Truck Camper Magazine goes inside Lance Campers in Lancaster, California for an unrestricted multi-day look at their factory, teams, and processes. Under new leadership, Lance is reclaiming its legacy and charging into an ambitious new future. New Lance teasers ahead!

When news broke of a change in Lance Camper’s ownership this past June, a visit to Lancaster became a top 2025 TCM priority. Okay, Cosmo cat, pack your treats and laser pointer. We’re going on a road trip!

Exactly two months later, we arrived at the main Lance building and parked our rig under an extended overhang. With our solar panels shaded and temperatures pushing 100 degrees, we had no choice but to plug into 30 amps. Shore power activated, we cranked the AC for our feline CEO, and entered the plant.

We spent the next two days with unrestricted access to both the lamination and main production buildings. Lance even provided us with a truck to drive between the two facilities at our convenience and a security card. They wanted us to see their factory, team, facility, and process as they were, and report what we found to you. That’s exactly what follows.

We began our tour of Lance Campers in their lamination building (shown above), a short drive from their main assembly plant. This 60,000-square-foot, climate-controlled facility handles the CNC cutting of aluminum, foam insulation, and camper walls, the welding of Lance Lock aluminum frames, and the lamination of walls, floors, and roofs for Lance campers and trailers. It’s a busy building.

Funny enough, the first part of this enormous building we were taken to was a relatively small room with a climate control system (shown above). This system monitors the building to maintain the precise temperature, humidity, and air quality required for maximum lamination adhesive bond performance and strength.

Despite the oven-like temperatures outside—like 104 with 20 percent humidity—Lance’s lamination building was about 82 degrees with 54 percent humidity. The contrast was remarkable.

To further enhance lamination strength, Lance brings the raw luan plywood, Azdel composite paneling, aluminum tubing, closed-cell foam insulation, and lamination adhesive inside the climate-controlled building for a minimum of 48 hours. This acclimation ensures the materials are all the same temperature before lamination, a crucial practice for long-term bond quality.

Throughout the lamination area, sensors constantly track temperature and humidity. When needed, ceiling nozzles release a fine mist of purified water (what I’m pointing to) to keep the air cool and balanced. We had witnessed this technique in lamination facilities before, but the scale of Lance’s lamination building took it to a new level.

As President Ronald Reagan most famously said, “Trust, but verify.” The Lance team keeps careful tabs on the climate-control system by logging the exact temperature and humidity every two hours.

At the opposite end of the lamination building, the lamination team was running materials through an adhesive applicator, assembling walls, and pushing the assembly through a pinch roller.

This is always a fascinating dance to watch as it requires precise adhesive temperatures and application, physically feeding and pulling the materials through the applicator without touching the applied adhesive, placing the adhesive-coated materials together perfectly onto a lamination table, and then feeding it all through the pinch roller before the adhesive starts to cure. If I tried it, I’d end up permanently adhered to the floor of the Lance factory.

Lance Campers are framed with a combination of aluminum tubing and proprietary interlocking extrusions called Lance Lock. The aluminum tubing and proprietary Lance extrusions are CNC cut for precision and efficiency.

After CNC cutting, aluminum sections—and the majority of parts at Lance Campers—are individually labeled, indicating the part, model, and batch number. This allows everything going into a Lance Camper to be tightly tracked for inventory and quality control.

Just a few steps from the aluminum CNC machine were sample sections of Lance Lock, the proprietary aluminum extrusion system first introduced with the Max Series in 2005. The system includes more than a dozen interlocking extrusions, each designed for specific structural roles. The two extrusions shown above are used in the cabover and front wall to add strength.

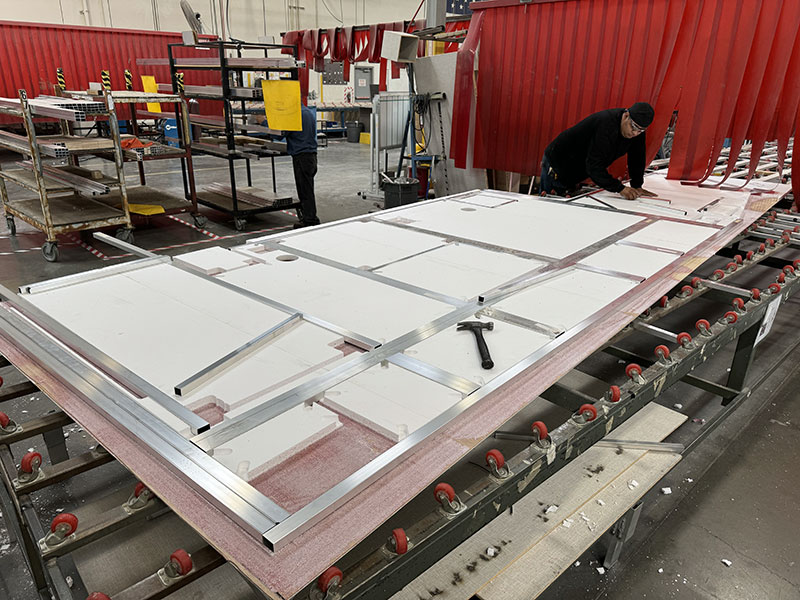

Multiple CNC machines were running at once in Lance’s lamination building. In this photo, a closed-cell foam insulation panel is being precisely routed. The clever part is that Lance uses the foam panel itself as the jig, welding the aluminum frame directly into it instead of building separate jigs and inserting the foam afterward. This approach streamlines the process and cuts several production steps.

Here, a welding team member is inserting aluminum framing into the CNC-routed insulation for a camper sidewall. This was like watching a puzzle being put together as the labeled aluminum sections could only go where the design intended. As avid puzzle fans, it was all we could do not to pick up an aluminum tube and help out. Start with the edges!

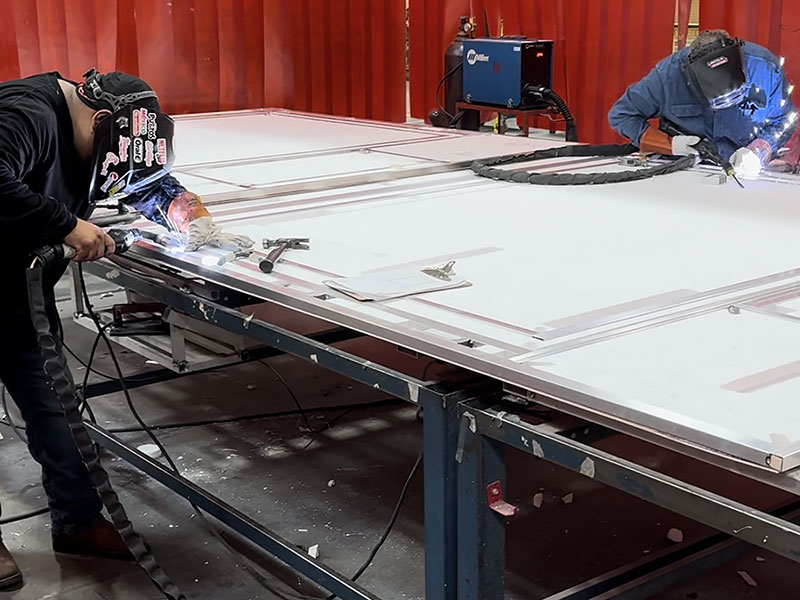

Once the puzzle was completed, the side wall was rolled through a red welding curtain to be welded. It’s a bit hard to see in the images, but the CNC machine cuts pockets into the white insulation precisely where the welders need to access the aluminum intersections. This is how meticulous CAD design, CNC routing, and precision welding efficiently meet in a symphony of manufacturing.

After the welding team completes a frame, the wall and frame are rolled out of the curtained welding area. On the other side, a team removes the frame and cleans the laminated foam insulation. Any foam in the frame channels that was not removed by the CNC machine or was charred by the welding process is then scraped away. Once this process is completed, the frame is placed back into the wall. It’s a very snug fit.

Certain complex or model-specific parts are built by dedicated team members before joining the main production line. Here, a Lance 1172 inside step assembly is being completed.

Final roof assembly is also handled by a separate team. While we observed, the roof team was installing 110 and 12-volt electrical wiring for a fan, lighting, and a roof-mounted air conditioner.

Lance Campers pointed out that the wiring was all individually color-coded so it could be traced throughout the unit. This can be especially important when attempting to track down an electrical issue or installing a new component in the camper.

The final products of the lamination building are completed floors, roofs, and sidewalls. These are manufactured in runs and delivered to the assembly building just in time for the production line. Speaking of the production line, let’s go to the main building and see some campers coming together.

We first pulled into the circle of the main Lance Camper factory in 2005, two years before launching Truck Camper Magazine. We toured the factory, happened to meet the marketing manager, and the rest is history.

Twenty years later, the main Lance Camper factory remains an impressive sight. Few factories in the truck camper or RV world have anything approaching this kind of presentation. Welcome to Lance. Buckle up, buttercup!

Once you’re inside the 141,000 square foot main factory, there’s a lot to absorb. For example, Lance has pioneered many industry-leading high-quality material and manufacturing standards over the years. Here you see the copper pipe Lance uses for its propane systems.

Lance prefers copper to black iron or reinforced synthetic lines for its flexibility, resistance to corrosion, durability, and long lifespan. That stated, copper lines are expensive and require a dedicated craftsman to produce. This guy made copper propane lines look like works of art.

The scale of the main factory allows for the required manufacturing processes to be given ample space and to set that space for maximum efficiency. Here you see an area dedicated to solar panel prep. You’ll notice nearly everything outside the main production line has a dedicated and maximized space.

Lance had even more CNC machines running full-tilt in the main building. This C.R. Onsrud CNC machine was routing window valance components.

About fifty feet from the CNC machine, a dedicated team was assembling valances. See that swooping shape in the valances? That’s courtesy of CAD and CNC.

This is a good moment to highlight that Lance builds nearly everything in-house. While many companies outsource CNC-cut parts or contract out components like valances, Lance keeps these processes under its own roof. The upfront costs are higher, but the benefits in quality and revision control are hard to match. And, over time, in-house production can help drive costs down.

This is another great example of Lance building as much as possible in-house. Where other manufacturers will outsource their drawers (they can be complex to make), Lance has the required CAD, CNC, and experience to make their own. And wow, do they make a lot of drawers for their truck camper and travel trailer lines.

Lance Camper basements always start the same way—upside down. This is the exact spot where we saw upside-down Lance basements being manufactured in 2005. And again, when we visited in 2007. And again in 2010. You get the idea. If you have a Lance truck camper, it very likely started in this exact spot—upside down!

A few feet from the upside-down basement, we watched the first quality control checkpoint on the camper production line. Of course, this isn’t actually the first quality control inspection. Long before a basement takes shape, every laminated wall, roof, and component is inspected and signed off.

If anything is found to be not up to Lance standards, Lance’s quality control process allows them to trace that issue back to the process or source. And with that information, management and production can take immediate action.

Against the far wall is where truck camper manufacturing becomes a straight shot—down the production line, out a tall bay door, into the storage yard, out to a Lance dealer, onto your truck, and off you go to Yosemite National Park. Isn’t that the point of all this?

In this photo, the Lance Camper has been flipped upright, showing the aluminum-framed and laminated floor we saw produced in the lamination building. On top of that floor goes the CNC cut interior walls and—as you can see sprawled across the surface of this unit—the PEX plumbing harness and electrical wiring.

Lance truck campers not only start upside down, but they’re also built inside-out, and from the ground up. Here you can see this inside-out and ground-up approach in action as the CNC cut walls and cabinetry have been added—often as pre-assembled modules—to erect the interior height of the camper. At the same time, the PEX plumbing and wiring are being interwoven according to CAD plans.

One of Lance’s core design principles is that their campers are engineered to prevent assembly errors. Thanks to the precision of CAD and CNC, every part, sub-assembly, and unit is designed to fit only one way. Any deviation is like forcing a round peg into a square hole. This philosophy has guided Lance’s manufacturing since CAD and CNC revolutionized the company in the late 2000s.

Once the interior walls and cabinetry are completed, the aluminum-framed and laminated walls are installed. This involves a crane slightly out of picture, and three team members to carefully guide the sidewall into position.

Check out how this sidewall already has its decals installed. This showcases the kind of progressive design and manufacturing approach that allows Lance to continuously improve efficiency and drive down cost.

With the sidewalls and rear wall installed, this Lance 1062 is being prepared to receive its dual slide-outs. This means installing flexible wiper and bulb seals to prevent moisture and airflow into the unit.

Have you ever wondered how a slide-out is installed in a camper? Here’s how it works: a dedicated team assembles the slide-out off the production line, then brings it over on a purpose-built cradle where a crane lifts it into place. The critical step is alignment. The team must carefully guide the room into the opening by eye. In this case, a crew member inside the 1062 handled the final adjustment. As you’d expect, they nailed it. These guys are pros.

Just off the camper production line, we found a cart full of camper bumpers being prepped for installation. These bumpers are manufactured by Torklift International at their Royal City, Washington factory.

Note how the bumpers incorporate the rear tail lights so that holes don’t need to be cut into the rear wall of a Lance Camper. Less holes, less things to seal, and less chances for a leak.

In mid-2012, Lance Campers debuted a one-piece TPO (Thermoplastic Polyolefin) front nose cap. The nose cap was designed by then Product Development Manager, Les Fowler, and his team to improve aerodynamics and durability while enhancing the front nose weather seal.

The nose cap also looked cool, giving the 2013 Lance Camper line (and every model year thereafter) a sleeker and more aggressive profile. Thirteen years later, the Lance front nose cap has become a signature element for Lance truck campers.

The above photo was taken just outside the main building in an area where Lance front nose caps are carefully cleaned and inspected (they’re made locally but not in-house). If there are any blemishes, the nose cap is sanded, painted and polished to bring it up to Lance standards. Once it’s approved, it heads to the production line for installation.

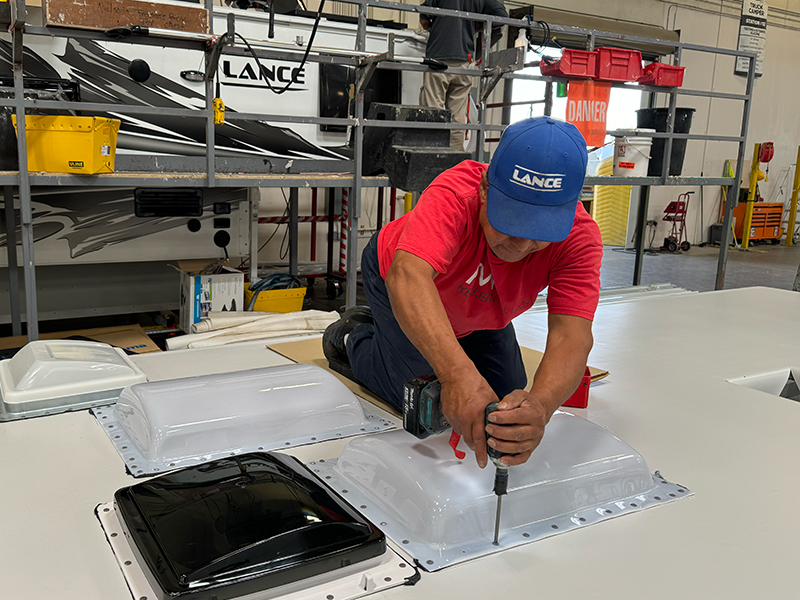

Like the slide-out rooms, roofs are manufactured and prepared by separate teams before being brought to the production line.

In the above photo, the roof vents and fans are being screwed into a new roof. After the roof is installed on a camper, the base of these features and the screws will be covered by Dicor self-leveling lap sealant.

Once more, a crane and gantry are employed to bring the aluminum-framed and laminated roof to the production line. There, the roof is lifted to a dedicated roof team. The roof team works on elevated platforms that envelop a truck camper during the install process.

Before the roof is secured to the camper body, the roof team integrates the roof electrical system—specifically the wiring for the lights, fans, air conditioner, and solar panels—to the main camper electrical system. This step is another reason why Lance meticulously color codes its camper wiring.

With the wiring completed, the roof is guided into position. This is a three person procedure to make sure this roof lands perfectly.

Here we see the Dicor self-leveling sealant starting to be applied. Moments later, Dicor would be applied around the antenna in the foreground and every other screwed-down roof feature.

Most truck campers rely on Dicor to seal their roofs. With a little care, it can protect your rig for decades. A quick annual inspection is all it takes. First, look for cracks, peeling, or gaps. If you see any, remove the old Dicor and replace it. Another important test is to press the Dicor to check its flexibility. If you leave an indentation, the Dicor is still flexible and doing its job. If it feels firm, it has probably dried out and needs to be replaced. Keep up this simple routine and your roof will stay watertight and worry-free.

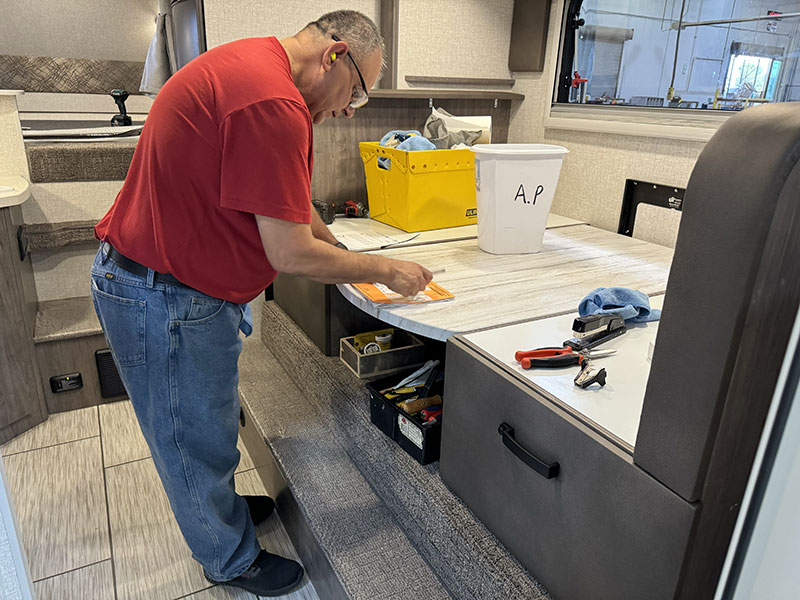

Once the roof team finishes their work, the final finishing crew takes over to complete the camper inside and out. By this stage, the unit has passed through multiple checkpoints, with team leaders signing off on hundreds of quality control items. In final finishing, we watched a Lance team member inspect a camper and initial a quality control deck. This camper is just about ready to roll.

See the yellow bars on the floor? That’s where the end of the Lance truck camper line crosses with the end of the Lance travel trailer line. Now look just past the Lance truck camper. What is that? That, my fine truck camper loving friends, is a Class B motorhome brought to Lance Campers by their new President and CEO, Bill Rex.

Step back and you’ll see a physical representation of the crossroads Lance Campers finds itself in—right now. Truck campers represent Lance’s highly evolved legacy. Travel trailers represent Lance’s marketplace breadth. And the Class B motorhome represents Lance’s new possibilities. A Lance Class B? We wouldn’t have believed it except there it was—right there in the Lance Camper building!

Immediately outside the building is arguably the most important part of the entire Lance Camper manufacturing facility; a secondary quality control area. Before these truck campers reached this point, they had been quality control inspected and signed off many times. But here is where all that adds up to make a Lance a Lance.

This final quality control area was in place for decades. Then, an unfortunate decision by the previous ownership eliminated it. After all, why do you need another round of quality control if the camper has already been inspected at every step? I think everyone reading this knows the answer, but here goes: because that’s how you make a good camper great.

We were also thrilled to learn that the team leader and team who were previously responsible for this final quality control step are back at their station. Bill Rex has promised to bring Lance back to glory. This is one place where he’s putting his money where his mouth is to make that happen.

Turn 180 degrees from the final quality control inspection area, and you’re presented with a sea of Lance truck campers and travel trailers waiting to be delivered to RV dealerships across the United States and Canada.

As a teaser, we were presented with a new and as yet unannounced Lance truck camper model in this area. We can’t reveal exactly what it was just yet, but the floor plan looks like a winner.

Oh, and there was another Lance truck camper floor plan in the Lance R&D area, and another on the production floor. It seems Bill Rex has given the green light for a number of new Lance truck camper models. The R&D team is full steam ahead and truck campers aren’t playing second banana to trailers anymore.

Now that’s the Lance Campers we remember!

Left to right: Matthew Koverman, Executive Director of Operations, Paul Rex, VP, quality control lead, Bill Rex, President & CEO, and Gary Conley, National Sales Manager

In the last hour of our visit, the Lance leadership team joined us at the end of the production line. Naturally, we asked for a group photo and the team pulled in a quality control lead for the shot. That speaks to the priority this team is giving to quality control. As Bill Rex explained it to us, quality is everything.

Walking back to our camper for the night, we passed by a stack of Lance decals featuring the original Lance logo. For the record, I gave the previous marketing team some serious guff about changing Lance’s iconic logo. What were they thinking?

Well, guess what? Lance is bringing back their original logo! This is mostly symbolic, but it’s another positive sign that, under Bill Rex’s leadership, Lance is getting back to what made them a stalwart company and brand.

It may surprise you to hear this, but we’ve heard from many truck camper industry leaders that directly compete with Lance that they’re rooting for Lance to come back strong. Based on what we saw at the factory and our time with both the management and production teams, that’s exactly what’s happening.

For more information about Lance Camper, visit LanceCamper.com. Click here to get a free Lance Camper brochure.