Greg Tucknies, Adventurer Manufacturing’s Sales and Marketing Manager, and Dave Frampton, Adventurer’s Product Development Manager, reveal Eagle Cap’s new nest and the first 2012 hatchlings.

Knowing the importance this story would have for Eagle Cap campers, we started our research by scouring EagleCapOwners.com, NATCOA.com, and RV.net in search of the questions and concerns the public had about the new Eagle Cap. We also directly contacted a number of Eagle Cap owners and talked to them at length about what they needed to know about the new Eagle Cap. From the forums, emails, and conversations, a core list of questions emerged.

Then we looked back at our own notes, photography, and experiences at the old Eagle Cap manufacturing facility in 2007 and 2010 and added a few questions of our own. Our goal was simple; a comprehensive re-launch story for Eagle Cap campers that would address all of the looming questions and concerns about the new Eagle Cap. Let no stone or fiberglass mold be unturned. Let’s nail it.

In the days leading up to the interview, we warned Greg Tucknies, Adventurer Manufacturing’s new Sales and Marketing Manager, “This will be a tough interview, but we have the questions people need answered”. Greg was actually very excited about this approach and welcomed the tough questions.

A few minutes into the interview we knew why. Greg and the Adventurer team had also done their homework, and then some. They had been reading the forums too. They’ve been listening to Eagle Cap owners closely. They understood the Eagle Cap product from the inside out. In short, they were ready.

ABOVE: One of the first campers down the line, an Eagle Cap 850

The following is an interview with Greg Tucknies, Adventurer Manufacturing’s Sales and Marketing Manager, and Dave Frampton, Adventurer’s Product Development Manager, on the new Eagle Cap.

TCM: Congratulations on your new position as National Sales Manager at Adventurer and Eagle Cap. Tell us about your history in the RV industry and how you came to work for Adventurer and Eagle Cap.

Greg: I started as an inside sales representative for Western RV/Alpenlite in October of 2000. Shortly there after, I was an outside sales representative under Burk Morgan, who hired me originally. I was with Western RV for seven years.

I left Western RV to work for Host RV as a sales representative for their truck campers and motorhomes. After two years with Host RV, I went to work at a local Yakima, Washington RV dealership in sales. Late last Fall, Burk gave me a call looking for someone to come help after the possible acquisition of Eagle Cap’s assets. When that acquisition came through, I was brought on board in mid-December.

TCM: We have a lot of questions for you about Eagle Cap, but can you first tell us about your RVing experience?

Greg: My whole life has had ties with RVing. I started tenting and then moved on to tent trailers, truck campers in my early married life, and then motorhomes. I’ve had a full regiment of RVs over the years. Of course, nothing is better than truck campers.

|

|

|

|

|

|

ABOVE: Eagle Cap campers coming down the new assembly line

TCM: That could not be a more true statement. Let’s talk about Eagle Cap. Adventurer has always been a price point, value oriented truck camper brand. Eagle Cap, on the other hand, has always been a high-end, premium oriented truck camper brand. This means the two company cultures have very different focuses and priorities. What are you doing to ensure that the brand, focus, and priority of Eagle Cap remains on the high-end premium market that made Eagle Cap a success?

Greg: Even before the Eagle Cap asset acquisition took place, the Adventurer management team understood that the Eagle Cap products were totally different than Adventurer products. Eagle Cap represents a totally different level of product with a totally different consumer following. If Eagle Cap had been the same as Adventurer, we would not have been interested in purchasing Eagle Cap’s assets.

With that understanding, our first goal for Eagle Cap was to create a separate and dedicated team and production line for Eagle Cap. Employees who work on the Adventurer production line do not work on the Eagle Cap production line, and vice versa. This will help to ensure that the two lines remain distinct.

There’s literally nothing else like Eagle Cap in the marketplace. You can’t just re-brand and re-badge a camper and make it an Eagle Cap.

|

|

|

ABOVE: Exterior photos of a 2012 Eagle Cap 850

TCM: Let’s talk about the specifics that made an Eagle Cap an Eagle Cap. Will the new Eagle Cap campers continue to feature molded fiberglass wall panels? Or, will they now have laminated luan backed filon walls like the Adventurer line?

Greg: I’ll let Dave Frampton, our Product Development Manager, answer that question.

Dave: The Eagle Cap line featured a high gloss gel coated side wall. We’re making the walls a bit differently, and better, as I will explain.

The old Eagle Cap side wall production started with a wet laid molded fiberglass wall that was then directly applied to an aluminum frame. When we studied this approach, we became concerned about the expansion and contraction of the different materials (fiberglass and aluminum) potentially causing a de-lamination and the weight of the resin required to make the direct lamination possible. At the same time, we wanted to maintain the very high gloss side walls that made an Eagle Cap distinct.

For the 2012 Eagle Cap line, we’re using a high gloss skin called Lamilux 4000. We’re applying the Lamilux 4000 to Azdel, a waterproof thermoplastic composite, using our in-house hot melt lamination system. The Lamilux 4000 and Azdel are then applied to our aluminum frame to create a side wall that is stronger and lighter than the old Eagle Cap side walls while maintaining Eagle Cap’s high gloss finish.

TCM: So the new Eagle Cap wall is not luan backed?

Dave: No, it’s backed by Azdel, a thermoplastic composite that’s lighter, stronger, and can’t physically rot. Azdel is a waterproof material and it bonds extremely well to aluminum.

TCM: Tell us a little more about Lamilux 4000. Does it come in rolls like filon?

Dave: Yes it does, but it’s not like what you’re used to with filon. Lamilux 4000 has an automotive gel finish. It’s similar to filon, but a much higher quality of product.

Keep in mind that the manufacturing process at the old Eagle Cap used a substantial amount of resin during their lamination process. It may be counter intuitive, but the sheer volume of resin used added a lot of weight to the old Eagle Cap wall. We saw a way to reduce the weight and increase the bond using the Azdale, Lamilux 4000, and our reactive hot melt lamination system.

TCM: Will the new Eagle Cap campers continue to feature molded fiberglass wrap around front and rear end caps?

Greg: Yes, they will. The front and rear molded wrap around fiberglass caps are one of the key features that make Eagle Cap campers unique. No other truck camper has front and rear wrap around fiberglass end caps. We purchased the end cap molds from the old Eagle Cap and are using the same front and rear caps in our 2012 Eagle Cap campers.

TCM: Have there been there any changes made to the quality of the fiberglass, resin, or high gloss gel coat for the molded fiberglass end caps?

Dave: The suppliers of the resin and gel coat have changed, but I believe the quality is higher. The company we’re using for the end caps is Miles Fiberglass & Composites in Portland, Oregon. Miles Fiberglass & Composites has produced fiberglass and composite parts for the RV industry for decades.

During my time at Western RV, we used Miles Fiberglass & Composites for Class A motorhome side walls. Here at Adventurer, we use Miles for front and rear end caps for our Class C motorhomes. We also use Miles Fiberglass & Composites for our Adventurer front nose caps. As a company, they build a very high quality product and do an excellent job with the glass. We are very comfortable using their products.

|

|

|

|

|

|

ABOVE: The overcab and kitchen areas of a 2012 Eagle Cap 850

TCM: Tell us about the changes to the adhesive used in the new Eagle Cap wall lamination?

Greg: We’re using our reactive hot melt system with pinch roll lamination. This is an important part of our Tru-Composite Construction (TCC), which is unique to our process. With our TCC technology, the Eagle Cap walls are now stronger, lighter, and more durable than they were before.

Dave: I’ve used both a reactive hot melt and pinch roll lamination system, and a resin and vacuum bonding lamination system. One key advantage with reactive hot melt over resin and vacuum bonding is 100% adhesive coverage. You can’t get 100% coverage with resin and vacuum bonding. The resin beads leaves spaces without adhesive leaving the possibility for de-lamination. This is not a problem with reactive hot melt and pinch roll system as you get 100% adhesive coverage.

TCM: Will the new Eagle Cap campers continue to feature two inch walls?

Greg: Absolutely. That is an important part of the structure Eagle Cap is known for. We are using the same framing and two inch walls all the way through.

TCM: Eagle Cap sealed their roof with Sikaflex 715. When we were at the factory in July of last year, they were also testing Sikaflex for the side wall seals. Has the new production line adapted Sikaflex for the camper seals?

Greg: We’re using the same Sikaflex sealant on the Eagle Cap line. Again, we want to make sure everything is the same or better on the new Eagle Cap line.

|

|

|

ABOVE: The Eagle Cap cabinets for 2012 will be made out of a light cherry wood

TCM: The interior of Eagle Cap campers featured solid hardwood cabinetry. Do the new Eagle Cap campers feature solid hardwood cabinetry?

Greg: Yes, they do. The new 2012 Eagle Cap models feature a light cherry wood with a rich and elegant look. It really matches the high quality of the Eagle Cap line. People who have visited the plant are excited when they see it. Dealers have visited the Eagle Cap line during production and are impressed with it. It really raises the interior look.

|

|

|

ABOVE: The fiberglass bathroom in a 2012 Eagle Cap 850

TCM: Eagle Cap also manufactured their own one piece molded fiberglass bathroom stalls. Will those be retained in the new Eagle Cap campers?

Greg: We purchased all of the molds and shower stalls from the old Eagle Cap. Anything that was fiberglass in the old Eagle Cap we’re going to keep fiberglass in the new Eagle Cap. That’s what Miles Fiberglass & Composites is doing for us.

ABOVE: The granite coat table in the dinette of a 2012 Eagle Cap 850

TCM: Another important in-house manufactured Eagle Cap feature was their light weight granite coat counter tops. Will the new Eagle Cap campers feature the granite coat fiberglass table and counter tops?

Greg: Yes. The granite coat counter tops and tables are unique to Eagle Cap. Other manufacturers have tried to copy them, but have failed. They’re a really nice granite gel coat counter top and table top, that really add to the interior elegance and quality of an Eagle Cap.

Again, this is why we’re working with Miles Fiberglass & Composites. We’ve long understood that if an outside company specializes in a product, it’s much better for quality control to have that outside company provide that product rather than attempt to do it in house. We’ll get a consistent quality from Miles that we couldn’t match in house.

ABOVE: An overall view of a 2012 Eagle Cap 850

TCM: Are you building the same floor plans as the old Eagle Cap or are you working on new floor plans?

Greg: We will be building the same floor plans as the old Eagle Cap with the exception of the 711, 811, and 800, which will be discontinued. Dealer and customer orders will dictate our model production runs. We’ll let the dealers and the public tell us what they want.

We are making a change on the 1160 which is to adopt the basement style of the 1165 triple-slide. Now both the 1160 and the 1165 will have a floor that is over the rails of the truck allowing for more storage, wider body and more floor space.

TCM: So you’re going to continue the 1165 triple slide?

Greg: Yes. My experience with Host RV gives me a unique perspective on the triple slide product. If there’s demand for a triple or double slide camper, we’ll be in the market for it. And we have an excellent engineering team with Dave Frampton and Dave Catron.

TCM: Are you using the previous schematics and plans from the old Eagle Cap, or are you drawing new schematics and plans?

Dave: We are going through and redrawing each camper into the drawing format our production team understands. We’re also adapting the plans for the manufacturing processes we use. And wherever there is an opportunity to drive out weight or make the manufacturing process more efficient, we’re making those changes as well.

TCM: Can you give us some examples of where you’ve been able to save weight or make the manufacturing process more efficient?

Dave: One example being more efficient is in the consistency of the length of cut materials. If you cut your materials correctly, you can save time, money, and material and pass those savings onto the consumer. There will be many more examples as the models debut.

TCM: Speaking of debuting new models, what is the plan for model roll out? Will we see more Eagle Cap camper models this year?

Greg: We are building Eagle Cap campers in runs of four. At the old Eagle Cap, they would build one-off campers with one 950 on the line, followed by an 850 on the line, followed by an 1160 on the line, and so forth. By building in runs of four, we’ll be able to improve quality, production efficiency, and reduce costs.

The first run of four 2012 Eagle Cap campers are 850s. Then we will make two runs of 995s, followed by 950s, 850s, and 1160s. The last model scheduled is the 1050s.

TCM: Based on changes to materials, construction, and appliances, should we expect to see a significant difference in the weight of the new Eagle Caps?

Greg: We’re expecting to see a weight reduction, but won’t know how much until each model is completed. Dave and Dave are on a mission to reduce weight in the Adventurer and Eagle Cap lines but we won’t know the real numbers until the campers are on our scales.

|

|

|

ABOVE: A 2012 Eagle Cap 850 being weighed at the factory

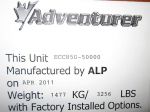

TCM: Will each Eagle Cap camper be individually weighed and have that weight recorded inside of each camper?

Greg: Yes, we will weigh every unit. That’s an important priority for Adventurer as a company and for the products we produce, including Eagle Cap. It’s vital for the consumer to safely match their camper to the correct truck. The weight of our Adventurer and Eagle Cap campers is accurately published inside an interior cabinet.

One thing to consider with the weight of the new Eagle Cap campers is that we have added a number of standard features that were previously options. What we found is that there was a long list of options that were being added on 99.9% of all Eagle Caps. Unfortunately, this skewed the base dry weight as it did not reflect this common list of options. The good news for the consumer is that you’ll have a more accurate dry weight with the new Eagle Cap models as these options are now standard.

|

|

|

ABOVE: The Dream Dinette table comes standard in 2012 Eagle Cap campers

TCM: Can you give us some specific examples of things that were optional that are now standard?

Greg: The assist handle, pre-wire for solar, LED interior lights, full extension ball bearing roller guides, and the dream dinette table. There’s more, but I’ll wait until we have our new materials together to make that announcement.

TCM: What’s the situation with the previously existing Eagle Cap dealers?

Greg: When I started at Adventurer, I spent two or three months contacting the Eagle Cap dealers and talking to them about what we were doing with Eagle Cap. There were rumors circulating that we were not going to build Eagle Cap and some dealers were actually shocked that we were actually going to build them.

As the third version of Eagle Cap, the dealers needed to know that we were stable as a company and dedicated to the brand. Once we got past that, most of the dealers have stayed with us. Some who initially said no are now coming back now that they are hearing from other dealers who have visited our factory. We will be looking for more dealers as we grow, but right now our goal is to take care of our current dealers.

TCM: Have you been honoring previous Eagle Cap warranties through your dealer networks?

Greg: We have been continually working with retail customers and working on issues with previous Eagle Cap product. We are not legally bound to provide the warranty care, but we want to provide good will and assistance with existing Eagle Cap owners.

ABOVE: The Eagle Cap logo has not changed

TCM: Speaking of warranty, what will the warranty be for the new Eagle Cap campers?

Greg: 2012 Eagle Cap campers will have the same two year warranty the old Eagle Cap campers offered. We may look at offering a longer warranty in the future, but we decided not to make any changes at this time.

We also didn’t change the exterior graphics on the campers. We really want the same Eagle Cap look, feel, and experience. As the saying goes, “If it ain’t broke, don’t fix it”.

TCM: When can we expect to see new Eagle Cap campers at dealers?

Greg: The first shipment of 2012 Eagle Caps is going out this week to dealers who have ordered early. We also have several new Eagle Cap customers who bought their campers after we talked to them on the phone. They are very excited.

TCM: How about the price of the new Eagle Cap campers. Is the price going up, down, or will it be the same?

Greg: Actually, the price has come down about $600 per unit. Our team did a lot of research on the products that we’re purchasing to build the camper and has been able to drive cost out. We also found cost savings in the production and labor time needed to build each camper.

TCM: Can you save money by buying product and materials for both the Adventurer and Eagle Cap line at the same time?

Greg: In some cases, we’re able to buy material or appliances in quantity with the buying power of Adventurer. For example, water pumps and water heaters cost us less because we buy in quantity. The biggest price change for Eagle Cap is in the cost of options, which have fallen substantially.

TCM: Is there anything else you would like existing and potential Eagle Cap owners to know about the new Eagle Cap?

Greg: We looked long and hard at Eagle Cap before making the acquisition of the Eagle Cap assets. We see Eagle Cap as a long term opportunity. I believe we’ve now been through the tough times and Eagle Cap will be stronger and better than ever. I’m very excited about the line. There are more plans on the drawing board and we are very committed to the Eagle Cap brand.

TCM: You mentioned several times during the interview that dealers have come by to see the new Eagle Cap production line. Can our readers make an appointment to see the new Eagle Cap production line as well?

Greg: Absolutely. We offer tours. We do not have scheduled times so please call ahead and we’ll take you through to see the Adventurer and Eagle Cap production lines.

TCM: We need to schedule a tour ourselves. Thanks for sharing the news and please keep us up to date on the latest at Eagle Cap.

Greg: We will.