TCM visits Future Solutions (FSI) for a bifacial solar panel installation and review. Can two bifacial 220-watt panels compete with a three-panel 490-watt setup? The results are shocking!

In mid-June, we attended the Northwood RV Owners Association Rally in La Grande, Oregon. For anyone with an Arctic Fox or Wolf Creek truck camper, the annual event is highly recommended and includes a behind-the-scenes tour of the nearby Northwood Manufacturing factory. Good times.

As part of the festivities, Northwood invited Future Solutions (FSI) to talk about the FSI battery, solar, and electrical products employed in Northwood’s campers, trailers, and fifth wheels. We attended the presentation and were genuinely impressed with FSI’s approach to integrated electrical systems.

One of the products FSI presented was a bifacial solar panel. Bi-facial solar panels have solar cells facing up to the sky and down at the camper. This might seem counterintuitive, but FSI claimed their bifacial panels produced between 5 and 30% more energy. Skeptical? So were we. Were we also curious? You bet!

After the presentation, we approached the FSI team and proposed a little challenge. We could install bifacial panels on our camper and see if they actually made a difference. The FSI team took us up on it, and we scheduled an appointment in Elkhart, Indiana, three months later.

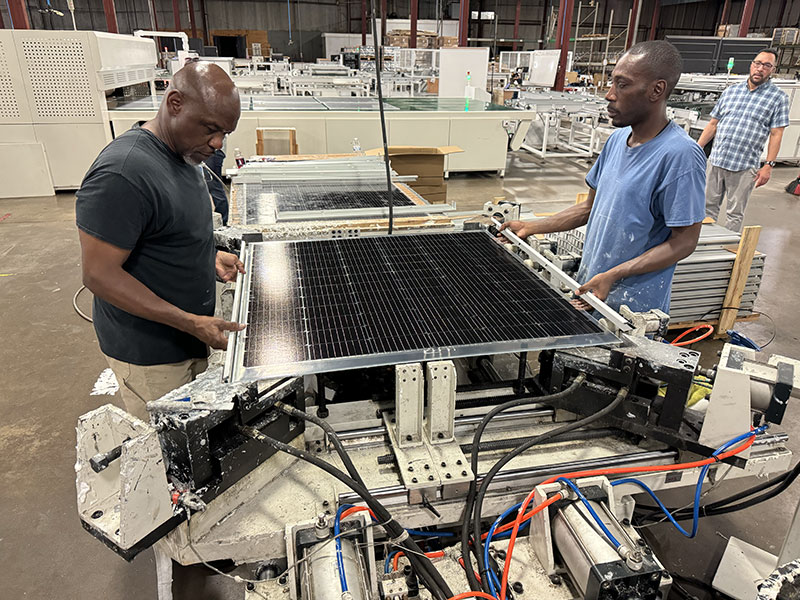

Before our install, the FSI team took us to Crossroads Solar to see how their bifacial solar panels are manufactured. Before we arrived, they explained that Crossroads is a second-chance hiring facility that employs formerly incarcerated people. The company helps these individuals reintegrate into society, learn valuable new skills, and earn a living.

When we asked if the panels are 100 percent made in the USA, they stated that the solar wafers come from overseas, but the panels themselves are assembled in Indiana. From this, we thought there probably wasn’t much to this process. Boy, were we wrong.

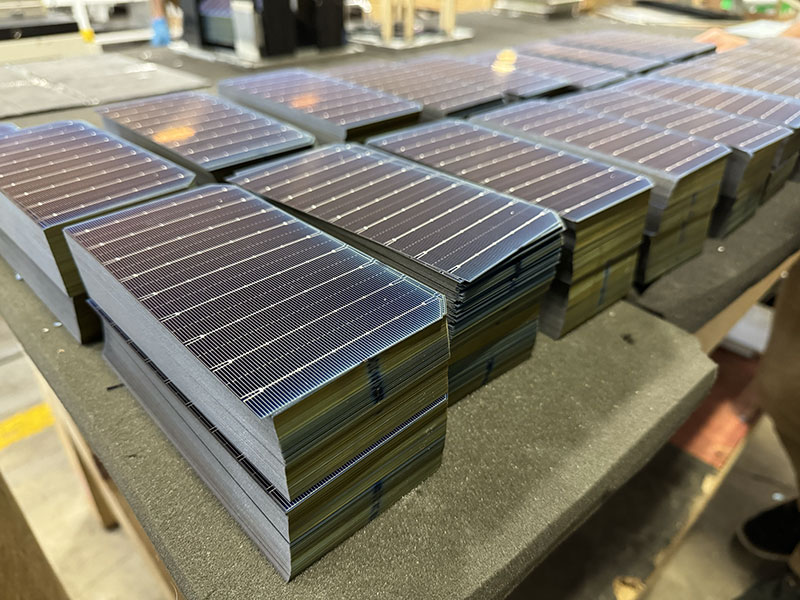

The wafers that arrive from overseas provide the foundation for the photovoltaic (PV) process. In person, these wafers (shown above) are quite beautiful and incredibly fragile. Drop one, and it’s toast. So how do you turn something so fragile into a panel you can mount to a camper roof and handle the punishment of off-road travel and weather?

The first step is a series of fully automated tests using specialized sensors and cameras to make sure the wafers are undamaged and properly functioning.

Following this process, the wafers are fed into a several meter long solar stringer machine. A solar stringer machine is a fully automated device that precisely aligns and connects the individual solar wafers using conductive adhesives or laser welding. This incredibly fast and multi-faceted machine is mesmerizing to watch.

The resulting sub-assemblies are brought to the head of a long production line, where team members layer the wafer strings together on ethylene vinyl acetate (EVA). Once encapsulated, EVA gives a solar panel its durability, weather resistance, and strength.

At the end of the production line, each panel is scanned for micro cracks. Then an infrared camera checks the panel for hot spots caused by defects.

Once a panel passes these tests, it’s laminated in another long automated machine.

On the other side, laminated solar panels are placed into a framing machine. This machine applies the proper pressure and makes sure the resulting frame and panel is perfectly square.

Then the panels get a junction box with diodes soldered in place.

Next, the panels are placed on a solar simulator that flashes a bright light to simulate sunlight. This final test ensures the performance and efficiency of every panel.

The completed solar panels are then packaged for shipping and head to FSI and other clients.

As we walked toward the exit, Angela discovered a TCM forklift. Neither of us knew that TCM (Toyo Carriers Manufacturing) is a successful brand of Japanese forklifts founded in 1949. We just assumed this was done to impress us—and it worked.

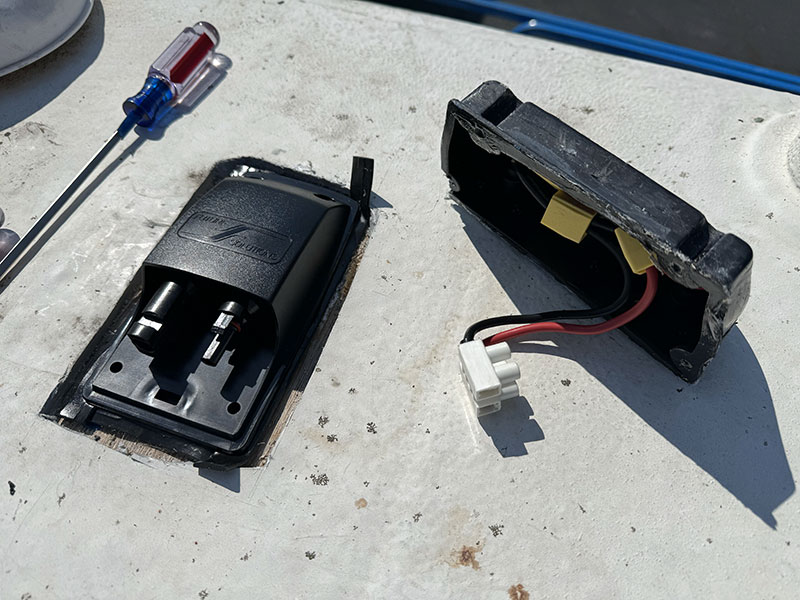

Above and below: Our FlexArmor roof with our old solar panels removed

Returning to FSI, the install team had already removed our three old solar panels and power-washed our roof. By this point, we had been on the road for four months, driven from Florida to Oregon to Los Angeles, and back through Denver and Elkhart, Indiana. Evidently, we picked up some road dirt along the way.

Our roof is coated in FlexArmor, a spray-on, 3/16 inch thick, seamless, pure polyurea coating for RV roofs. We had FlexArmor installed five years ago and have been very happy with its performance. In a nutshell, if you want a leak-proof, maintenance-free camper roof with a lifetime warranty—and are okay with the $200 per linear foot price—it’s unbeatable.

Actually, it’s almost too unbeatable. The downside of FlexArmor is that it’s a serious endeavor to remove it. To access the old solar junction box, a tech at FSI had to use a rubber mallet and a screwdriver for better part of two hours. FlexArmor is no joke!

Once the old junction box was removed, the new FSI junction box was installed and sealed with self-leveling roof sealant.

This sealant will later be removed and replaced with FlexArmor to maintain our FlexArmor lifetime warranty.

While this process was happening, we inspected our old solar panels. Our original panel was 150-watts and was installed back in 2014. To think one 150-watt panel was pretty hip back then. We got the second two 170-watt solar panels in 2019. That put our old solar panel array at 490 watts. For the record, this was more than we ever needed.

Our older panels were all the same size, but the oldest 150-watt panel had different mounting points than the more recent panels. And due to the FlexArmor, the mounting points were set into the material and could not be moved without more chiseling. For obvious reasons, that was something we wanted to avoid.

That created a challenge as the newer 220-watt bifacial panels were several inches longer than the outgoing panels. After considerable debate, the oldest panel mounting points were found to be incompatible with the new panels—at least with the brackets on hand.

With this roadblock, the decision was made to go to two—rather than three—220-watt bifacial panels. We can always add more panels down the road, but we’ll need to get new mounting points installed by FlexArmor first.

In that moment, we couldn’t help but wonder how different the wattage would be. At their best, our old three-panel, 490-watt setup produced about 260-watts; roughly half their rated output. That gap between lab ratings and real-world performance comes down to non-ideal temperatures, air mass, solar angle, heat, location, shading, wiring losses, dirt, and natural degradation. Many truck camper owners report the same: real output is often about half the panel’s rating. In our experience, that’s typical.

Could two brand new bifacial 220-watt solar panels compete with three old mixed panels totaling 490-watts? There was only one way to find out.

Once the two-panel decision was made, the FSI installation team made quick work of installing the panels, completing the wiring, checking the wiring with a volt meter, and routing and affixing the wiring on our roof with 3M VHB cable clips. These guys are pros.

Above: The solar two panels are located on the passenger side front (shown above) and rear (off camera). The front driver side panel has been removed.

After the installation was complete, the team took photographs for FSI’s records and future customer service. If we call them in a year or two with a question, they can check their photos and recall specifics.

In the days that followed, we kept a close eye on our Goal Zero Escape system to see if the bifacial panels were up to snuff. Under partly sunny conditions, we barely broke 300-watts.

Already thrilled with that number, the Goal Zero read 327-watts under full sun on day three. Under those real-world conditions, the two bifacial panels were pumping out almost 19 percent more power than our previous three-panel system. Holy cow!

Since that day, we have seen similar levels on sunny days. Whether that’s attributable to the panels being new or bifacial or both is difficult to determine. It’s also likely that the 150-watt panel from 2014 was holding back the performance of the two 170-watt panels.

Whatever the reason, our two bifacial panels are handily outperforming the three they replaced. And we shaved 12.5 pounds off the roof in the process. We’ll take that as a huge win!

For more information on FSI, visit their website at fsi-solutions.com.