Welcome to the second entry in April’s Medium Mod Contest. One Medium Mod will be published in every Email Alert in April. At the end of the month, we’ll hold a reader vote to determine April’s winner. Click here for information about the 2023 Mod Contest, including how to enter.

Gary Elliott, Advance, North Carolina

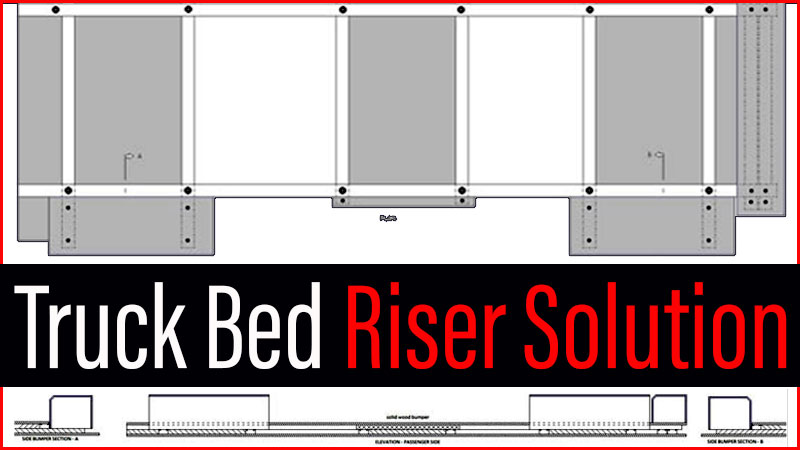

Truck Bed Riser Solution

2021 Ford F-350

2020 Northern-Lite 10-2EX

Above: Camping along the Blue Ridge Parkway in North Carolina

Being new to the truck camper world, my truck bed riser solution might be a bit of a re-hash for experienced campers. My offering resolves the fit discrepancy that can occur with an older camper and a newer truck bed. It also provides adjustable camper alignment and a movement solution to fit most campers. Width and length dimensions are modified (during construction) to fit your specific truck bed.

For this modification, a professionally applied spray-in truck bed liner is recommended.

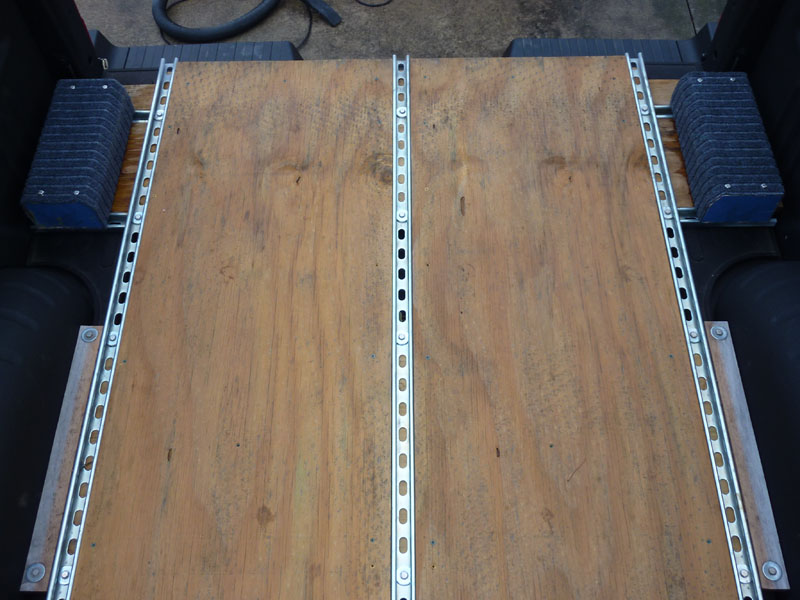

A custom-fit rubber truck bed mat from Dee Zee was installed beneath two layers of weather-resistant 3/4-inch plywood. All plywood layers are framed with 13/16-inch (standard) galvanized strut channels. The lower east-west plywood layer is fastened to the upper north-south layer where the two surfaces contact each other. Lastly, a 4-foot by 8-foot Dee Zee rubber truck bet mat completes the top layer for a 2 3/8-inch total riser height.

To assist camper alignment during loading and reduce the movement of the camper during transit, blocks of solid wood wrapped in marine-grade indoor/outdoor carpet are employed. This is an adaptation of wooden supports typically found on boat trailers. The blocks are adjusted to your specific camper width and remain bolted in place as long as desired. These blocks are used as guides for alignment. The downward weight of the camper should never be placed against or upon the wood blocks during mounting or transportation.

This system does not require holes drilled into the truck bed. None of the metal strut channel frames contact the truck bed. The upper and lower channel frames are fastened together with special channel nuts, stainless 1⁄4-20 screws, and fender washers. The second layer of plywood is comprised of two north-south oriented panels and a strut channel. The second layer of (upper) plywood panels are joined to the first layer of (lower) plywood panels with wood screws.

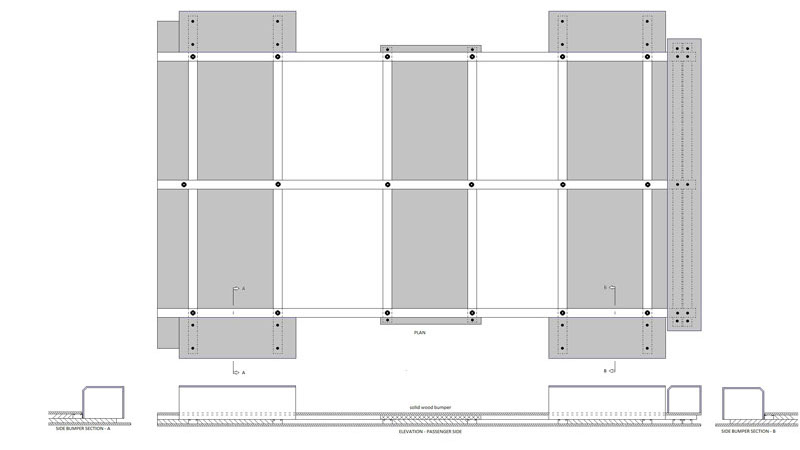

The first layer of 3⁄4-inch plywood is cut into five rectangular pieces, placed lengthwise from west to east. Length and width are determined by the panel’s location within the truck bed.

Above: Looking aft from the wheel wells to the rear bumper.

Above: The layout of Strut Channel, Wood Blocks and Lower Panel(s) placement.

Included in the first layer are two west-east strut channel pieces. These are placed between the wheel wells and cut short of contacting the truck bed on both sides by a minimum distance of 1⁄2-inch. A piece of 3⁄4-inch hardwood is attached and extends past the ends of the strut channel. The wood piece is adjusted to rest in contact with wheel wells (see below).

Above: A length 3⁄4-inch hardwood stock extends past the ends of the strut channel at both wheel wells. Panel LC (obscured from view) is placed between these 2) strut channels. To facilitate the removal of the system, Panel LC does not contact the wheel wells.

Four solid wood blocks, at the sides of the truck bed, (painted blue) are shown mounted to the lower strut channel. The side blocks are not in contact with the truck bed to allow for variations in camper width. Two of the lower-layer plywood panels (LB and LD) are fitted to make contact with the sides of the bed at their outer edges. These edge locations are associated with the four side-mounted alignment blocks (see below).

Above: Looking forward from the rear bumper. Both layers of plywood and strut channel are shown.

Immediately inside the rear of the truck bed is plywood Panel LA. Panel LA is extended a minimum of 3 inches beyond the widest dimension of the truck bed rear opening (see below).

Above: Panel LA is in contact with the rear bed pillars on both sides of the truck bed. This piece prevents the riser system from sliding to the rear of the truck.

The laminated wood beam is installed at the inside/front of the truck bed and rests in contact with the bulkhead. The beam was fabricated from several 3⁄4-inch hardwood layers glued together (see below).

Above: View of beam bolted to first layer strut channels and positioned against the bulkhead.

A laminated beam was chosen to help disperse (across the truck bed bulkhead) a load that may be experienced during unexpected and/or rapid slowing conditions. The beam also serves as the forward position limiter while loading the camper onto the truck. Wood blocks and the laminated beam are covered with marine-grade indoor/outdoor carpet to protect both the truck bed and camper surfaces.

Finally, a 4-foot by 8-foot rubber mat covers the entire second plywood layer. The mat is sandwiched between the laminated beam and the second plywood layer. Six 6-inch by 1⁄4-20 stainless bolts pass through the beam, then the mat, then the second plywood layer, and finally into the first layer of channel strut nuts. The beam is not centered above the channel, but offset to allow only the carpeted beam to rest against the bulkhead. Two strut channels are required at this location (see below).

Above: The laminated beam is offset from the first layer of strut channels. To secure the top mat, it is sandwiched between the laminated beam and the second (upper) plywood layer.

Additional Notes:

1. See chart above for additional details and construction notes.

2. Additional riser height can be achieved with 1 5/8-inch deep strut channel and increased panel thickness.

3. Other campers write about using hard board insulation panels for decreased weight and increased panel thickness. This material is not approved for its use in this riser system. The insulation material is not to be used where wood panels are intended to be in contact with the truck bed.

4. This system does not secure the truck to the camper during transportation. When transporting the camper, tie-down fasteners, as approved by the camper manufacturer must always be used.

The materials I used were a Dee Zee custom mat ($110), Dee Zee 4-foot by 8-foot mat ($100), 4-foot by 8-foot plywood ($40), strut channel ($25), strut channel nuts/screws/washers/box screws (approximately $10), 2x6x8” post ($23), 1x4x8’ hardwood ($25), marine grade carpet ($30).

It took me approximately sixteen hours to complete this mod and it cost $694.25. The level of difficulty is low.

Disclaimer: The modifications above are submitted by Truck Camper Magazine readers. It is your responsibility to make sure that any do-it-yourself modification project you undertake is safe, effective, and legal for your situation.

Enter Your Mods Now!

If you’d like to enter a modification you’ve done on your truck camper, click here. You can enter as many mods as you want, at any time. Good luck mod makers!