, he would brush a tabletop here, heat gun a countertop there, and blowtorch a bit on this side or that.

Oh yes, my friends; Chris is most definitely an artist.

We didn’t see the final steps due to the overnight cure time, but Chris explained that the tables and countertops need a bit of sanding, and then a finish coat.

Above: Chris surprised us with a new epoxy-poured dinette table for TCM HQ

What impressed us the most is how the whole epoxy-pour process is production friendly for Capri. Excluding the CNC cutting and prep work, Chris could epoxy pour three to four camper countertops and table sets in under an hour, which is much faster than what the previous laminate and edge banding process took. And the results are in another league.

Above and below: The new table and countertops in 2024 Capri campers

Capri has more exciting news to share in the coming weeks. All we can say for now is that the Retreat is about to advance, and there’s more in store for 2024.

For more information on Capri Campers, visit their website at CapriCamper.com. Click here for a Capri Camper brochure.