Truck Camper Magazine tours NüCamp RV’s Cirrus camper factory in Sugarcreek, Ohio and is bowled over by the scale of their facility. If you thought Cirrus was a small operation, think again.

As a magazine, we believe no one should professionally write about a topic they haven’t experienced as a consumer or seen the full industry spectrum; raw materials to final product, initial sale to long-term maintenance, and everything in between.

To that end, we have made a point to visit every truck camper manufacturer coast-to-coast as soon and as often as possible. Not only do these visits inform our content and perspectives on the manufacturers and their products, but it also gives us the opportunity to share what we discover with you.

Speaking of discoveries, NüCamp RV debuted the Cirrus truck camper line almost two years ago at the 2014 National Trade Show in Louisville, Kentucky. Their first truck camper was a total shock to the truck camper marketplace, as were many of NüCamp RV’s forward-thinking concepts and design elements. Cirrus definitely brought something fresh to the truck camper scene.

After interviewing the Cirrus management team and studying their initial product, we were very excited to see their production facility and study their manufacturing process. The stars finally lined up on our way out to the annual Elkhart Open House this past September.

In addition to the following factory tour story, we recommend reading the Cirrus 820 announcement and Cirrus 820 review to fully understand the Cirrus camper and its many unique systems. You’ll benefit greatly from the background as you read the following factory tour.

The NüCamp RV factory was already quite sizable, and that’s before the massive expansion that was nearing completion during our visit. You can see the new addition on the right half of the photograph above.

If this building was 100-percent dedicated to truck camper production, it would easily be the largest truck camper factory in the world. In reality, Cirrus will share this facility with at least three other NüCamp RV towable production lines.

This photo, taken from inside the new addition on the second story, shows where the Cirrus production line will be moving to. The Cirrus management and production teams are excited about the new efficiencies and capacity the additional space will allow.

The rest of the new addition is just huge. The white wall in the middle offers a second floor of production and material storage potential. You can also see the main plant lit up beyond that point. If that’s not enough, there’s a second story production area behind where this photo was taken.

About fifty yards from the main plant is a repair building. This is where customer units are brought for warranty work. NüCamp RV also uses this building for research and development.

To the left of the main employee door is a shed full of bicycles. A good number of the NüCamp RV and Cirrus production team are local Amish craftsmen and women.

The Cirrus Production Line

Where the majority of truck camper manufacturers start their build process with wood or aluminum framing followed by lamination or hung wall construction, you will not find a raw material, framing, or lamination station on the Cirrus production line. The raw material processing, welding, and lamination processes are all outsourced to companies that specialize in those services.

Specifically, L&W Engineering supplies the Cirrus aluminum-frames and Amerimax Fabricated Products handles the lamination. Welded frames and laminated and CNC cut walls are then shipped directly to the Cirrus production line by these two suppliers.

NüCamp RV also outsources its Cirrus cabinetry to an Italian firm that specializes in high-end Lite-Ply cabinets. Another local Ohio vendor supplies the drawers. As the NüCamp RV leadership has explained to us, outsourcing allows Cirrus to offer a better quality product while controlling costs and increasing their production capacity.

When Scott Hubble, CEO of NüCamp RV, first brought us to the production line, we stood on the second floor cabinet assembly area and saw a straight row of eight Cirrus 820s. Underneath us at the first station was a ninth unit. If there were any doubts that NüCamp RV was serious about the truck camper industry, seeing this production line buzzing with activity put that thought to bed. Cirrus is serious.

A few feet behind where we had stood, we met Al Swartzentruber assembling the Italian cabinetry and locally sourced drawers. Al is the only one who works in the Cirrus cabinet assembly shop and he is responsible for supplying the production line with all of their cabinetry requirements.

The quality of the cabinets and drawers is simply stunning. Here you can see the dovetail joints of the Cirrus drawers. These might be the finest quality cabinets we’ve ever seen in a truck camper factory.

In the shelving surrounding Al are CNC cut components ready to assemble into finished cabinetry. For shipping efficiency, the cabinets are shipped as flats. The pre-cut inventory is then carefully counted and inventoried to ensure the new cabinetry orders and shipments are made on time. When you’re ordering product from Italy, you need to keep your lead times in check.

Immediately underneath Al’s cabinetry assembly shop is where the Amerimax side walls, front walls, rear walls, floors, and roofs are housed. There are several steps before these components will be ready for the production line, but the welded aluminum framing, lamination, and CNC routing has already been done by L&W Engineering and Amerimax.

Seth Sulzener has the incredibly detailed task of applying the intricate graphics on Cirrus truck campers. With Cirrus campers coming in different colors, and with different accent graphic colors, there’s a lot of complexity to Seth’s work.

In addition, the Cirrus logo has colors interwoven together, and final pattern adjustments are sometimes made with a razor blade. Put another way, Seth is quite the artist.

Once the graphics are applied on the driver and passenger sidewalls, Seth installs the compartment doors, windows, and many other exterior features.

For the record, no other truck camper manufacturer applies the graphics and installs the windows and cabinet doors prior to assembling the unit. Through its own efficiency studies, Cirrus decided these tasks were better suited to the front of the assembly line.

When Seth is done, he has two nearly-completed sidewalls ready to be attached on the production line. The decals are on. All the windows are in. All the cabinet doors are attached. Everything is sealed. From the right perspective, these finished sidewalls look like inch-thick Cirrus truck campers; two-dimensional truck campers!

At the very next station, we met Keith Miller building Cirrus basements. In the above photo you can see the fresh (white color) and grey (black color) holding tanks. These tanks are shaped and angled to improve drainage, maximize capacity, and help with weight distribution.

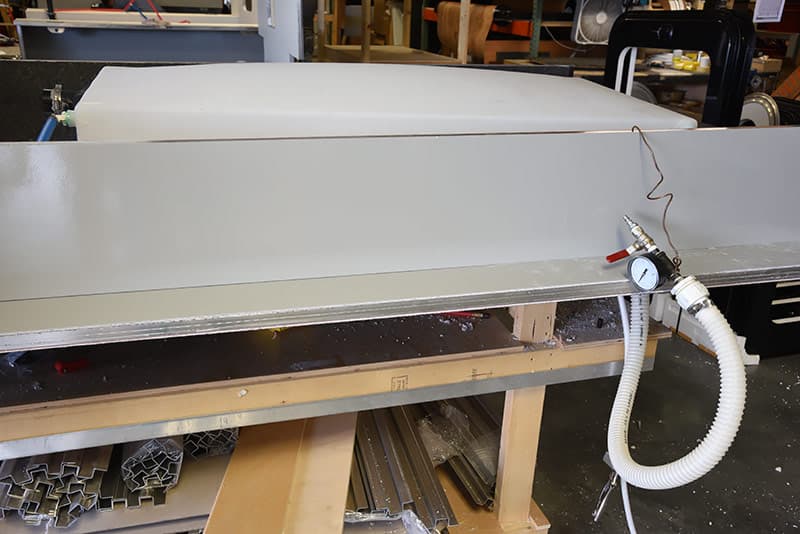

With the holding tanks installed, Keith checked the integrity of the tanks and their connections by pressurizing the tanks. In the above photo, you can actually see the fresh tank bulge under the pressure Keith has applied. To pass the tests, the tanks and their associated fixtures and plumbing are required to maintain pressure for several minutes.

With the basement upside down and easy to access, Keith attached the SeeLevel gauges to the holding tanks. These strips send the SeeLevel monitor inside the camper a much more accurate reading than traditional tank monitors. NüCamp RV spared no expense when selecting the technology and components for their Cirrus truck camper line.

Here Keith is attaching the front wall of the camper. Like the sidewalls, the front wall is another outsourced element that’s been prepared for the production line.

Once Keith completed the basement plumbing and wiring, he installed the aluminum cross members, additional insulation, and camper underbelly. This unit is almost ready to flip.

The basement has now been turned right side up. Keith is applying a layer of adhesive over top the aluminum framed Azdel composite floor. The grey material receiving the adhesive is Azdel.

Adhesive applied, Keith then installs the woven vinyl Infinity brand flooring material. Unlike most linoleum or faux-wood truck camper floors, this marine-grade material is luxuriously soft under foot.

With the flooring laid, Keith begins to install the convectors for the Alde hydronic heating system. These convectors provide silent radiant heat throughout the camper.

The next station on the production line takes us back up to the cabinetry shop. Once Al has completed a Cirrus cabinet set, he lowers the cabinets from his second floor cabinet shop to Nate Yoder. This is done either by sliding the cabinets down a large chute to be caught by Nate, or by lowering the cabinets at the end of a large pole and hook.

For reasons I can’t fully explain, this was quite fun to watch. Here you see Nate about to catch a “flying penguin”. Penguins are the cabinets located in the front cabover nose of a truck camper. They’re called penguins by the industry because they’re kind of shaped like the aquatic flightless birds before they’re installed. You can’t make this stuff up folks.

Here’s where another unique feature of Cirrus’s approach to truck camper construction really kicks in. As Nate receives each assembled cabinetry component from Al, he places the cabinets into the unit and secures them into position. Within a remarkably short period of time, he will have installed the majority of cabinets.

Watching Nate place and install the finished cabinets was like watching someone complete a giant puzzle.

This picture shows what the cabinet puzzle looks like once its almost completed; the upper and lower CNC-cut Italian cabinetry is now in place.

Alde convectors are installed in the front nose as well as both sides of the cabover. These convectors are designed to heat the cabover evenly.

Here Nate is installing convectors behind the kitchen cabinetry. Another advantage of the Alde system is that it heats the entire camper, even inside cabinets.

The Alde Compact 3010 is installed under the rear-facing dinette seat. Once it’s placed, there is still plenty of room to access the unit and the required connections.

Once the Alde system and its associated plumbing is completely installed, the entire system is pressure checked. The hot and cold water plumbing systems are also pressure checked at this time. By checking the integrity of these plumbing systems before the sidewalls are installed, any potential leaks can be quickly found and fixed.

The fold-down sink in the Cirrus 820 bathroom remains a unique feature in the truck camper marketplace. Here you can see the custom jig Nate uses to hold the sink in position while he makes the plumbing connections. Once the connections are made, the jig helps Nate correctly position and install the sink.

When we first saw the Alde heating component in the Cirrus 800 wet bath, we wondered how this aspect of the system would handle direct contact with water. This photo shows the back side of the Alde heating component that’s installed into the Cirrus 820 wet bath. As you can see, it’s nearly 100-percent aluminum and designed by Alde for direct water exposure.

Wendell Yoder installs the propane and electrical systems and components on the Cirrus production line. Here he’s installing the insulated aluminum propane compartment and connecting the propane lines.

Wendell is also responsible for the installing, wiring, and configuring the Rieco-Titan jack controller. This controller will be accessible via an outside compartment in case a fuse needs to be checked or replaced, or the wired red backup remote is needed.

It’s one thing to talk about lightweight construction, and quite another to watch two guys pickup an entire camper sidewall and walk it over to the production line. Look carefully and you’ll see Nate using a removable suction-cup handle for a secure grip.

Seconds later, they’re at the next station and installing the sidewall onto a unit. Pickup to placement took less than two minutes.

Once the sidewalls are in place, the aluminum-framed, closed cell foam, and Azdel composite roof structure is lifted into position and screwed into the main structure of the camper. Cirrus Campers utilize an aluminum roof skin but we were not able to photograph that process due to production timing.

Inside the unit, Wendell installs the Cirrus audio-video entertainment center. He later showed how the HDTV securely installs into the bracket above where his hands are, and would be easy to replace using the same bracket system.

At the next station, Stephen Borntrager installs the aluminum frame on the front nose of a Cirrus 820.

With the front nose frame in place, he added premium foil-faced insulation. The foil-faced insulation is something most customers will never see, but NüCamp RV has made it clear that they want to use the best materials and components available for Cirrus.

With the aluminum nose frame and foil-faced insulation in place, Matt Miller and Stephen Borntrager wrap Azdel composite around the contours of the nose. As a composite, Azdel cannot rot like luan plywood and offers a small degree of increased insulation.

With the final layer of fiberglass in place, Seth returns to apply the front nose Cirrus decal.

We were very interested to see how the Cirrus front window was installed. Specifically, we wanted to observe how the window was sealed and secured. Stephen explained that they use the same time tested and proven seal from their popular teardrop trailer line. One of the tricks they’ve learned is to install the seal with a small amount of tension.

After he cut the seal, I asked to see a small cross section. This close up shows the bulb seal (bottom) and the shaped grooves that tightly wrap around the nose wall and window.

The European-style acrylic thermal pane front window is installed into a channel screwed into the front nose under the window opening. Since this window opens, the final installation of the window and window struts is completed inside the unit.

Throughout the facility we found custom jigs to help the team hold and place various components perfectly every time. Here Paul Yoder is mounting the rear aluminum bumper system on a Cirrus 820 using an elaborate wood jig.

Several Cirrus production team members explained that NüCamp RV management instructed them to do whatever was necessary to achieve the highest possible quality and consistency. Many of the tools, jigs, and production processes they use stem from this progressive management approach.

Having done our fair share of camper seal work, and seen the heartbreaking results when seals are not properly maintained, we always express the importance of quality seals to the production teams we meet.

While many team members work on the seals for Cirrus Campers, Fanny Miller does the most. She explained that it took her almost a full day to complete the seals for one camper, and that she’s always going back to check and re-check her seals. We saw her numerous times double-checking her work, and cleaning the presentation of her seals.

On the final day of our visit, the team was working together to finish the last few units for the week. Here you see Nate closely inspecting the fiberglass for blemishes that need polishing and Fanny putting final touches on the all-important exterior seals.

Inside another unit, Marvin Miller is sealing the sink and range top appliances. Even though the pace of work was moving quickly, there was always a strong sense that the team wanted to get the campers done right, not fast.

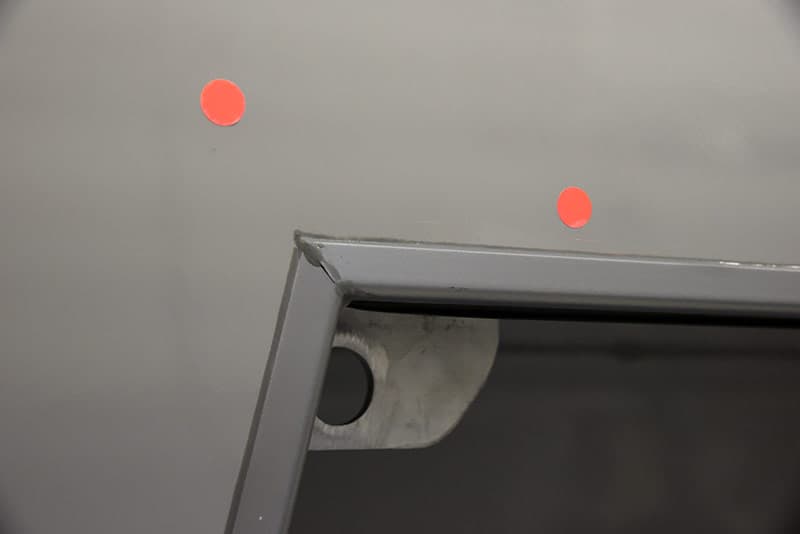

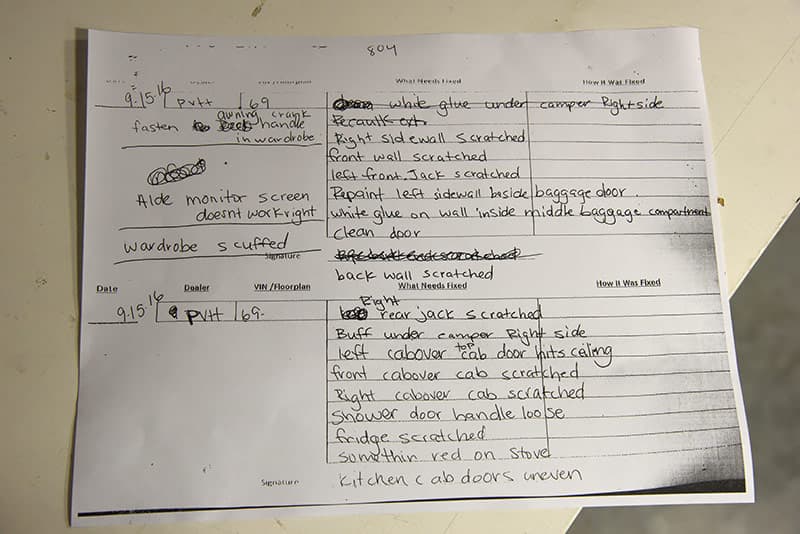

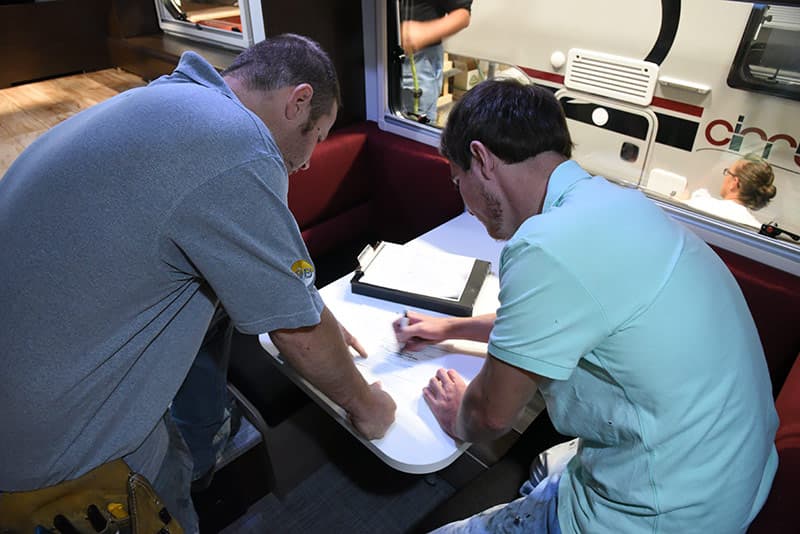

Final quality control inspection is handled in a somewhat unique way at the end of the Cirrus production line. Rather than have a dedicated Cirrus team member review every unit, they have Renee Knepp, the experienced quality control manager from the NüCamp RV teardrop trailer line, inspect every unit.

This inspection is often done after hours. When the team returns in the morning, they find florescent dots showing where the trouble spots are, and notes explaining what needs to be fixed or improved.

Once the team completes this list, Renee follows-up and checks that everything has been done prior to the unit leaving the production line.

One might assume that the relationship between the Cirrus production line and Renee might be strained given her responsibility to critique their work. However, we saw a high degree of camaraderie and respect between Renee and the team. They understand the importance of her role, and want the product to be the highest possible quality.

Working off Renee’s quality control list, Keith is fixing a small scratch on a refrigerator.

Just feet from where Keith was working on the refrigerator, Paul corrected the alignment of the cabinetry, and adjusted the latches and hardware. The changes and adjustments were subtle, but made an important difference to the way the cabinets looked, and handled.

On the exterior, Nate was buffing out a scratch on the front wall fiberglass while Matt carefully touched up the paint on a Rieco-Titan jack. Most of what they were addressing was nearly impossible to see, unless the team directly pointed it out.

At the end of everyday, the team sweeps the entire production line, and moves campers to the next station. Shop brooms in hand, four guys make quick work of sweeping the floor.

Once an area is swept, the team pulls the nearest camper forward on the line, and then sweeps the next station. This continues until the last station where they put all the swept debris in the trash. This daily practice explains why the Cirrus production line (and the entire NüCamp RV factory for that matter) is so clean.

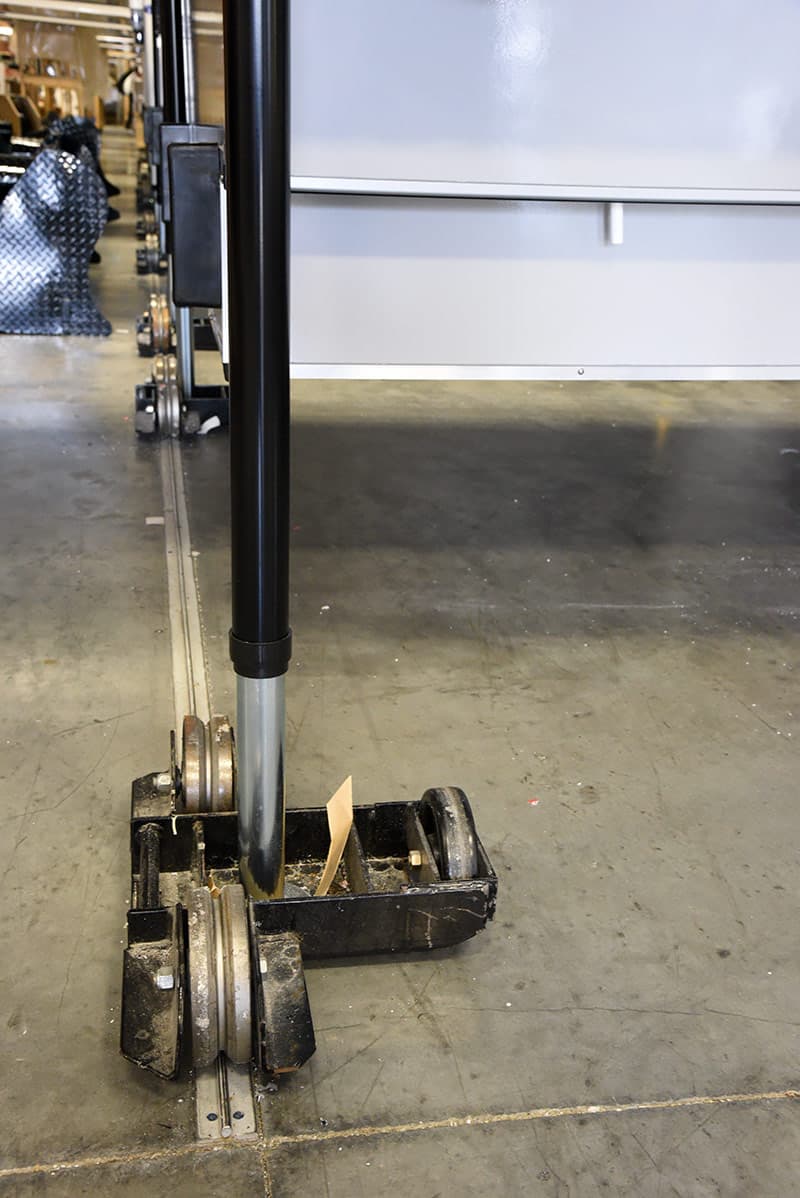

You might have noticed that the Cirrus campers are perfectly lined up. In most factories, truck campers are placed on dollies and the team does its best to keep the campers lined up and evenly spaced.

At Cirrus they have rollers under the corner jacks. The two front rollers are captured on a rail guide that keeps the campers perfectly lined-up. The rollers and guides also make it possible for two people to move a camper without fear of it going off course.

Every Friday, after the last camper of the week is approved and the production line is swept and moved forward, the team begins to prepare their stations for the following week.

To organize the materials and components they will need, team members fill a series of bins. Each of these bins contains what they will need for one camper. As they explained, the bins improve their efficiency, and ensure that they have what they need for the week.

There is one more stop for a Cirrus truck camper before it leaves the building. Campers are rolled into a dedicated water test booth to have every seal, window, and compartment sprayed with water and checked for leaks. After Ivan Yoder hoses down a unit, he inspects the inside for any sign of water intrusion. Once a camper passes this test, it’s pushed out the door.

If a Cirrus does not pass the water test, or is waiting for another round of quality control, it waits immediately outside the plant. Here you see two Cirrus units waiting for minor repairs and final inspection. You can also see the aforementioned water test booth under the number 3.

As of our visit in mid-September, the Cirrus production team was building about six units a week. In the yard, we found about 36 units, or 6 weeks of production ready to ship. Most of these units were sold to dealers and awaiting shipping.

And here they are, almost the entire Cirrus production team. Scott Hubble, CEO of NüCamp RV is on the far right, and there’s at least one production team member not pictured. Put another way, these dozen or so folks are building six Cirrus truck campers a week. That’s a very impressive output for such a relatively small team.

During our stay, we camped in NüCamp RV’s dedicated campground – with electric – about fifty feet from the plant. Even better, the campground backs up to trees and is very quiet at night. Just be ready to wake up by about 5:15am when the workers pull in. NüCamp RV rises early.

Speaking of 5:15, I have a funny story to share about our experience with the Cirrus team. At the end of day one, I was informed that the team got started every morning at 5:30am. In addition, the team told me that they might finish up the day early as they were very close to completing six units for the week.

Well, I’m no early riser, but I quietly got out of bed at 4:45am the next morning, managed not to wake Angela or Harley, and got my butt through the NüCamp RV employee door showered, shaved, dressed, and bright-eyed and bushy-tailed at exactly 5:30am.

What I saw next is something I will never forget.

Huddled around a Cirrus about half way down the line was the entire production team looking like they just woke up. Upon discovering this tired bleary-eyed group, I remembered the teasing they had given me, doubting that I had it in me to make this pre-dawn appointment.

“I see!” I said at the top of my wide-awake voice. “So this is how it really is!”

They burst out laughing, and got to work. Within minutes they were working on the campers at full speed, and putting up with me taking their pictures – at 5:35am.

What a great team.

For more information on NüCamp RV, visit their website at cirrus.nucamprv.com. Click here for a Cirrus Camper brochure.