Truck Camper Magazine visits Stablecamper in Sandy, Oregon and discovers a daring and potentially disruptive rebellion in small parts manufacturing and truck camper gear production. Load the G-code.

One of the biggest challenges to the overall quality of RV manufacturing is the quality that the parts companies integrate into their units. We can’t tell you the number of times manufacturers have voiced concerns about delivered parts that don’t pass initial inspection. It’s a real challenge that’s getting worse with every merger and acquisition of parts companies. Attack of the bean counters.

But what if there was a way for RV manufacturers to build more of their components in-house, and build them better, cheaper, and faster? Or, what if there was an outsourcing solution that kept parts’ production local, while pushing quality control to new heights? I can literally hear industry leads saying, “Yeah, that would be awesome. Bring it, Gordo!”

Enter Stablecamper. We first met Jared and Candice Sund, the Founders of Stablecamper early last year. They were hard at work developing their camper stabilization system and looking for ways to successfully bring it to the market. The last hurdle they needed to leap was cost. They needed a way to price the system competitively without sacrificing quality.

When they attempted to source their parts locally, the resulting cost was far too high. When they considered having their parts manufactured overseas at a lower cost, the quality was far too low.

Undaunted, Jared and Candice simply invented another way, and created a new and possibly revolutionary high speed, low cost and 100-percent local parts manufacturing method. Oh, and their truck camper stabilization system is utterly fantastic, too.

Buckle up buttercup. This is one heck of a factory tour.

In a nutshell, Stablecamper has combined multiple CAD software and CNC hardware technologies to produce short part runs faster and more efficiently than previously possible.

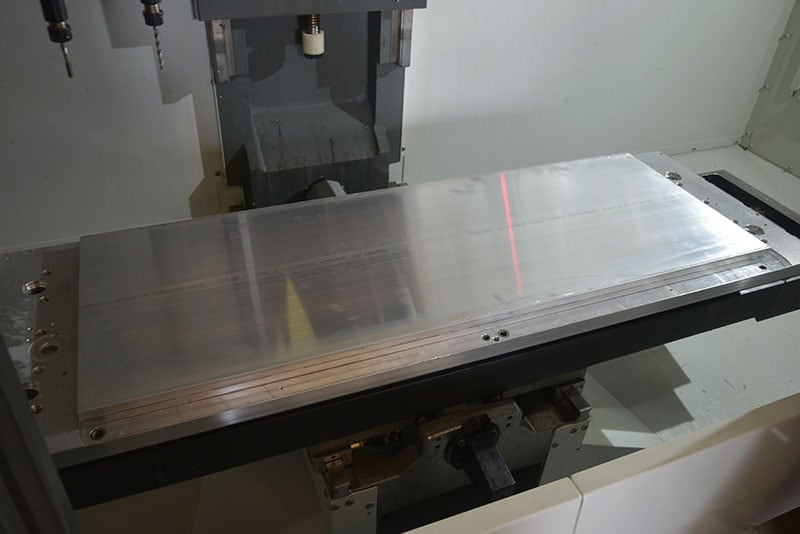

Above: Jared placing a pattern plate into the Haas TM-2P CNC mill

First up, they purchased a 10,000-pound Haas TM-2P CNC vertical milling center. From the Oxnard, California factory, the TM-2P runs at 6,000 RPM, twice as fast as competitive CNC mills.

By employing custom cutting tools running at 60-percent engagement depth, Jared was able to achieve significantly faster and wider passes with the Haas. After additional modifications, Jared increased the Haas cutting rate from 10-inches a minute to 117, a 1,070-percent increase in speed.

Next Jared designed an aluminum baseplate and a system of quickly interchangeable bolt-on aluminum pattern plates to allow for cheap tooling, fast set-up and efficient use of material. Perhaps the coolest part of this concept is that the Haas mill itself creates its own baseplate and pattern plate tooling.

The Stablecamper team found more efficiencies and speed enhancements through advanced use of Autodesk Fusion 360 software. Jared has extensive experience in developing what he calls, “digital definition products” using this CAD technology and synthesized best practices to create their advanced manufacturing process.

The sum total of Stablecamper’s manufacturing process is the ability to quickly make their aluminum and steel parts in short runs at a fraction of the cost previously possible. Nearly everything they make is designed in Autodesk Fusion 360, goes straight to the Haas CNC mill, and uses the best available materials.

Jared’s bigger vision is to spur a small parts manufacturing revolution. Stablecamper is already providing small part run services for businesses near Sandy, Oregon. If Jared and the team achieve their larger goal, there will be similar production shops in Sacramento, Salt Lake City, Saint Paul, Savannah and beyond.

Who knows, perhaps a Stablecamper-style manufacturing facility will find its way into a few truck camper manufacturers as well. You said, “Bring it”. I say, “Go get it.”

Jared has been a machinist his entire life and has a deep background in mechanical engineering, mechanical design, and software development. Prior to launching Stablecamper, Jared was the Director of Product Development for a multi-national engineering and entertainment software company.

We asked Jared to take us through the process of machining the components of a Stablecamper system. This is not unlike asking a Major Leaguer to play an inning of tee ball. Thankfully, Jared was extremely patient with us and explained the basics of CAD design, CNC programming and CNC operation step-by-step and in English. Even then we said, “Wait, what?” about 100 times.

To begin, Jared opened Autodesk Fusion 360 (computer aided design) software on his laptop and showed us the component he would be sending to the Haas TM-2P CNC vertical mill; Stablecamper square clamps for Happijac jacks. Stablecamper’s round Reico-Titan and Atwood jack clamps are also made in-house.

Prior to visiting Stablecamper, I envisioned their CNC equipment to operate something like a giant laser printer. Surely you just design something in CAD, press “Go” on the computer, and the CNC machine instantly makes what you designed, right?

Well, that’s not how this equipment works. The actual process requires a considerable amount of hands-on labor, not to mention the extensive training and experience to operate the software and machine. Unless you’re a machinist and software engineer Jedi like Jared, don’t expect to buy a Haas tomorrow and expect use it anytime soon.

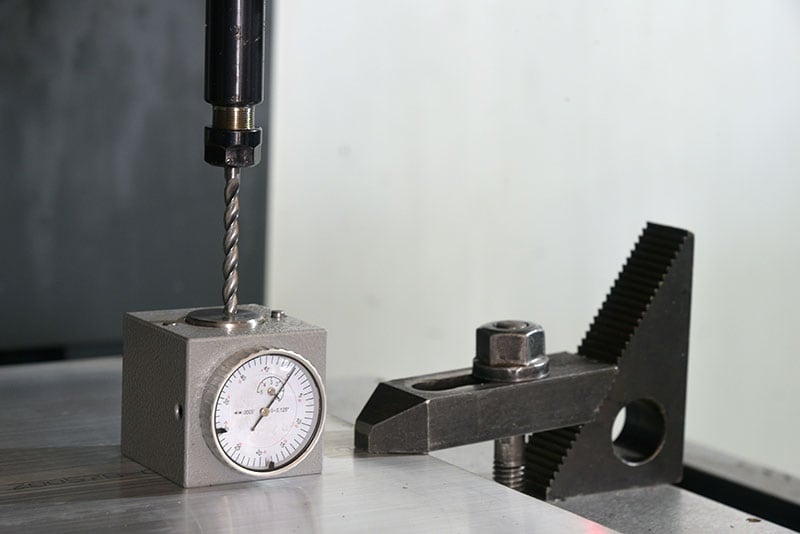

Before we were even able to get to the first cut, Jared had to calibrate the mill. This meant guiding the routing head to the precise center of the table so it would know exactly where it was (X and Y coordinates). The level of required accuracy is extreme, as is the resulting quality of what this mill produces.

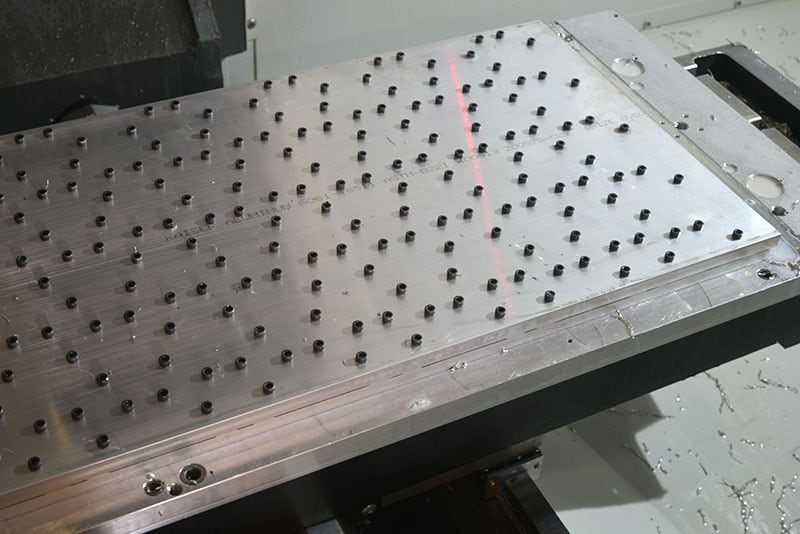

Once the mill was calibrated, he installed the aluminum pattern plate for the square Happijac clamp. If you look closely, you can see literally dozens of triangular “clamps” across this aluminum plate.

To ensure the aluminum pattern plate does not move, it’s tightened down with eight strategically placed Hex socket bolts. Jared is wearing black Nitrile gloves to avoid cuts from the sharp aluminum and tools.

With the template tightened down, Jared placed a blank aluminum plate into the mill. Stablecamper employs 6061-T6511, a precision-hardened aluminum alloy used by the aircraft and aerospace industries for its high-strength to low-weight ratio.

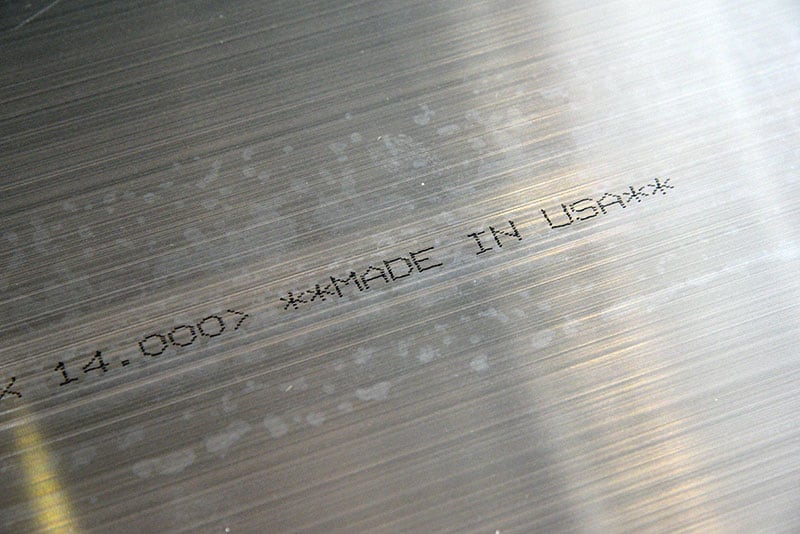

We were happy to see that the aluminum Stablecamper is using is made in the USA. To be exact, this plate was produced by Kaiser Aluminum, a company founded in 1946 with 12 facilities across the United States that ship over 600-million pounds of product annually. Go USA!

To keep the plate from moving, Jared tightened it down with two clamps; one on either end. These clamps will hold the plate during the initial cycle to bore a series of holes. In turn, these holes will take hex socket bolts to secure the blank plate to the aluminum pattern plate and table underneath.

Before the mill can begin routing, the tip must be set to the “0” reference point using a Z-axis setting indicator. When this step is complete, all 3-axis are set on the mill.

Jared has equipped the Haas TM-2P with 17 tools. This allows the machine to cut different widths, depths and finishes. It was amazing to watch the tool carousel automatically rotate, return and retrieve these tools at Jared’s programmed command.

As a journalist, I’ve been known to poke my camera where it’s not exactly safe. I once killed a relatively new camera lens in a Northern Lite fiberglass booth and nearly burned myself into oblivion on a Hellwig Products furnace backing up for a shot. There are more stories of my photo misadventures, but never was I consciously putting myself in harm’s way. I want to get the shot, but I’m not dying to do it.

Noting my enthusiasm, Jared warned me that the Haas mill doors would always be shut during operation. That’s when I saw what has to be one of the best danger warning stickers of all time.

Across the front of the CNC head is yellow triangular horror show. These may only be graphics, but I could hardly look at what was depicted.

Look at the third yellow triangle from the left. Somehow a guy has a drill bit literally sticking out of his forehead with blood gushing up and down. I also like the first red-crossed circle showing a guy stepping into the machine. At some point Darwin’s theory has to apply, right?

With the front doors safely closed, Jared called up the program for the square Happijac clamp. The program was written in G-code, the most common language for computer controlled machines. Essentially, G-code tells the Haas mill how to make the square clamp.

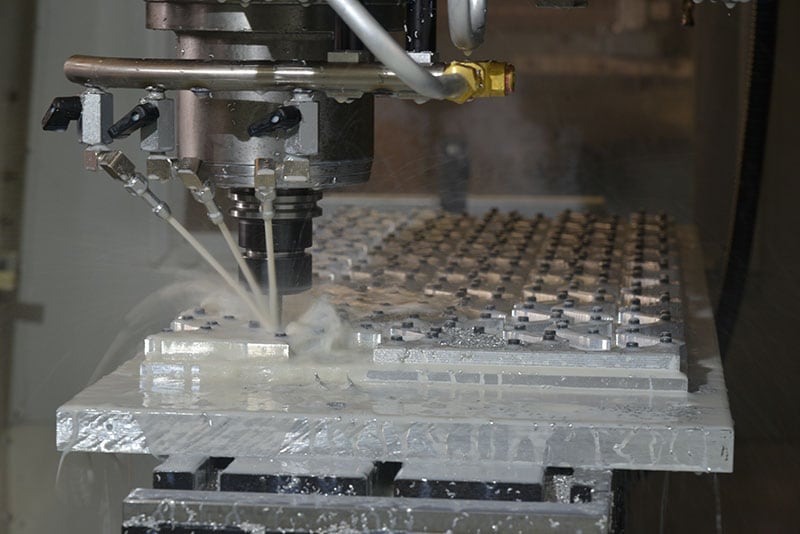

Jared checked the aim of the three liquid jets that cool and lubricate the bit during operation and hit “start”. Instantly the machine came to life executing the program to drill 320 holes into the aluminum blank.

When the holes were completed, Jared stopped the mill and opened the doors. That’s when the real work began; screwing in 320 hex socket head bolts with electric drills.

For this time-intensive task, Jared’s wife and Stablecamper co-conspirator, Candice, joined the effort. One by one, Jared and Candice hand-inserted the hex socket head bolts and then drilled them into the aluminum pattern plate below.

The purpose of these bolts is to firmly hold the aluminum blank while the Haas intricately routs the material. The position of the bolts has been carefully programmed to hold the finished parts in place and avoid contact with the mill tool.

Here’s what the aluminum blank looked like with all 320 hex socket head bolts in place. The process took Jared and Candice about a half hour to complete.

Bolts in place, Jared shut the front doors on the mill again and hit, “Start”. Before our eyes the aluminum plate disappeared revealing rows and rows of clamps bolted to the pattern plate underneath.

Observing the computer controlled precision and flowing liquid was nothing less than mesmerizing. This might be the way to get kids (and adults) to put their smartphones down. Just take them to a Haas mill and push, “Start”. They’ll be hypnotized.

As the mill was running, aluminum shavings and fluid exited the bottom of the machine. Jared explained that the mill requires routine cleaning and maintenance for optimum performance.

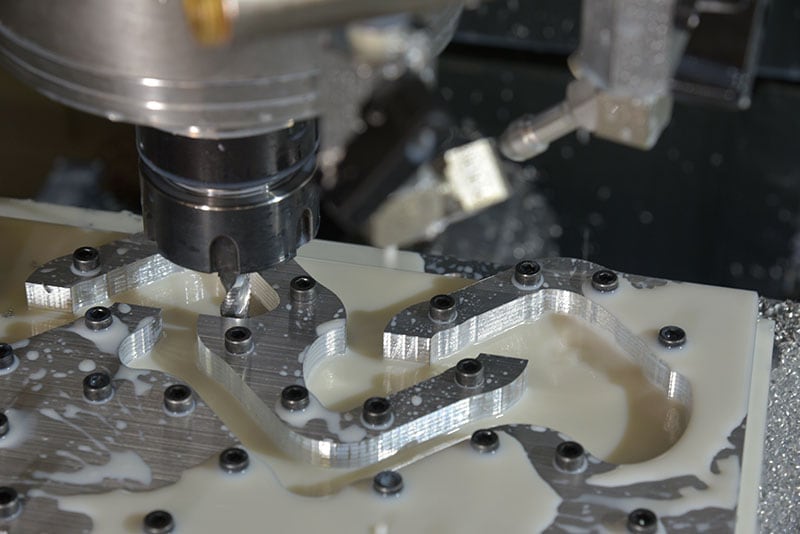

I asked Jared to stop the machine to get a photograph of the process about mid-way. In the image above you can see the parts emerging from the aluminum.

About a half-hour later later the Haas completed its task. When Jared opened the mill doors, there were 80 completed clamp parts.

The completed clamps are cut by a tool designed to cut a lot of aluminum material very quickly. This same tool leaves a rough finish on the clamps. You can literally see the tool marks on the side of the clamps that were cut with this first bit.

For a higher quality finish, another tool is selected and traces the perimeter of every clamp. If you look at the clamp in the center of the photo you can see this higher quality finish.

After the second pass, Jared sprayed down the sheet with water to remove any remaining shavings. The completed clamp components were beautiful; shiny, perfect, and ready to be unbolted.

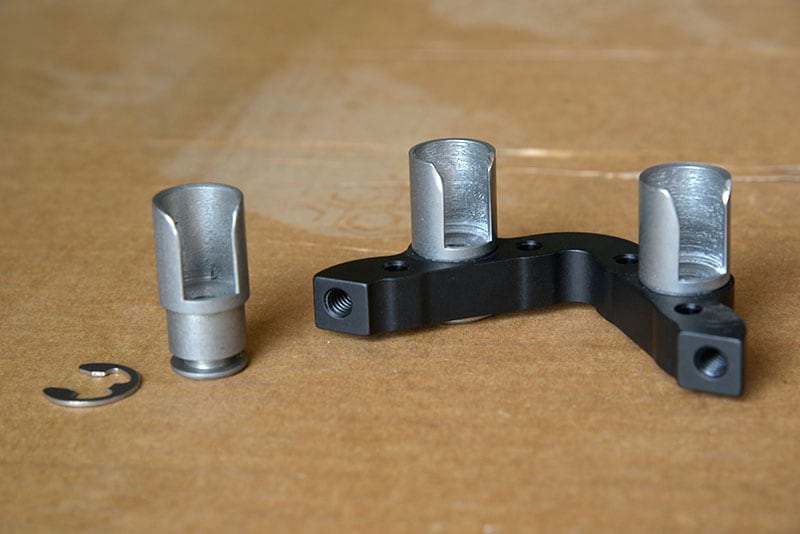

Stablecamper sends the completed parts out for anodizing (clamps) or powder coating (poles). For the best quality control, all of this work is done locally by the same vendor. As you can see, the end result is stunning.

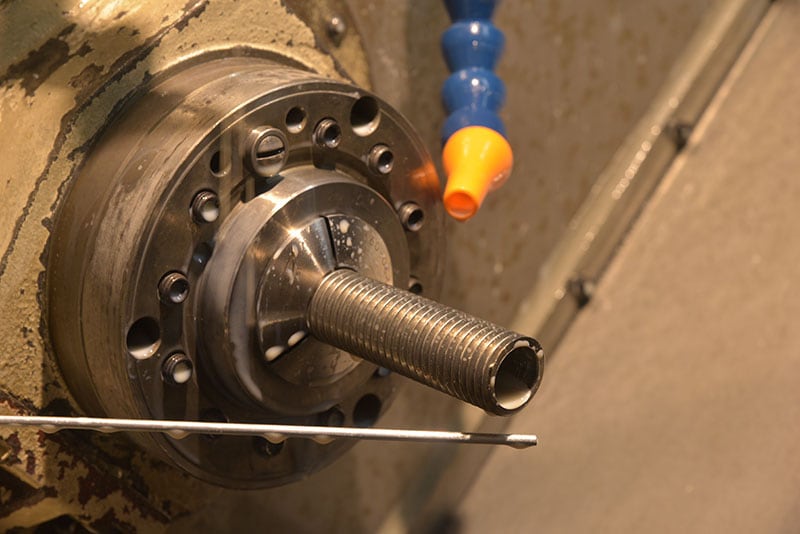

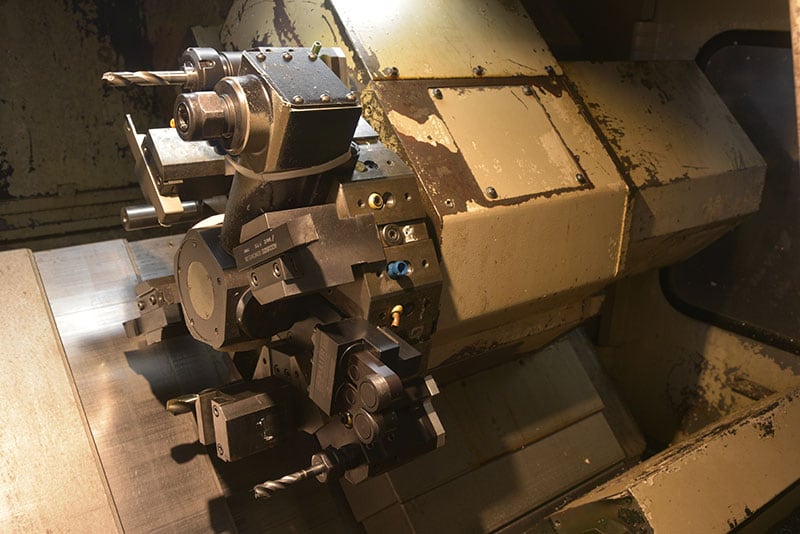

A few feet from where Jared and Candice were operating the Haas CNC mill, Jared’s father, Jim, was working the Hardinge Conquest 42 CNC turning lathe. At least that’s what it was when they got it.

The Conquest 42 dates back to the late 1980s, long before the flat panel monitor mounted on the top left of the lathe would have been available. As it turns out (literally), this lathe has been extensively hacked and upgraded by Jim and Jared.

Not only have the CNC internals been improved for speed and accuracy, but the father and son team have also upgraded the computer and software that run the machine.

While taking us through the many enhancements he had developed, Jim explained the operation of the lathe. In this photo are the spindle and clamp that hold the material to be cut.

Opposite of the spindle and clamp is the tool carousel. These computer controlled tools (or bits) are what cuts the material that turns on the spindle.

As with the Haas mill, safety required the door to be closed during operation. Unfortunately, this made photography of the material processing darn near impossible. Just imagine fluid and metal shavings spiraling at incredible speeds and you get the picture.

Once completed, the final lathed results are gorgeous. The Hardinge Conquest 42 may be decades old, but the resulting quality is state-of-the-art for the truck camper marketplace.

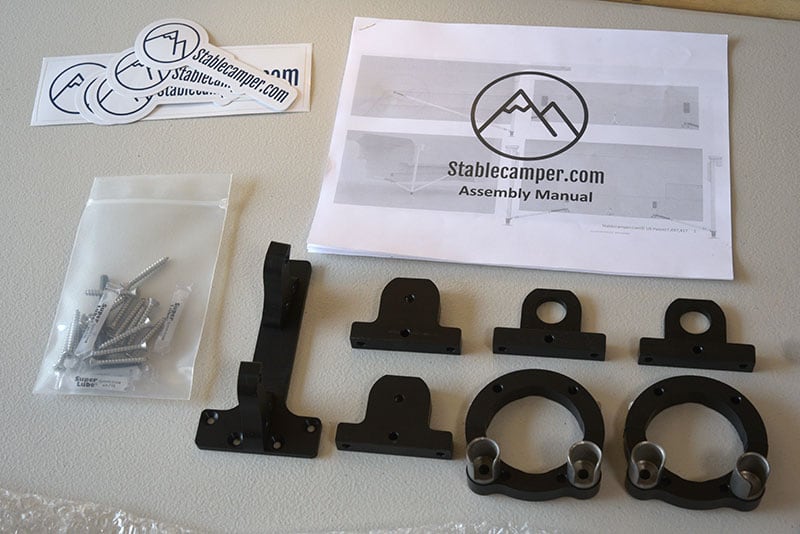

When the Stablecamper tubes, clamps, and other required hardware have been milled, lathed, anodized, and powder coated, Jared and Candice assemble the components into camper and jack-specific kits for shipping.

The kits arrive pre-assembled and ready to install.

All of the required hardware and screws are included. The step-by-step manual was designed to be easy to follow, and Stablecamper is available for any needed phone support. They even include a few Stablecamper stickers just for fun.

Here’s everything you get with a complete Stablecamper system.

The components are well packed and protected before they’re placed in the shipping box.

Here’s how the Stablecamper system arrives at your doorstep.

Just the Beginning

Along the way to developing the Stablecamper product, the Stablecamper team created something even more exciting; a ground-breaking methodology to produce short run aluminum parts better, cheaper and faster. The result of this effort is plain to see in the quality of their camper stabilization product and its competitive price.

This was one of our most unique factory tour experiences. Jared and Candice were eager for us to understand the quality of their manufacturing and the forward-thinking concept and process that makes it possible. One thing is certain; this team thinks big, and they’re not stopping with their first product.

Click here to request a free brochure.