TCM visits Four Wheel Campers and discovers huge leaps in technology and 5S Lean Manufacturing. Here’s how this storied company has continued to push innovation and production without losing its quality, heart and culture. Hint: Precision with passion.

In our eighteen year publishing tenure, few truck camper manufacturers have approached the level of growth of Four Wheel Campers. Since our founding, the trail-blazing aluminum-framed pop-up camper company has moved to bigger and better locations three times while simultaneously expanding their team, embracing 5S lean manufacturing, and advancing their manufacturing technology.

Four years after their latest move in 2021, we finally had the opportunity to visit Four Wheel Campers. Most of our visit was spent walking the manufacturing floor and observing critical advances in equipment and machinery, improvements in productivity and efficiency brought by 5S lean manufacturing, and time-tested and proven techniques that haven’t changed—and shouldn’t change—as they produce results that technology hasn’t surpassed.

Can multiple CNC machines co-exist with manual processes invented when the company was founded in 1972? Yes, they can, and they do. And that wasn’t the most profound observation we took away from our visit.

From the outside, the current FWC factory is a rather generic 140,000 thousand square foot building. If not for the Four Wheel Camper sign and campers in the holding yard, you would have no idea that this was a major camper manufacturer.

The presentation got a bit more familiar standing on a mezzanine overlooking the vast production floor. Looking one way we found rows of high-rise storage racks full of neatly stacked parts and materials, the sewing team, and a glimpse of two parallel production lines running down the center of the factory.

Turning the other way, we traced aluminum ducting to three CNC routers and other wood and composite-working machines. Interwoven into this scene were hundreds of drop-down lines to power a myriad of tools, fans, and stereos that keep the process pumping forward.

Between the visual density, human and machine activity, and the swirl of sounds emanating from the small manufacturing city before us, it was hard not to reflect on just how far Four Wheel Campers has come in the scant eighteen years we’ve known the 53-year-old company.

Descending to street level, the density gave way to focused process and organization. For example, the high-rise storage racks revealed components, parts, and materials precisely prepped and labeled for production.

Starting in early 2018, Four Wheel Campers implemented a full 5S lean manufacturing system (aka the Toyota Method) that included a 10-week extensive staff retraining, a reconfiguring of workflow, standardization of tools and workspaces, and the very beginnings of implementing in-house CNC and automation. From our conversations with the leadership team at the time, the 5S transition was anything but easy. Seven years later, the positive impact on the factory, logistics, and process is unmistakable.

In 2018, Four Wheel Campers also purchased their first Multicam Apex CNC router, allowing them to bring cabinetry production in-house, saving costs and improving quality. Today, FWC has three Multicam Apex CNC routers, often running simultaneously to keep up with the increased production demand.

All three CNC machines are operated by a single dedicated production team member. This showcases a level of efficiency that would have been nearly impossible to imagine when we first toured Four Wheel Campers in 2007.

5S Lean Manufacturing dictates that materials and equipment should be as close as possible to minimize walking, searching, and crossing into other departments. In the above photo, wood and composite panels are stacked within a few feet of the CNC machines. This allows the CNC operator to see the inventory levels, access the materials within his area, and always keep a visual (and an ear) on the CNC machines.

Less than 100 feet from where the Multicam Apex CNC machines were cutting wood and composite panels, a Multicam Celero CNC machine was cutting marine-grade vinyl for a Four Wheel Camper pop-up soft wall. This machine not only dramatically increases the speed of this process, but also the precision.

The materials coming off the Multicam Celero CNC are then brought to the human sewing team to finish for production. Having the soft wall and other required materials cut with consistent precision allows the sewing team to improve their own efficiency, consistency, and precision.

Here you see another sewing team member making a cabover cushion. Beyond the raw materials, appliances, and components (fans, batteries, cooktops, etc.), nearly everything that goes into a Four Wheel Camper is made in-house. This allows FWC to control quality and cost, and minimize reliance on outside vendors.

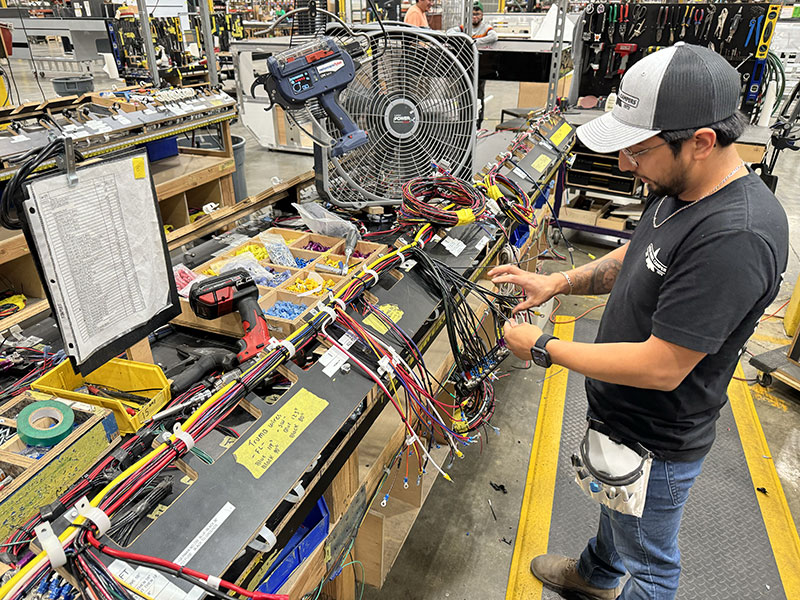

When we first visited Four Wheel Campers in 2007, the campers were relatively simple from an electrical perspective. They had lights, fans, batteries, and basic outlets, but nowhere near the advanced and extensive lithium, solar, inverter, and DC-to-DC systems available from FWC today. Twelve-volt roof air in 2007? Forget-about-it!

Perhaps there’s no better way to see this transformation in camper technology than the complex wiring harness it requires. A few feet from the FWC production line, we watched an electrician building a camper wiring harness with a dedicated jig. Looking closely at his workstation, we noted markers for specific components, models, and an extensive number of options.

Adjacent to the electrician’s work station were these fantastic wheeled wiring organizers. This is another example of the organization brought by 5S Lean Manufacturing.

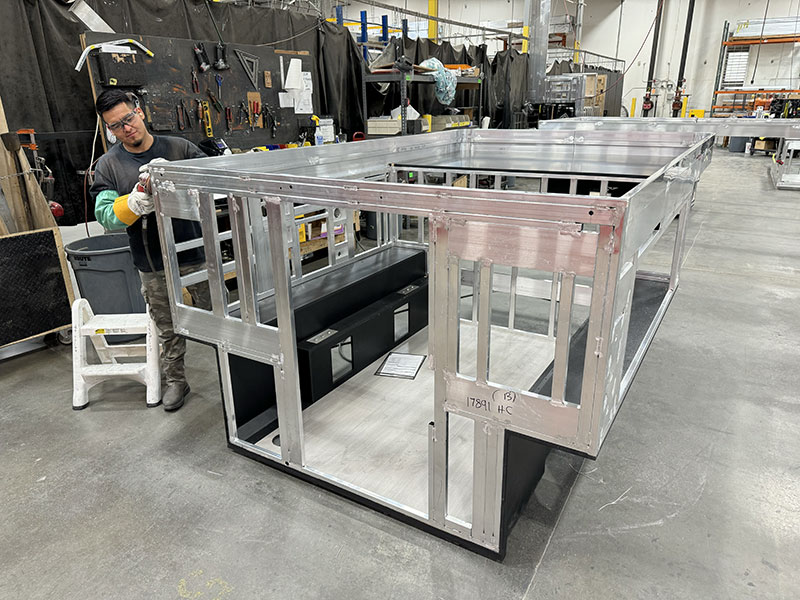

Of course, not everything needed to be changed or advanced when 5S was implemented. For example, the aluminum welding jigs are almost exactly as we found them in 2007.

Tubular aluminum is assembled into these jigs—like a puzzle—and then welded together to create a camper back wall, side wall, or front wall. Same as it ever was.

After starting on a dedicated roof table jig, roof frames are turned vertical allowing the welder to access more areas and add welds for strength. Note how the dedicated roof table jig doubles as a clamp for this process.

Once the back, side, and front walls are welded, another team welds these elements together to create a Four Wheel Camper aluminum frame.

Take a close look at this aluminum frame. It’s the backbone of Four Wheel Campers—an idea that started with Dave Rowe in 1972 and still defines the brand today. If you want to understand why Four Wheel Campers continues to be a dominant force in the off-road truck camper market, much of the answer begins with this remarkably strong, lightweight, all-aluminum construction approach.

Once the lower aluminum frames are completed, they’re placed on wheeled dollies and rolled to the dual production lines.

At the first station, the interior walls and closed-cell foam insulation are installed. Each piece of insulation is hand-cut to fit every space in the aluminum frame, making the structure as airtight as possible. This is an art in itself.

Something about how they fit closed cell foam perfectly into even the smallest frame spaces was deeply satisfying to observe. Much of what makes a Four Wheel Camper may now be done by computer controlled machinery, but human craftsmanship and care are still the key elements on the production lines.

Just to the side of the production lines, an all-female team completes Four Wheel Camper roofs on three large tables. When we asked how the roof team became all female, we were told, “They’re the best at it”. No surprises here.

When the ladies complete a roof, two fellas from the production line carry the roof away and place it into a cradle immediately off the production line.

The finished roofs have their one-piece aluminum skin, lift mechanisms, wiring, lighting, fans, and headliner installed. The roofs are effectively modules designated to specific campers making their way down the production lines.

Once the roofs are mated to their respective campers, the production line team installs the CNC-cut and hand sewn soft walls and aluminum trim.

At this point, we saw four and even five production team members working on a camper at the same time. These guys knew exactly what their individual tasks were and kept the pace moving. It didn’t hurt that a few feet off camera, the music was pumping from a raised speaker. If your Four Wheel Camper happens to give off some seriously good vibes, it may be the upbeat tunes and solid beats it was forged under.

Toward the end of the production line, we saw a cabinet face being completed with hardware, outlets, vents, and controls prior to installation. By finishing these steps on his cart, the team member had immediate access to his tools and a more ergonomic work process.

By working in a more comfortable, better-lit position, he can produce higher-quality results while greatly reducing the risk of scratching or damaging the panel and doors. It’s one more sign of 5S Lean Manufacturing taking root in Four Wheel’s day-to-day operations.

Speaking of carts, the production line team members each have their own carts bristling with tools, all kinds of tapes, adhesives, caulk guns, towels, cleaners—and a huge dose of personality and flair. In fact, the more we looked at these carts, the more we were convinced they were rolling works of highly functional art.

And yes, there were even signs here of the 5S impact. Between the family photos, funny cartoons, and sports team logos, every tool had a specific place outlined where it belonged.

Completed Four Wheel Campers are carefully forklifted from the end of the production line and loaded onto delivery trucks going to fifteen Four Wheel Camper dealers across the United States and Canada.

Following just-in-time manufacturing, these campers were built and completed to be ready for a delivery truck that arrived that day. There are campers that are stored inside the building, but the majority are racked, stacked, and packed on trucks heading out.

How many campers can your truck haul? At Four Wheel Campers, a Ram 3500 can take four or more. Wouldn’t it be funny if three friends got together, bought one truck, and hauled three Four Wheel Campers (one on the truck and two on the trailer) and went camping around the country? Evidently, it’s possible.

Back inside the FWC facility, we toured what has to be the most impressive manufacturer showroom in the business. Here you can literally see every model Four Wheel Campers makes, and their available options. Even better, you can try your hand at lifting and lowering a roof, lie down on a cabover bed to see how you fit, sit in a dinette to check the comfort, and think about where everything you want to bring will be stowed.

It’s one thing to make camper, feature, and option choices online. It’s another to experience them in person.

One small detail in the showroom sent our hearts aflutter. Affixed up high on the wall, we spotted the FOUR WHEEL WAY and POP UP PLACE road signs that once held a prominent place outside their previous 1460 Churchill Downs location. That’s a mere three-tenths of a mile down the same road Four Wheel Campers is located today.

The Real FWC Story

5S Lean Manufacturing and CNC machines have dramatically improved efficiency and quality at FWC, but methodologies and machines can’t build the campers, or take care of its customers. People do.

And that’s the real story here. A company that began as a small family business in Denver, grew into an industry leader in Woodland, California, weathered decades of change, moved multiple times, and still comes out the other side with its focus and culture firmly intact.

Four Wheel Campers hasn’t simply scaled up. Through rapid growth, ownership and leadership changes, recessions, and even a global pandemic, they’ve held onto who they are as a company.

Is the Four Wheel Camper of today the most advanced Four Wheel Camper ever built? You bet. And through it all, FWC has kept its quality, heart, and culture strong—proof that no matter how much the company grows, the values that built it still lead the way.

Click here to request more information about Four Wheel Campers. To visit the Four Wheel Camper website, go to fourwheelcampers.com.