Torklift International revolutionizes internal tie-downs and turnbuckles with their all-new frame-mounted ApexAnchors tie-down payload anchor system, FastGun Apex turnbuckle, and Apex iXL turnbuckle. Take control of your internally tied-down truck camper with the Torklift Apex system. Lock it down!

As owners of an eleven-foot hard side truck camper, we have exclusively used Torklift International frame-mounted tie-downs and turnbuckles for over a decade. With tens of thousands of truck camping miles behind us, we have total confidence in the Torklift International frame-mounted tie-down and turnbuckle system. It’s rock solid and dependable.

Of course, all of the above pertains to Torklift International’s external tie-down and turnbuckle system. Over the past decade, there’s been a surge in internally mounted truck campers, especially within the Overland marketplace. Without a properly frame-mounted tie-down and turnbuckle solution, these campers have utilized truck bed anchor points installed by the truck manufacturer to hold a truck camper down that were never intended for a truck camper application, much less designed for the weight and center of gravity of a truck camper rig. These cargo anchor points are installed directly to the bed and designed for light duty, temporary cargo use only.

To address this challenge, Torklift International has worked with several truck camper manufacturers to design and develop an all-new frame-mounted internal payload anchor tie-down and turnbuckle system. The Torklift Apex system builds upon Torklift’s decades of frame-mounted tie-down and turnbuckle experience and adapts it for an internal application.

To find out more about the new Torklift International Apex internal tie-down and turnbuckle system, we spoke to Jack Kay, President, Jay Taylor, Torklift GM emeritus, and Kyler Morrison, National Sales Manager of Torklift International.

Above: The Torklift ApexAnchor tie-down payload anchor installed inside a truck bed

What’s the origin story of the ApexAnchors system?

Kyler: The ApexAnchors system has been in development for several years. We worked with several major truck camper manufacturers on the design, development, and testing process. The feedback from the OEMs on the new Apex system has been fantastic.

Jack: ApexAnchors are internal payload anchors. They are specifically designed to handle the payload of a mounted truck camper. Like our external payload anchors (Torklift Frame-Mounted Tie-Downs), the ApexAnchors are installed directly to the truck frame. They are 100-percent chassis frame-mounted. The only thing that touches the receiver of theApexAnchors is a urethane grommet in the truck bed.

Jay: Standard cargo anchor points found on half-ton and mid-size trucks are not designed to handle the weight and forces of a loaded truck camper. Standard cargo anchor points are designed for temporary use, to secure light cargo, and typically don’t have weight ratings. Standard cargo points are also part of the truck bed, not the frame. Truck beds are not designed to handle significant loads for prolonged periods of time.

In contrast, Torklift International ApexAnchors are payload anchor points. They are heavy-duty, bolted directly to the truck frame, and designed to handle the dynamic loads and high center of gravity of a loaded truck camper. ApexAnchors not only have the capacity to handle a truck camper, but they also completely prevent camper shifts.

“They are heavy-duty, bolted directly to the truck frame, and designed to handle the dynamic loads and high center of gravity of a loaded truck camper.”

Jack: The Torklift ApexAnchors lock the loaded camper to the frame of the truck. Together with the new spring-loaded FastGun Apex turnbuckle and Apex iXL turnbuckles, the Apex system makes a fundamental difference in truck camper safety, handling, and performance.

Jay: The ApexAnchors hold the camper and stop it from moving. The spring-loaded tie-down approach minimizes stress points on the camper, which prevents warranty issues. Compared to other products, customers are going to notice the difference, feel safe, and know their investment was money well spent.

Above: The Torklift FastGun Apex turnbuckles

At first blush, the FastGun Apex and Apex iXL turnbuckles look like mini versions of your FastGun and SpringLoad XL series. Are these mini versions of your current turnbuckles or a different design?

Jack: They’re similar in appearance, but are new designs. As internal turnbuckles, the spring load assembly needed to be at the top so you can see the spring tension indicator when dealing with limited space between the truck camper and the truck bed. On the FastGun Apex and Apex iXL turnbuckles, the tension indicator is built-in as a component of the turnbuckle.

Above: The Torklift Apex iXL turnbuckles

That’s an oversimplification of the design and how it works. The CNC, machine, and tooling investment needed to produce the parts for the ApexAnchors and turnbuckles was significant. It was a multi-million dollar program.

Earlier you mentioned working with the camper manufacturers during the development of these new products. Tell us about that process.

Jay: The OEMs actually came to us about developing a better internal anchor and tie-down system than what the truck manufacturers can offer. They wanted something more reliable that would provide constant tension, like our external tie-down and turnbuckle systems. That’s why they came to Torklift.

Jack: One of the top priorities of the OEMs was keeping the camper from shifting. When campers move during transit, they can damage bulkheads and fender wells. During our ApexAnchors testing with the OEMs, we loaded various campers and took the rigs on and off-road. We used cameras and took numerous measurements, and recorded zero camper movement. The OEMs were ecstatic with the results.

What’s the capacity of the ApexAnchors and turnbuckle system?

Jack: The ApexAnchors are rated at 2,000 pounds each.

How do the tie-down points connect to a truck frame?

Jay: Exactly how our external tie-down and turnbuckle systems do. We started with our experience in externally mounted tie-downs and turnbuckles and designed and developed our internal tie-down and turnbuckle system from there. The ApexAnchors payload anchor system bolts directly to the frame. This system requires no drilling in the frame.

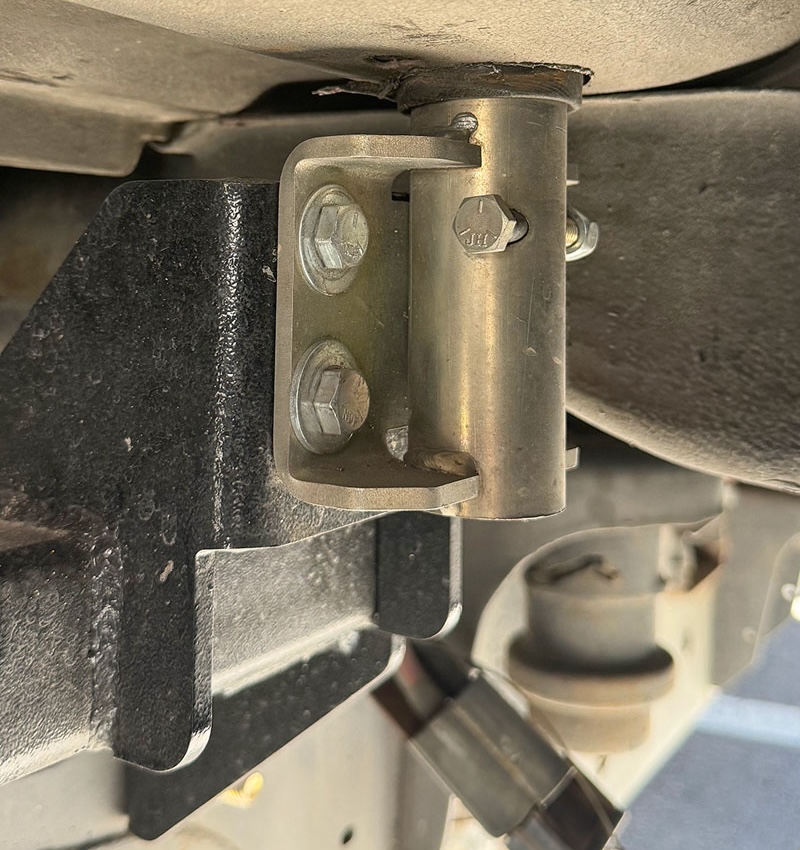

Above: The ApexAnchor tie-down payload anchor system installed under a truck

How is the ApexAnchors system installed?

Jay: Once the tie-down brackets are located under the truck, you use the brackets as a template. This determines where the holes need to be drilled through the truck bed. The holes are drilled with a two-inch hole saw. A rubber grommet finishes the hole to keep the truck bed looking clean. After that, you’re ready to finish the installation and load a camper.

Above: The ApexAnchor tie-down payload anchors recess when not in use

What are the performance advantages of the ApexAnchors system?

Jack: When you properly marry the camper to the frame and chassis of truck, it feels and performs as one vehicle going down the road. Where other tie-down and turnbuckle approaches allow the camper to shift, the Torklift ApexAnchors system locks it down. There’s a significant improvement when the camper is fixed to the truck frame.

Jay: The OEMs that have used the ApexAnchors system were skeptical at first. Now that they’ve been running around the country with the ApexAnchors system, they’re thrilled with how much better their rigs handle.

Above: A Cirrus 620 rig using the Torklift Apex internal tie-down and turnbuckle system

Will the product work with any truck camper designed to work with internal ratchet straps?

Jack: Yes.

Can someone with an older camper using internal ratchet straps upgrade to the product?

Kyler: Yes. We are developing a kit that will convert an existing ratchet strap system to the Torklift ApexAnchors system. It’s essentially a bolt-on adapter plate that’s installed where the ratchet strap system was mounted.

What does the ApexAnchors system weigh?

Jay: The installed system weight is thirty pounds. That’s not a lot when you’re talking about protecting the integrity of your camper. The ApexAnchors system also comes with Torklift’s Legendary Lifetime Warranty. That means buy it once and buy it for life.

Is the ApexAnchors system made at your Royal City Factory?

Kyler: Yes. The system was designed at our Retail Product Development Center in Kent, Washington, and is manufactured at our campus in Royal City, Washington.

What is the MSRP for the Apex Anchors and turnbuckles?

Kyler: Pricing is not yet set but, once it is available, it will be published on torkliftcentral.com.

When will these products be available?

Jay: The Toyota Tacoma kit will be available for pre-sale purchase in July followed by the Ford F-150. Then we’ll focus on the rest of the Ford F-series trucks and other brands.

Are there any additional Torklift announcements planned for 2024?

Jack: There are more Torklift products coming in 2024. We’re not ready to talk about them just yet, but we’ll announce them here in Truck Camper Magazine.

For more information about Torklift International, visit their website at torklift.com. Click here to request more information about Torklift products.