Northern Lite unveils the final production version of the all-new 2024 Northern Lite 610; a hard side, non-slide, clamshell fiberglass truck camper for domestic half-tons. Exclusive photography ahead.

The 2024 Northern Lite 610 has finally been approved for production and is starting to ship to dealers coast-to-coast. First teased as 3D CAD renderings last September, the domestic half-ton targeting 610 has undergone an extensive design, development, and testing process to earn its Northern Lite stripes.

The most stringent testing was assigned to Brad Trites, Northern Lite’s Marketing Manager. Brad was asked to load the 610 prototype on his Ford F-150 and push the camper to the limits. Brad happens to also be an active member of Central Okanagan Search and Rescue (COSAR) and knows exactly where the challenging roads are in the Okanagan Valley.

As Brad explains it, the Northern Lite 610 stayed on his half-ton for several search and rescue operations yielding valuable insights into the capabilities of the new camper. What the Northern Lite team learned from Brad’s extended tests made the production 610 even tougher.

We wish that more camper companies will approach new model tests with such enthusiasm. Put bluntly, there’s no better way to find out if a camper is truly ready for prime time than to drive it where campers go and camp in it like campers do. Forget simulated stress testing in Solidworks. Take that fancy new camper out and beat the living heck out of it. Then you’ll know how it really works. Well done, Brad. Nice work, Northern Lite.

For more information about the 2024 Northern Lite 610, we talked to Brad Trites, Marketing Manager for Northern Lite.

Above: The 2024 Northern Lite 610 floor plan

The 2024 Northern Lite 610 is a hard-side, non-slide, toilet-only truck camper for short bed trucks. The interior floor length of the 610 is 76.5”, the interior height is 76”, and the width is 85″.

The tanks in the Northern Lite 610 are 15 gallons fresh, 15 gallons grey, and 4.75 gallons black. The camper accommodates two lithium batteries and one twenty-pound propane tank.

Northern Lite is reporting the base dry weight of the Northern Lite 610 at 1,490 pounds. The MSRP for the 2024 Northern Lite 610 wet bath is $41,240 USD.

Click here for a free Northern Lite brochure.

It’s not every day that we get to talk about a completely new Northern Lite model. What’s the story behind the new 610?

The new Northern Lite 610 was inspired by the original Northern Lite 610. The original 610 was designed for the import mid-size truck market, but we realized there was a demand for a true four-season half-ton truck camper. The new 610 builds on the legacy of the original 610, but is an entirely new design, and is focused on domestic half-ton trucks.

We’ve actually been kicking around ideas for the 610 for the past few years. We started working on it in early 2023, drawing up the initial plans. In addition, we asked dealers and consumers what they would want from a feature standpoint. Once that information came together, we designed a camper that hit those requirements while keeping the base weight under 1,500 pounds.

What makes the Northern Lite 610 a ‘true’ four season camper?

The R7 insulation, the fiberglass shell, the insulated windows, and the heated basement. You can go to -20 Celsius (-4 Fahrenheit) with water on board, or as cold as you want without water on board. Our other Northern Lite models have the same four season capability. With the 610, we are bringing true four season capability to the half-ton market.

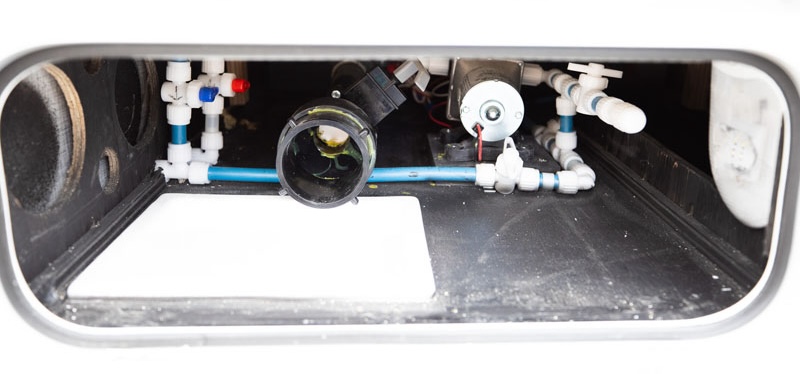

Above: Northern Lite 610 basement access showing the low water drains and dump connection

It’s rare to see a basement in the half-ton truck campers. What’s in the basement of the 610?

The heated basement is an essential element to make the 610 a true four season camper. The heated basement is 9.75” inches tall and contains the plumbing, 15 gallon grey tank, 15 gallon fresh tank, and storage. The heated basement also helps to keep the floor warm.

Why did you select a 15 gallon fresh and 15 gallon grey tank size?

Fifteen gallons was the right size for fitment and function.

The 610 was originally scheduled to debut in January. What delayed the 610 debut?

Our priority for the 610 was to build a true four season truck camper with a base weight under 1,500 pounds. The 610 also had to have the high-end quality, fit, finish, and aesthetics that people expect from Northern Lite.

“Our priority for the 610 was to build a true four season truck camper with a base weight under 1,500 pounds.”

Hitting these objectives with the right design, appliances, and materials took a little more time than we anticipated. Once we found the right combination of cabinetry, appliances, and layout, we tested it to make sure there were no structural issues and that everything worked great.

How did you test the Northern Lite 610?

The mandate given to me was to put the 610 on my Ford F-150 and put it through its paces. I’ve been involved in Search and Rescue here in British Columbia for years and knew exactly where to put the 610 to the test.

To date, the 610 has been on the road more than 6,000 kilometers (3,728 miles) on highway and brutal forest service roads. I’ve camped in it for fourteen nights and I have taken it on numerous day trips. It’s held up nicely.

“To date, the 610 has been on the road more than 6,000 kilometers (3,728 miles) on highway and brutal forest service roads.”

When I come back to the factory, the team goes over it to see if there are any issues. We made a few tweaks based on my testing. That delayed things a bit more, but it meant building the production 610 right the first time.

What tweaks did you make based on your testing?

The tweaks were minor. For example, we changed the venting a bit to now include a heat vent in the cabover. We also changed the location of the thermostat to ensure proper heating. The initial 610 design and layout were spot on from day one. All we had to do was make minor adjustments to optimize the camper.

Above: Production 2024 Northern Lite 610 models on the Ford F-150, GMC 1500, and RAM 1500

How did you decide on the overall shell length, width, and height?

That process actually started with weight. The primary factor was for the 610 base dry weight to be under 1,500 pounds. With that weight constraint, our questions were, “What can we do to maximize space for livability and comfort?” and, “What is going to be the best length, width, and height to maximize that and keep within the 1,500 pound range?”

We used Solidworks to design the camper and make sure it fit domestic half-ton trucks. The 610 fits all the domestic half-tons including late model Chevy 1500, GMC 1500, Ford F150, and Ram 1500 trucks, as well as the Toyota Tundra. If someone has an older half-ton, you have to check your truck’s fitment and payload capacity.

After designing the camper in Solidworks, we built a physical mockup and sat in the dinette, got into the cabover, and stood in the kitchen to make sure there was enough space and that it was comfortable. Then we fine-tuned the dimensions and went to the mold process.

What was the physical mockup made from?

We built a plywood mockup. It was a solid structure that allowed us to have a real feel of what the 610 layout would be. During that process, we made some immediate changes. For example, we adjusted the floor space. We wanted to make sure it felt open and roomy even though it’s a half-ton camper.

Building a mold is expensive so we wanted to make sure we had it locked down as far as the size and space. The mockup allowed us to do that.

Can the 610 also fit on three-quarter and one-ton trucks?

Absolutely. We built the 610 for domestic half-tons, but it also fits three-quarter and one tons.

One picture shows the camper on an electric Ford F-150 Lightning. Was that truck chosen for a specific reason?

We selected the F-150 Lightning to see how it would fit and handle on that truck. It fit well and we were pleased with how it looked. It was a fitment and handling test.

Were there any new fiberglass materials or processes used in the development of the Northern Lite 610?

We are employing the same dialed-in fiberglass material, resin, and manufacturing approach for the 610 as our larger truck campers. As a result, the 610 is as strong as our other models.

What material is the cabinetry made from?

We tried several different cabinet materials during the prototyping of the 610. Some were thin and light, but the finish or consistency was not acceptable. Some had finishes that looked fantastic but easily scratched.

The material we chose to use is a lightweight 5/8 inch plywood core with a 3D laminate. It kept the weight down and is abrasion and marking resistant.

Some of the cabinetry in the 610 appears to be CNC cut. Has Northern Lite acquired a CNC machine?

No. Even though we have an in-house cabinetry shop, we took a different approach with the 610 with outsourced CNC-cut cabinetry.

Is Northern Lite moving to CNC cabinets across the board?

Not at all. We will continue to build the cabinets for our larger models in-house. CNC was a necessity for the 610 to keep the weight down.

Will the 610 cabinet color and style be brought over to the Northern Lite 10-2, 9-6, and 8-11 models?

That remains to be seen. Developing the 610 gave us the opportunity to try new materials and appliances. Consumer response to the 610 will guide future decisions on our larger models.

How important was the cabinetry netting to saving weight in the 610?

To hit our weight target, we had to look at every way to save weight. Putting on wood cabinetry doors could add thirty to forty pounds throughout the unit. If we did not meet the weight target and have all of our boxes checked, we wouldn’t have made the camper.

What material is the countertop?

The countertops are a 3D Thermafoil laminate. The countertops are CNC-cut lightweight plywood. We didn’t want to use MDF. MDF has issues when it gets wet. We wanted to have a durable and high-quality countertop.

The 610 features built-in components. Why not go modular with removable components?

We looked at both options. Going the built-in route kept the look and feel of our other campers. We want the 610 to be a high-end and high-quality camper. In our opinion, going modular detracted from that. Yes, modular has advantages, but you lose something on the aesthetic side of things. Our mandate was for a high-end four-season camper.

The 610 features a combination sink and propane cooktop. Why did you decide on a combination unit?

With the combination sink and stove top we were able to gain extra counter space. Also from price, function, and aesthetics standpoints, the combination unit was the best option for the 610. The Lagun table system acts as a secondary food prep area.

Tell us about the 12-volt refrigerator in the 610.

The 610 features a Norcold N2090. It’s a12-volt three-cubic foot compressor refrigerator. For the space that we have in the 610, it was the best option. I have been camping in the 610 for the last two months and there have been zero issues with the Norcold N2090. It’s efficient and the amount of refrigerator and freezer space is good.

Why did you decide to install a cassette toilet in the 610?

We didn’t want to go with a wet bath because of weight. Having a flush toilet would mean another holding tank and more infrastructure. A porta-potty doesn’t have a quality feel and it didn’t meet our needs. A cassette toilet fits the 610 and offers the quality and function we were looking for. It’s the best choice for this model.

Did you consider making a formal bathroom with privacy walls?

A walled bathroom was not possible within the weight target we were focused on. You can put up a privacy curtain, if you need it.

Are the windows the same acrylic type you use in the Northern Lite 10-2, 9-6, and 8-11?

Yes, the 610 utilizes the same acrylic windows as our other models. There is a larger window in the dinette and a smaller window in the kitchen.

One comment that repeated over and over again on social media was the lack of side windows in the cabover. Why are there no side windows in the cabover?

Great question. What that comes down to is the East-West cabover configuration in the 610. As soon as you put windows in the cabover, you need blinds. Sleeping East-West, the blinds would get damaged quickly from your feet and pillows. The windows would also create cold spots on your head and feet.

There is a skylight above you in the cabover and, three feet away, there are windows in the kitchen and dinette for a cross-breeze. It’s already been hot here in the Okanagan Valley with spring temperatures around 30 degrees Celsius (86 degrees Fahrenheit). I was camping in the 610 and opened up the windows and skylight. That combination brings in a lot of airflow.

Did you consider a North-South cabover, or a pull-out North-South bed for the 610?

We did consider a North-South option in our early design phase. We decided that an East-West bed was what we wanted in the 610. Livability space in the main area was maximized with an East-West configuration in the cabover.

I’m 6’3” and 220 pounds. I have ample space in the 610 cabover and it’s comfortable with room at my head and feet. There’s a full double bed up there. The only disadvantage with an East-West cabover is that you need to crawl over someone to get out.

Is the HEKI cabover skylight the same size that’s in the larger Northern Lite models?

Yes, it’s the same size and model.

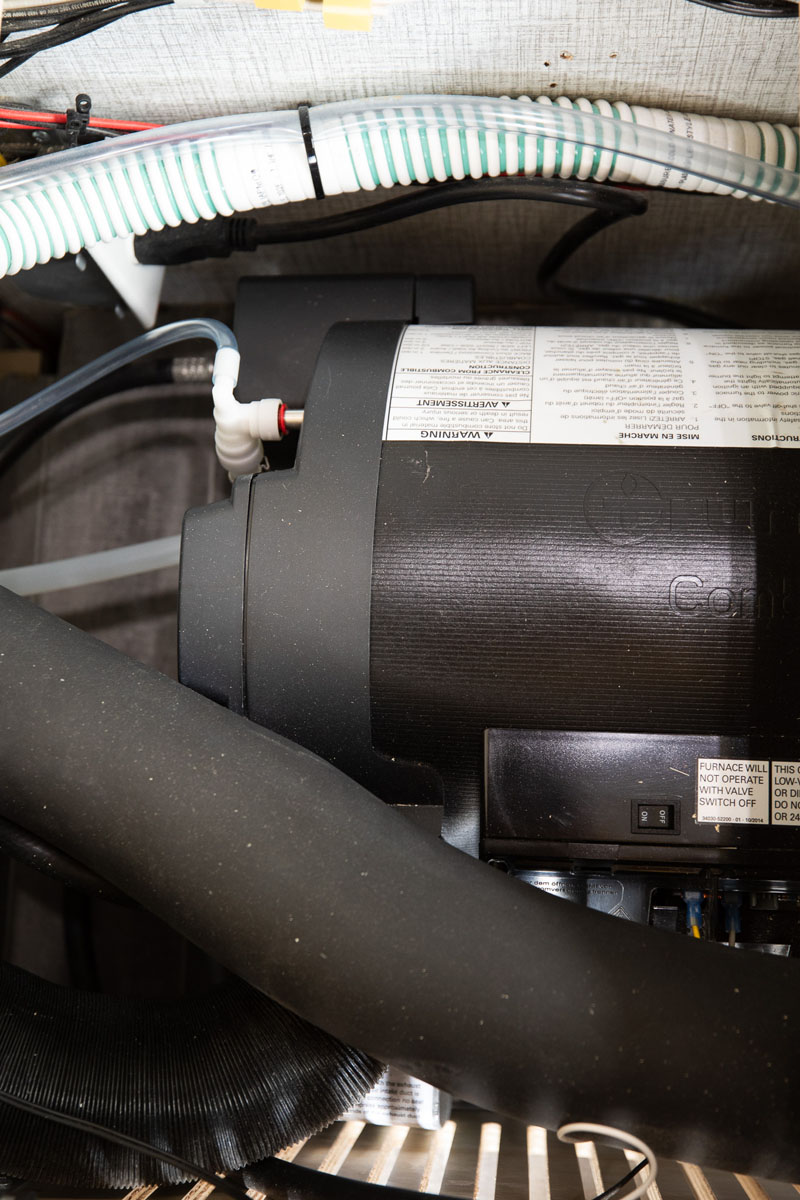

For the 610, Northern Lite chose the Truma Combi heat and hot water system. Northern Lite isn’t using Truma in the full-size models, so why did you select it for the 610?

Again, the 610 gave us the opportunity to try some new products. The 610 has limited space, so the Truma Combi was a great solution as a combination heater and water heater. It passed our testing and has proven to be a great feature of the 610. From personal experience, it’s worked out great.

“We are always open to looking at new options that make sense for our customers from a cost, reliability, warranty, and functionality perspective.”

We are always open to looking at new options that make sense for our customers from a cost, reliability, warranty, and functionality perspective. As such, if we were to find a product that would bring greater value to our customers, we would make a change.

Does this mean we might see Truma units in future Northern Lite 10-2, 9-6, and 8-11 models?

It’s a possibility.

Above: The 610 comes with 400-watts of solar standard

How many batteries does the Northern Lite 610 have and where are they located?

The battery compartment is under the seat in front of the cabover. We can fit up to two 100Ah GoPower lithium batteries there.

Does the 610 include a lithium battery?

The base package does not include the battery.

What size propane tank does the 610 have?

The 610 has one 20 pound vertical tank on the passenger’s side. The propane runs the stove, furnace, and water heater.

Is there an optional air conditioner for the 610?

Yes. We offer the Dometic Penguin 10,500 BTU air conditioner with an optional soft start. The Dometic Penguin can run off a Honda EU2200i generator.

What are the available interior fabric choices?

We have black steel or blue steel leatherette.

Will Northern Lite be offering a 610 Special Edition or Limited Edition?

Not for the foreseeable future. However, we have designed the 610 mold in a way that we have some possibilities for a minimalist and a Limited Edition style of camper.

Is there an outside or inside shower in the 610?

There’s an outside shower.

What’s the standard bumper and entry step system for the 2024 Northern Lite 610?

You can get four or five scissor steps options.

What options are available for the 2024 Northern Lite 610?

The options are limited as the camper comes loaded in its base configuration. Options include the air conditioner, AC soft-start, one or two lithium batteries, electric jacks, a rear view camera, and a microwave.

When the 610 renderings debuted in September of 2023, Northern Lite promised the 610 would weigh under 1,500 pounds. What does the final production Northern Lite 610 weigh?

1,490 pounds.

How about a fully loaded 610 including the air conditioner, two lithium batteries, a rear view camera, and a microwave?

The 610 is in the mid 1,600 pound range with air conditioner, two lithium batteries, electric jacks, rear view camera and a microwave.

Where is the center of gravity on the 2024 Northern Lite 610?

It’s 27 inches from the from the front T-wall.

What is the MSRP for the 2024 Northern Lite 610 with standard build features?

The base price is $41,240 USD.

How about a fully loaded 610?

With all of the options, it would be about $48,000 USD.

What is the warranty for the 2024 Northern Lite 610? Is it the same as your full-size models?

Like all Northern Lites, the 610 comes with a six-year structural warranty.

When will the 2024 Northern Lite 610 be available?

We have already started shipping to our dealer network.

Is there anything about the 2024 Northern Lite 610 that you would like to add?

The 610 has become my favorite Northern Lite camper, but it was also a passion project for me, so I am a little biased. It handles so well on both highways and forest service roads and driving around town is a breeze.

I have a stock 2023 Ford F150 with a 6’5 box and the camper runs amazing on it. I have since put SumoSprings on it because the camper lives on my truck full-time. I have really enjoyed seeing the 610 come from an idea to an actual product. It has actually exceeded my own personal expectations in how it turned out.

Now that you have the 610, will you build a model for mid-size trucks?

We’ve considered it. We’ll see how things go with the 610 first.

Are there any other new model announcements coming from Northern Lite in 2024?

There are no new models, but there will be updates for 2025 around July 1st.

In addition to talking with Brad, we also received feedback from Bruce Paracholski, Development Lead for Northern Lite, about how the 610 fiberglass mold was designed and manufactured. The process is more extensive than one might think.

The mold starts with a solid model in Solidworks (CAD). The solid model gets manipulated to meet the targeted truck requirements and refined for aesthetics.

From the solid model, we created a surface model and ensured that all the surfaces were knitted together making for a continuous body with no transitions. The surface model was then sent to a CNC mold shop where a male plug was created out of laminated foam.

With our stringent mold standards, we then chose to ship the plug from the CNC mold shop to our normal mold shop that we’ve engaged with for years. They understand the quality of the mold and mold finish that’s required for a Northern Lite truck camper.

Our mold shop then sprayed up multiple layers of gelcoat on the plug and sanded it to a high gloss finish. That was the surface that the female mold was created from.

Once the plug was at the required finish level, it was prepared for the next step; the creation of the female mold. During this process, the plug surface is waxed and prepared to accept the mold gelcoat. This is an important step because molds are very rigid and there should be minimal flex. This makes removing the plug from the mold more difficult than pulling the part from the mold in production. We don’t want the mold/plug to stick together.

The mold gelcoat was applied in various coats. Typically, an orange tooling gel coat is used, which is then backed up by a black tooling gel coat. This helps our fiberglass shop maintain the mold during its production life.

Once the gel coat layers are applied, the plug now looks like a solid camper top or solid camper bottom, and it gets sanded. The sanding process is a very time-consuming process, as the plug is sanded to a finer and finer grit of sandpaper. When finished, this part will have a luster similar to a finished camper.

The next step was to layer up chopped fiberglass letting each layer cure between the next application. This is done to provide a thicker/rigid part, and the layering prevents too much heat from being generated into the mold. Heat can cause distortion and finish issues.

Once completed, various methods of reinforcement are added to the mold. This can be balsa or fiberglass matting which are all used to stiffen the mold.

Finally, a welded steel frame is constructed to cradle the fiberglass mold and is bonded to the mold using fiberglass matting.

For more information on Northern Lite, visit their website at northern-lite.com. Click here for a free Northern Lite brochure.