After nearly 70 years of hand-built tradition, Alaskan Campers is reinventing itself with CAD, CNC, and a retooled factory. The craftsmanship is timeless. The technology is cutting-edge. Alaskan isn’t just modernizing. They’re building toward something big.

It had been seven years since our last visit to Alaskan Campers in Winlock, Washington, and a lot had changed. In 2024, the company was acquired by a young, forward-thinking team that ushered in a sweeping wave of modernization, including advanced CAD and CNC technology, upgraded equipment, and refreshed production strategies. We reported these changes when the acquisition was announced, but wanted to see it for ourselves.

At first glance, you’d never guess anything had changed at Alaskan Campers. The main building looks just as it always has, complete with the modest little ‘Alaskan’ sign that’s easy to miss if you don’t know where to look. The leadership team let us in on their plan for a brand-new “Alaskan Campers” sign featuring the updated logo. It’ll blow their low-key cover, but we suspect Alaskan fans won’t mind being able to spot the place a little easier.

Alaskan has recently acquired another even more nondescript building across the street. This 15,000 square foot facility is designated for a top secret Alaskan Camper project we can’t talk about yet. What we can tell you is that this article only scratches the surface of what Alaskan is up to.

Back at the main factory, the team has transformed what was a dark and somewhat dreary entryway area into a bright and cozy customer lounge complete with pillowed sofas, a television, endless WIFI, and free coffee. This was practically an Extreme Makeover experience as we took in all the changes; new paint, new flooring, new furniture, new lighting, and beyond. Move that bus, Ty!

That same spacious room had a swag-laden Ikea shelving unit stocked full of Alaskan-branded mech including blankets, mugs, and gift boxes full of goodies. Want an Alaskan hat or two? They’ll be ready when you pick up your new Alaskan Camper.

If you’re not too busy lounging under your new Alaskan blanket, drinking a complimentary coffee, and watching The Young and the Restless, you can continue straight into the heart of the Alaskan Camper factory. Let’s go.

Taken from the second floor staircase, there are a few things that need pointing out in this photo. First, there are a lot more people working here. According to the leadership team, there are now forty people on staff. That’s easily twenty to thirty percent more than we’ve seen before.

Second, like the customer lounge, this whole space has been reset and reinvented. The initial thing we noticed was the greatly improved LED lighting. The factory had good LED lighting in 2018, but this lighting is brighter, whiter, and raised to the ceiling for even better coverage.

The factory has also been cleared of a few interwoven storage areas that previously clogged the flow of the plant. It’s still a factory full of campers, equipment, materials, and people, but there’s noticeably more open space now.

Finally, take note of all the Rugged Gray Alaskan Campers. This is an option introduced by the new team and it has—to our surprise—become quite popular. Traditional RV thinking states that dark exteriors are to be avoided as they absorb heat. Apparently, new Overland thinking states that Rugged Gray campers look cool. As the saying goes, Rugged Gray is the new black at Alaskan. But don’t worry old-schoolers (yours truly included), you can still get an Alaskan Camper in Classic White.

At the top of the stairs shown above is where the previous photo was taken. Just below the staircase is the customer lounge where you got your free cup of joe and new Alaskan woobie blanket.

The second floor mustard yellow colored structure is the main office area. The offices feature an open floor plan that naturally invites communication. There’s no need for an open door policy if there are no doors. You also lessen the separation between upstairs management and downstairs production with the large non-tinted windows and quick staircase access.

Hold that thought.

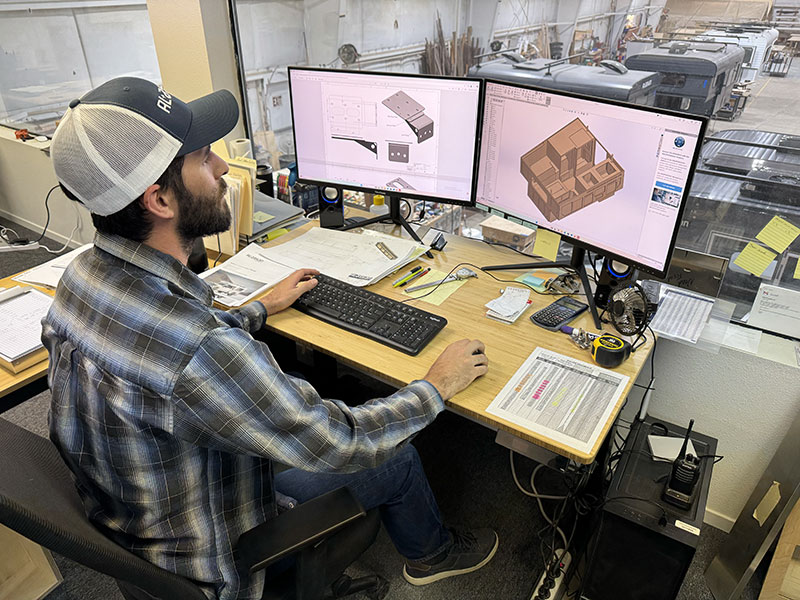

Perched on the second floor with a direct line of sight to production, we found Alaskan’s CAD and Design Engineer, Collin, at his station. Collin has undertaken the considerable task of converting every Alaskan Camper into three-dimensional CAD models.

Through this process, Collin has been able to see opportunities to cut weight, add insulation, expand storage, and improve the structural strength of Alaskan Campers. Essentially, he’s maximizing every aspect of the Alaskan Camper design while maintaining the concept and aesthetic that makes an Alaskan an Alaskan.

At the front of the building, opposite the customer lounge and offices, is the gated shipping and receiving area. A few feet away is a tall bay door where customers pick up their units, and the majority of material and component deliveries enter the building.

So how did they clear out and organize the Alaskan factory? They turned the shipping and receiving area into a warehouse with tall shelving and a computerized inventory management system. We’ve had many truck camper industry leaders tell us their business succeeds or fails by purchasing and inventory management.

There’s a dedicated shipping, receiving, and inventory team that works in the warehouse. This team tracks upcoming Alaskan Camper builds and prepares carts (shown above) stocked with everything the production crew needs from the warehouse. This is one way Alaskan has systematically improved production efficiency.

There are many more production efficiency improvements on display in the wood and cabinetry shop located on the right side of the building. The real game changer is in the rear right corner.

Above: Bruce is the CNC Operator at Alaskan Campers

I’ve said it many times before, and I’ll say it again; CNC and CAD fundamentally change how a camper manufacturer designs, builds, and even thinks about its products. What’s incredible is that Alaskan went decades without CNC or CAD, evolving their iconic product through generations of human-engineered iteration. Now that CNC and CAD are in the Alaskan house, the iteration process is on overdrive.

Above: As the CNC routed cabinets, Angela recorded a video for social media

And here it is, Alaskan’s ShopSabre IS-408—a heavy-duty 4-foot by 8-foot CNC router with a welded steel frame, ball-screw drives, a 10-horsepower spindle, a 12-position tool changer, and a vacuum hold-down table. This machine is touted as a high-volume wood production workhorse. It had better be, considering how much it was running during our two-day visit.

The ShopSabre isn’t the only advanced machine in the wood and cabinetry shop. A few feet from the CNC machine, a TigerStop saw automates the stop and positioning of materials being cut. This dramatically speeds setup time, reduces material waste, and greatly enhances consistency and accuracy. No need to measure twice with a TigerStop.

Above: We would never graffiti our company initials on manufacturer’s equipment—honest!

When I asked the wood shop and cabinet team what this next machine was called, they said, “It’s a time saver”. I said, “Yes, I’m sure it is a time saver, but what is it called? They pointed to the machine where it says, “TIMESAVERS” in all caps. Major face-palm moment.

The Timesaver planer is a wide-belt sander and finishing machine with the specific task of sanding wood cabinetry panels smooth. The team explained that it not only saves time, but also greatly improves the finish consistency from panel to panel.

In addition to speed, efficiency, and accuracy, the combination of CAD and CNC means cutting single parts that once had to be assembled from many pieces. This cabinet face is an excellent example. Where this cabinet face was previously made from multiple hand-cut wood pieces and assembled, it now rolls off the CNC machine, ready for the next step.

All this new technology doesn’t mean Alaskan Campers doesn’t still require craftsmen using time-tested techniques and equipment. The vertical edge belt sander shown above is one of many old-school machines still employed alongside the new tech.

Parts and pieces like cabinet latches and hinges are still installed using hand tools and jigs that would have been at home in the Alaskan factory in 1958.

You might have caught the name ‘COX’ scrolled on the cabinet side in that last image. This is the practice at Alaskan as cabinets are completed for the production line. In the above photo is a cart full of cabinets, similarly labeled for customer builds.

Alright. Now we need to go deep.

Above you see Collin working with Bruce, the CNC operator, about a specific cabinet piece that isn’t fitting right. They’re discussing what changes need to happen in CAD and on the CNC machine to make this piece perfect.

Note this isn’t being handled with an emailed memo or directive from the second floor. Collin is on the production floor working with the CNC operator and cabinet team—listening, observing, hands-on, and returning upstairs to take immediate action.

Here, Collin and Alaskan’s Process Engineer, Chris, are working on another cabinet assembly to find ways to make the process more efficient. It’s no good to design everything in CAD, rout it with CNC, and then ignore the realities on the production floor. Alaskan’s management and production teams are working together to take the products and processes to the next level.

It’s even deeper than that.

We watched Chris taking notes on process, observing how tools are retrieved and returned, and even measuring distances between stations. Where the CAD and CNC guys are focused on the Alaskan Camper product, Chris is hunting process improvements to reduce camper-to-camper variation, cut man hours, improve quality, and generally optimize every facet of the Alaskan Camper factory itself.

Chris’s efforts are creating a lot of forward-leaning changes that must be carefully coordinated and monitored while maintaining production times and camper quality. That’s why the management team is getting out of their second floor seats and onto the factory floor again, and again, and again.

Here’s another excellent example of time-tested techniques merging with modern technology in real time. This CAD-rendered side wall was cut on the CNC machine and then finished using processes detailed in hand-drawn notes captured in an old school 3-ring binder (above left).

We found similar binders in nearly every truck camper factory in 2007, and very few CNC machines. Today, CNC is the rule, and the binders are there for process training, maintaining standards, and keeping records. It may be a digital world, but paper isn’t going anywhere.

The Alaskan production line begins on the rear left side of the building. This first station is where the base is built, walls are attached, outer aluminum skin is applied, and cabinetry is installed. Plumbing, electrical, and major appliances are also installed here.

Across from the first station, the roof team assembles the roofs, installs the wiring, and prepares the top half for one of the coolest manufacturing processes in all of truck camperdom—open-cell polyurethane spray foam insulation.

This process requires a clean and dry surface for proper adhesion. To accomplish this, the roof team used an industrial vacuum to clear the roof of dust and debris. Then they mixed and agitated the two-part polyurethane mix, attached the foam gun, and got to work.

Once mixed in the spray gun and applied, the foam starts to rapidly expand. We’re talking 100 to 120 times its liquid volume within seconds. This is fun to watch, but also requires controlled passes to avoid overfilling the cavities—and possibly triggering a moment straight out of Ghostbusters, Flubber, or The Blob. If this process ever gets out of control, it could answer the question, “Whatever happened to Alaskan Campers?”

After the foam is sprayed into the roof structure, it is shaved using a hand saw. Talk about an old tool. Here I am writing an article about how Alaskan is modernizing and they’re using tools that date back to the Egyptians.

Open-cell polyurethane spray foam insulation creates a lightweight, sound-absorbing, and air-tight seal with a reported R-value of R-3.5 to R-4 per inch. This insulation value is lower than closed-cell foam, but spray foam expands into every cavity, preventing heat loss through air gaps often left by rigid foam.

Once the top and bottom are married, the team installs the roof lift system and signature hard side folding panels. The original Alaskan Camper—invented by Don Hall in 1953 before he started the company—was actually a cabover-less model. It wasn’t until the early 1960s that Alaskan developed essentially the exact same folding panel design shown here. The fact that this folding panel design has endured for over sixty years is simply incredible.

And the folding panels have some interesting advantages on the production floor, like the team can drop down a panel and load the cabover mattress from the side. You can’t do this with any other production truck camper on Earth. Heck, no other camper allows you to completely open the front nose to the outside. We’ve seen Alaskan Campers flexing this capability many times at Overland Expo.

This image shows the entire Alaskan production line on the left side of the building. It’s one of the shortest production lines in the industry. This high productivity-per-foot is possible because of the Alaskan’s technology and teamwork; custom carts from the shipping, receiving, and inventory crew, ready-to-install cabinetry assemblies from CAD, CNC, and the craftsmanship of the wood and cabinetry shop, and the layered efficiencies that come from everything working in concert.

The final piece of new equipment at Alaskan is a BendPak vehicle lift standing 14 feet high in the customer load-out area.

I smiled when I saw this, remembering the team loading Alaskan after Alaskan with nothing more than three three-legged jacks. They were absolute pros, but the BendPack lift brings a level of speed, control, and safety that those jacks could never offer. It’s so easy to use that a magazine publisher can operate it. And I did.

I once asked Bryan Wheat, the previous President of Alaskan Campers, what the oldest piece of equipment at Alaskan was. He brought me to this 1940’s Delta Milwaukee band saw. He suggested it might date back seven decades to the founder’s garage.

If that’s accurate—and we have no reason to doubt it—that means every Alaskan Camper ever made has passed through this band saw. Folks, you’re likely looking at the oldest continuous piece of truck camper factory equipment on the planet. And I, for one, was thrilled to see it still on point.

Let there be no doubt that Alaskan Campers is on the move. According to the leadership team, they’re on target to hit 100 built and delivered Alaskan Campers in 2025. To put that in perspective, that’s nearly double what the company produced prior to 2020.

Let there also be no doubt that Alaskan is working on a next-generation product. That’s all we can say for now, but what’s coming is nothing less than a potential game-changer for the brand. We saw it being built. It’s worth being very excited about.

The leadership team assured us that the existing Alaskan product and design will continue, but the future is on the way. Hang on, Alaskan fans. Things are about to change.

For more information on Alaskan Campers, visit their website at alaskancampers.com. Click here to request an Alaskan brochure.