Continuing the “Never Seen That” tour, TCM visits Northern Lite’s new factory in Kelowna, British Columbia and discovers something completely different, and somehow quite familiar.

After the devastating fire that destroyed the Northern Lite factory in February of 2014, the courageous announcement to rebuild the following April, and the almost unbelievable news in January that they were back in production, we had to go see the new Northern Lite campers being built for ourselves.

Welcome to the next installment of our 2015 “Never Seen That” tour. This time we reach the furthest most point on our tour and, by far, our most anticipated stop, Northern Lite in Kelowna, British Columbia.

|

|

|

Even though we knew about the devastating fire and rebuilding process, it was still incredible to see a brand new building where the old Northern Lite factory had stood. It was also a moment of tremendous pride to see this gleaming structure with its defiant Northern Lite logo and geese, modern windows, and bay doors.

Walking into the plant we were instantly struck with the wide open spaces, brighter lighting, and immaculate organization. Yet, somehow, everything was also familiar. The production line is exactly where it was before. The wood and cabinet shops are exactly where they were before. Even the fiberglass shop is essentially where it was before.

Even the upstairs offices were exactly where they were before. In short, everything was new, and yet – with some important differences – right where it had been.

During the design, construction, and move-in, the production team was consulted for ideas to improve efficiency, productivity, and workplace comfort. In essence, what you’re seeing is a direct result of the Northern Lite management and production team coming together to make the ultimate Northern Lite factory. They had to start from scratch, so they had the unique opportunity to approach everything fresh.

|

|

|

The new break room is bright with daylight and features two HD televisions, two refrigerators, seven microwaves, thirty-four lockers, and plenty of tables and chairs. While work is never going to be a vacation, it’s clear that the Northern Lite management team did what they could to improve the working conditions at Northern Lite.

If you were to step inside the new Northern Lite factory, walk all the way to the back of the building, and turn right, you would walk into Northern Lite’s new fiberglass booth.

The new fiberglass booth is significantly bigger allowing Northern Lite to have two top and bottom mold sets inside the building at any given time. Want to know how Northern Lite is dramatically increasing its production capacity while maintaining its legendary quality? Start here.

We can’t report that Northern Lite upgraded its fiberglass and gel coat application equipment because they already had the best fiberglass and gel coat application equipment equipment before the fire. Now they have new versions of what they had before; essentially the lowest emission, highest quality fiberglass chop guns and gel coat applicators on the market.

Keith also explained to us the lengths Northern Lite goes to get the highest quality gel coat. While the details of that process are proprietary, suffice it to say that Northern Lite doesn’t go down to the local industrial supply store and pick up some gel coat. To get exactly the right gel coat color, and exactly the right durability, Northern Lite has a very carefully selected gel coat quality, gel coat vendor, and gel coat purchasing process. For such a critical element of the Northern Lite product, nothing is left to chance.

Lest we forget, not only is this the new fiberglass shop, but those are also the new 3D AutoCAD designed molds. Via Keith’s YouTube video, we watched the mold plugs being carved by a five axis CNC machine in the United States last July. And here they are, in regular production, producing Northern Lite fiberglass shells like clockwork. Seeing this in person was beautiful from so many perspectives.

Before a fiberglass shell is produced, the insulation sections that make up the interior insulation for a Northern Lite truck camper are brought to the fiberglass booth. These will be installed by the fiberglass team like puzzle pieces.

This image shows the floor insulation ready to be integrated into a completed shell. The blue color is an adhesive applied in a room adjacent to the fiberglass booth.

We have seen at least a dozen fiberglass molds pulled at Northern Lite, but it never fails to be a wow moment. In this photograph you can see the new higher capacity 3,000 pound hoists that lift the bottom shells out of their molds.

Looking like the Starship Enterprise ready to go into warp, the bottom shell is then lowered onto a rolling platform.

The cradles that hold the molds are also new and improved. The old cradles required a worker to literally climb up and hang on the outside of the molds in order to get the molds to turn. With the new cradles, the molds turn with a cordless drill. This speeds the process and reduces physical stress on the fiberglass production team.

|

|

|

After the lower mold is released and rolled into the marriage room next door, the upper shell is released from its mold by Blaine and Nick. This time the mold is turned face down onto a rolling platform and the mold itself is raised with the aforementioned hoist to release the shell.

With the upper shell now released, it too is rolled into the marriage room through a bay door. In the third photo above, you can see the upper and lower molds in the marriage room. The bay door in the background is the same door the two shells just passed through.

|

|

|

At the old factory, Northern Lite upper and lower fiberglass shells were trimmed and married outside and then wheeled into a finishing room. In the new building, not only is the marriage room right next door to the fiberglass shop, but it also has enough space to hold at least two units. This new marriage room is where the shells are trimmed, brought together with a hoist, and prepared for the production line.

Once completed, the two-piece molded fiberglass body is wheeled onto the production line through another bay door.

With the previous building, Northern Lite married the top and bottom clam shells outside, brought the wedded shells back inside, and then wheeled them back out again to enter the main production line. Not only was this inefficient, but it also meant exposing Northern Lite team members to hot and cold weather, and various forms of precipitation.

With the new building, campers don’t leave the building until final finishing rolls them out the front bay doors. The fiberglass shop, marriage chapel, and production line are still separated by bay doors, but those doors are now inside. When I talked to the team about what this meant on a day-to-day basis, they raved about being more comfortable, and having increased productivity.

Sometimes simple things can make a big difference. Take the taller and higher capacity shelving found throughout the new Northern Lite factory. In the wood and cabinetry shops, the new shelving units put the raw materials closer to where they’re needed, allows for improved organization, and increases the overall material storage capacity. All of this helps to improve efficiency and drives down costs.

A few feet from where the above photograph was taken, wood is cut by Michael to the lengths needed by the cabinet shop.

When the cut wood materials are ready, they are placed into marked bins immediately next to the wood shop. On the other side of these storage bins is the cabinetry shop.

During our initial walk through the building, Keith pointed out how there are additional work stations and spaces ready for future growth. For example, the table and counter top production area has ready-to-go stations for more team members.

|

|

|

The wider aisles and larger production tables in the cabinetry shop better accommodate the new cabinetry jigs to increase production efficiency and quality.

The results of all this efficiency are everywhere. Here you see freshly constructed cabinet frames ready for finishing.

In the articles following the fire, Keith Donkin, Northern Lite’s General Manager, talked about how his team recreated the destroyed jigs necessary to produce Northern Lite truck campers. Perhaps what’s most amazing is that these jigs were recreated as much from the team’s memory as the reverse engineering from surviving Northern Lite units.

Now recreating a cabinet jig is one challenge, but recreating a 110-volt and 12-volt wiring harness jig is quite another. After all, a wiring harness contains essentially all of the required 110-volt and 12-volt wiring for an entire truck camper; stem to stern. Let’s just say that one does not recreate a new camper wiring harness jig in an afternoon.

As Keith also explained to us, the team members were given latitude to make improvements not only to their tools and work environment, but their jigs as well.

Around the bend from the new wiring harness jig is where Northern Lite battery boxes are assembled by Brian. Everywhere we looked, the carefully thought out utilization of space and the resulting productivity improvements were obvious.

Northern Lite truck camper builds still begin with a wholesale order sheet sent in, usually via fax, from a Northern Lite dealer. Northern Lite dealers initiate these orders to either have Northern Lite truck campers in stock at their dealership, or to fill a specific customer order. Either way, a new camper begins with a wholesale order sheet.

|

|

|

Once completed and approved by management, these wholesale order sheets are handed to Chuck, Operations Manager. From his office just off the main production floor, Chuck manages the production workflow ensuring that the required man power and materials are in place and production stays on schedule.

When camper shells emerge from the fiberglass shop as finished bodies, these wholesale order sheets, along with time tracking sheets, are taped onto the back of the campers. From that point forward, the wholesale order forms guide the production process. Any non-standard detail about a specific order will be highlighted in pink to alert the production team about that variance.

At the end of the line, final finishing assembles the wholesale order sheets and time sheets back onto a clipboard to be turned into Chuck and senior management. Then the process starts all over again.

Production at most truck camper factories is set to a very tight schedule. The production team arrives, works, takes breaks, takes lunch, and leaves at specific times. Walk the factory when the production team is on break and it’s a ghost town. Then the get-back-to-work buzzer goes, and everyone is back on task almost instantly.

The exterior LED lights on this 10-2 EX were being checked when the break buzzer blew. Notice the test controller on the step waiting for the test to continue.

Producing a Northern Lite is like building a ship in a bottle. The exterior top and bottom fiberglass molds are, as you saw above, literally married first, and then the interior of the camper is built inside that completed fiberglass structure. Once the two shells are married, everything must be brought in through the back door.

Well, that’s not exactly accurate. The fiberglass wet bath components are placed inside the lower fiberglass camper shell prior to marriage with the upper shell. There’s no other way they could get the bathroom in as it’s too big to fit through the door.

So what’s more challenging than building a ship in a bottle? Building a fiberglass bathroom in a ship in a bottle. In this photograph you see Greg installing the plumbing and toilet in a 10-2 wet bath mold. Take it from me, this was not an easy task.

|

|

|

With the kind of seek and destroy focus one usually reserves at the dessert table at a truck camper rally, Mike is on a never-ending mission to find and repair gelcoat imperfections. Throughout our two day tour, we saw Mike working on various Northern Lite units until their gelcoat exteriors were perfect.

Most of the imperfections he was working were all but invisible until he pointed them out, and even then they appeared more like a blemish than anything one would consider a problem. Of course we didn’t say a word and enjoyed watching his unmistakable focus on perfection. Just look at the intensity in which he tackles his job.

Now this is how it’s done. We recently installed a roof top air conditioner and the process of getting the unit on the roof wasn’t difficult, but it certainly wasn’t easy. Of course, we didn’t have a Genie QuickStock man lift handy like Shane and Russell at Northern Lite.

This is the same man lift that I used to get the aerial shots of the factory. It not only lifts you fifteen feet in the air, but it also drives around with a simple joystick control. I have no idea why, or what I’d do with it, but I want one.

At the same station where the air conditioner is being installed, Mel is busy installing the Sapele wood cabinetry and trim work inside the unit.

Another remarkable take-away from our visit was the resilience of the Northern Lite team. While many of them commented on the challenges they faced during the post-fire recovery, they were very positive and thoroughly engaged in their work.

There’s a real sense that the team has put the fire in the past, and is enjoying the sense of renewed purpose and momentum the new factory has brought.

All of the factory equipment is not only new, but improved, multiplied, and, where it would help increase efficiency, moved. For example, there are now multiple new saw stations along the production line exactly where the team needs them. This shortens the distance a team member might need to walk, reduces or eliminates the time they might need to wait, and helps to keep them in the flow of their work.

Taking a step back from the factory improvements, the production steps involved in building a Northern Lite truck camper remain mostly unchanged. Decals – pronounced “deh-culs” in Canadian, “dee-cals” in United States-ian – are still carefully applied by Don by hand.

|

|

|

Towards the end of the production line, a room full of cushion sets and mattresses waits for final finishing. Not only are the cushion sets well marked and organized, but there were about two dozen camper sets ready to go. In fact, everywhere we looked Northern Lite was well organized and well stocked for steady production. This is a very strong sign that management, purchasing, and Northern Lite’s vendors are working well together to ensure smooth and efficient production.

The increased floor space in the new factory really makes a difference in every step of the production line process, including installing an awning. Look closely at this image and notice the carpeted ladders are safely positioned, the lighting is excellent, and Troy and Mike are free to focus on the task in front of them.

At final finishing, the Northern Lite team puts the finishing touches on a unit while inspecting every facet of the workmanship and quality of the unit. One final finishing step that surprised us was staining the Sapele cabover entry trim. According to Gail (above left), applying the stain earlier in production occasionally caused damage to the finish, so they simply moved stain to final finishing.

To test the integrity of the exterior seals, Northern Lite pressurizes the inside of their units with a SealTech machine at the final finishing. With all windows, vents, and the entry door closed, a SealTech machine pressurizes the inside of a truck camper forcing air out of any possible exterior seal breaks. These leaks are then revealed by spraying soapy water on the seals and looking for bubbles. It’s a simple, and ingenious way to find broken seals.

|

|

|

After watching Troy spray soapy water for several minutes without a single leak revealing bubble, I asked, “Do you ever find a leak?”

“Not often” he replied, “But we want to catch any leaks now before they leave the factory.”

I watched for another five minutes as he completed the front, sides, back, and undersides of the camper without a single bubble.

“Looks good to me. No leaks, just how we like it.”

Now I have watched at least a dozen SealTech sessions in my lifetime, including one on our own camper. I have never seen zero bubbles, until now. Very impressive.

|

|

|

Northern Lite had something we had never seen at the end of their production line, a wireless Intercomp SW-650 scale system ($1,650). Having set up our share of wired Intercomp scales at factories and dealerships across the continent, it was awesome to see the wireless system work beautifully.

Why every truck camper manufacturer and dealership doesn’t at least have a wired Intercomp SW500 E-Z scale ($1,100) in regular service is beyond us. The wireless feature only makes using this highly accurate system that much easier and faster.

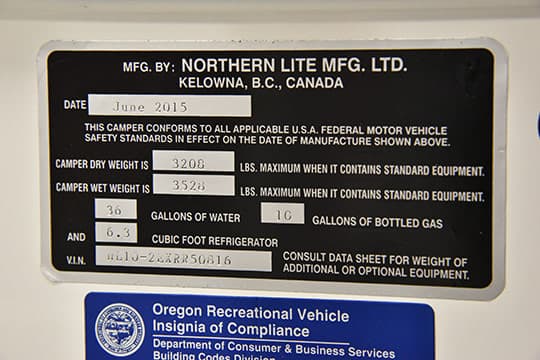

While we watched, Troy placed the four scale pads under the Happijac jacks and raised the camper off its wheeled production line platform. In seconds the Intercomp revealed a total dry weight for this 2016 Northern Lite 10-2 EX RR dry bath; 3,361 pounds.

On the back of this same camper, the weight sticker declares the dry weight at 3,208 pounds. Any way you slice it, this 2016 Northern Lite 10-2 EX RR is one fully-featured luxury hard side long bed truck camper that could work within the payload capacity of a properly specified one-ton, long bed, single rear wheel truck.

As we prepared to leave, so did a fresh batch of 2016 Northern Lite truck campers. The camper we had seen completed and weighed over the course of two days was on the load.

Wrap It Up

The quality of Northern Lite truck campers is often chalked up to their dedication to fiberglass clamshell construction, or their focus on a limited number non-slide hard-side truck camper floor plans, or their steady year-to-year refinement. Of course it’s all of these elements, but that’s not what really makes Northern Lite an industry standard in quality.

The real secret in Northern Lite’s sauce is their team. After this last visit, we have visited Northern Lite three times; 2007, 2010, and 2015. Almost without exception, the production team is unchanged in those eight years. The same craftsmen and women are at the same posts getting a little better at what they do every day.

That’s why the big news about Northern Lite’s new factory has nothing to do with the new factory. The big news is that they were able to retain their production team; from the fiberglass shop, to final finishing, and every station in between. If that doesn’t speak directly to the quality and dedication of Northern Lite, nothing does.

To learn more about Northern Lite truck campers, visit their website at www.northern-lite.com.