With unprecedented power requirements, Steve Hericks pushes the RV electrical envelope with a salvaged battery system from a Nissan Leaf electric car. Prepare yourself for inconceivable off-grid electrical possibilities, and amp hours beyond imagination.

For part two of Steve’s remarkable RV power system project, he installs a Nissan Leaf EV battery system into a 2000 Lance 1130 truck camper.

This is a bit like shoehorning a modern Porsche 911 engine into a Volkswagen Beetle (Type 1). Neither was designed for the other, and the results are almost hard to comprehend.

Before proceeding, be sure to read about Steve’s concept and required calculations in part one, “Future Shock: A Bold Vision For RV Power Systems”.

Most electric car batteries are constructed with 48-cells in series (48S) to output 360-volts nominal and over 400-volts fully-charged. This is lethal territory.

This information is provided for informational purposes only by a highly-trained professional with decades of electrical and battery experience. Do not attempt this project under any circumstances.

by Steve Hericks

The Nissan Leaf is the most widely produced electric vehicle (EV) in the world. It also has the benefit that the battery pack is not liquid-cooled (like a Chevy Volt or Tesla).

The Nissan Leaf’s battery weighs 665-pounds and is a closed-steel container. Inside are 48 battery packs, connecting buss bars, and some control equipment. In each pack, measuring a little over 12-inches by 8-inches x 1-3/8-inches and weigh 8.5-pounds, are four cells wired; two in series and two in parallel making each pack 7.5-volts / 64-amp-hours.

The battery packs are very compact and convenient to reuse. A key driver in my choice to use Nissan Leaf batteries was that I could get them into a flat configuration to work in my project camper relatively easily.

I made a quick calculation to see how many of these batteries would be needed for my off-grid power requirements (detailed in part one).

1. Each battery pack has 7.5V x 64ah x 80% = .384kwh capacity

2. 13.077kwh (our energy needed)/.384kwh/battery = 34 battery packs

3. With 48-packs in the Leaf’s battery, we will have some spares.

One key issue regarding using Leaf battery packs is that the packs cannot be disassembled into a usable cells below the pack’s level. For example, a 7.5-volt battery pack operates between 6.0-volts and 8.4-volts.

That raises an important question; Can you make a 12-volt compatible battery with a Nissan Leaf RV battery? Answer; No, you can’t. In fact, you can’t make a 12-volt battery with a Leaf battery or any lithium oxide technology.

The solution I developed is quite technical and required difficult modifications to the batteries that should not be attempted by anyone without the education, skills and extensive professional experience that I have been fortunate to obtain over the past four decades.

The completed battery has 35-packs (140-cells). 30-packs are connected in three series sets of 10 parallel packs making 6S20P. The remaining five packs have been opened and reconfigured to 1S4P, and then connected in parallel making 1S20P.

6S20P + 1S20P = 7S20P. The resulting battery bank has a capacity of 140-cells x 3.75-volts per cell (VPC) x 32Ah = 16.8kwh. The usable portion of this is 80% x 16.8kwh = 13.44kwh.

The simplest solution is 48-volts. Seven packs in series gets you 42.0-58.4V which typically works well with 48-volt inverters.

I settled on a 24-volt system because my power system will eventually be on a custom camper and on a former military truck that can wire directly to the 24-volt vehicle power. That was rigorous and quite possibly mind-bending. I hope you are still with me.

There was not enough space in the Lance 1130 for the number of required Nissan Leaf battery cells. They certainly would not fit into the battery compartment.

I briefly considered putting some of the batteries in the generator compartment. I was already planning to remove the generator, so that space was available.

Due to the generator location on the passenger’s side rear corner, I didn’t want the weight that far rearward – or on one side. I also didn’t want to modify the camper irreversibly since it will eventually be reverted to the factory configuration and sold.

Another possibility was mounting the batteries on the truck. I rejected this approach because the batteries would stay with the truck when the camper was dismounted. I needed a solution to keep the Nissan Leaf’s batteries with the camper.

Thirty-five batteries at 8.5-pounds each weigh 297.5 pounds. That kind of weight has to be kept as low as possible. I finally hit on the idea of making a spacer and attaching it to the bottom of my camper.

I also discovered some unused space to the rear of the wheel wells. This space could accommodate the required control equipment and cable runs.

The spacer is made from a 1.5-inch by 16-gauge steel square tube, arranged into a tray with a half-inch plywood bottom.

#gw_go_portfolio_lithiumbatteryframe .gw-gopf-posts-wrap-inner { margin-left:-20px;margin-top:-20px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-filter-opacity .gw-gopf-col-wrap.gw-gopf-disabled { filter:alpha(opacity=30) !important;-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)" !important;-khtml-opacity:0.3 !important;-moz-opacity:0.3 !important;opacity:0.3 !important; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-col { margin-left:20px;margin-top:20px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-cats { margin-bottom:20px !important; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-filter { margin-left:-6px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-cats > span { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-slider-controls > div { margin-bottom:20px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-slider-controls > div { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-overlay-bg { background-color:#333333; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-overlay-bg { filter:alpha(opacity=30);-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)";-khtml-opacity:0.3;-moz-opacity:0.3;opacity:0.3; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-content { text-align:left; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-more { text-align:left; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-pagination-wrapper { padding-top:20px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-media-wrap img { left:50%;top:50%;-ms-transform: translateX(-50%) translateY(-50%) translateZ(0);transform: translateX(-50%) translateY(-50%) translateZ(0); } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-post-media-wrap { background-position: 50% 50%; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-header { z-index:2; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-btn {color:#1e73be;background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 9px;position:relative;text-align:left;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-btn:hover {color:#1e73be;background:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined:hover {color:#840202;background:transparent;border-color:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-circle {-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;display:inline-block;height:44px;line-height:44px;position: relative;margin-left:3px;margin-right:3px;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;width:44px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-highlight-box{background:#840202;padding:10px;margin:-10px;margin-bottom:10px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span a {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a {background:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a.gw-gopf-btn-outlined { background:transparent;border-color:#840202;color:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span a:hover {background:#000000;color:#1e73be;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-slider-controls > div a {background:#840202;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:table-cell;height:29px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;vertical-align:middle;width:28px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-slider-controls > div a:hover {background:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-slider-controls > div a.disabled {background:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-pagination-load-more {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-pagination-load-more:hover { background:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0.2s;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item:hover {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0s;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover {-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;overflow:hidden;-moz-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-ms-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-o-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-webkit-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;z-index:2;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post:hover, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post {-moz-box-shadow:0 0 0px 0px rgba(0,0,0,0);-o-box-shadow:0 0 0px 0px rgba(0,0,0,0);-webkit-box-shadow:0 0 0px 0px rgba(0,0,0,0);box-shadow:0 0 0px 0px rgba(0,0,0,0);-moz-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-ms-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-o-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-webkit-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;z-index:3;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:before {background:#1e73be;content:'';display:block;height:100%;left:0;filter:alpha(opacity=35); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=35)"; -khtml-opacity:35; -moz-opacity:0.35; opacity:0.35;position:absolute;padding:5px 5px 5px 0;top:-5px;width:100%;z-index:-1;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:before {top:-6px;padding:6px 6px 6px 0;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child:before { left:-5px;padding:5px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:first-child:before { left:-6px;padding:6px 7px 6px 6px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-circle { background:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-circle:hover { background:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn {height:39px;line-height:39px;margin-left:5px;padding:0 15px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined {height:37px;line-height:37px;padding:0 14px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child {margin:0;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content-wrap {position:absolute;width:100%;z-index:1;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content-wrap:before { background-color:#b7b7b7; opacity:0.1;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content { color:#000000;font-family:inherit;font-size:11px;line-height:11px;padding:10px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content a {color:#840202;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content a:hover {color:#000000;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content h2 {color:#000000 !important;font-family:inherit !important;font-size:16px !important;line-height:20px !important;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content h2 a {color:inherit;font-size:inherit !important;line-height:inherit !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content h2 a:hover { color:#000000; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-meta {color:#000000;font-family:inherit;font-size:11px;line-height:11px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-excerpt {font-family:inherit;font-size:11px;line-height:11px !important; margin-top:15px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-excerpt p { font-family:inherit;font-size:11px;line-height:11px !important;margin:0 0 15px !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-excerpt p:last-child { margin:0 !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more { margin-top:15px; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a {color:#000000;font-size:11px;font-weight:bold;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn {color:#1e73be;font-weight:normal;margin-top:-3px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined { color:#000000; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn { margin-left:10px } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn:first-child { margin-left:0; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-content > *:first-child { margin-top:0 !important; } #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux div.gw-gopf-post-highlight-box, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux div.gw-gopf-post-highlight-box:first-child{background:#840202;padding:10px;margin:-10px -10px 10px !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale {background:#840202;-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;color:#1e73be;display:inline-block;font-size:11px;height:44px;line-height:44px;position:absolute;right:10px;text-align:center;top:10px;-moz-transition:opacity 0.1s ease-in-out;-ms-transition:opacity 0.1s ease-in-out;-o-transition:opacity 0.1s ease-in-out;-webkit-transition:opacity 0.1s ease-in-out;transition:opacity 0.1s ease-in-out;width:44px;z-index:5;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post .gw-gopf-woo-sale { filter:alpha(opacity=50); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=50)"; -khtml-opacity:0.5; -moz-opacity:0.5; opacity:0.5;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-woo-price {color:#840202;font-size:22px;font-weight:bold;line-height:22px;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-woo-price del {background:none;color:#b8b8b8;font-size:16px;line-height:20px;margin-right:5px;text-decoration:line-through;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux .gw-gopf-post-woo-price ins { background:none;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap { top:100%;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-up .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-up .gw-gopf-post-overlay-bg {-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap:before { -moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap { bottom:100%;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-down .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframe .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-down .gw-gopf-post-overlay-bg {-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframe .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap:before { -moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;}The spacer is then is divided into compartments to provide weight bearing cross supports for the floor of the camper.

#gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-posts-wrap-inner { margin-left:-20px;margin-top:-20px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-filter-opacity .gw-gopf-col-wrap.gw-gopf-disabled { filter:alpha(opacity=30) !important;-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)" !important;-khtml-opacity:0.3 !important;-moz-opacity:0.3 !important;opacity:0.3 !important; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-col { margin-left:20px;margin-top:20px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-cats { margin-bottom:20px !important; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-filter { margin-left:-6px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-cats > span { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-slider-controls > div { margin-bottom:20px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-slider-controls > div { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-overlay-bg { background-color:#333333; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-overlay-bg { filter:alpha(opacity=30);-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)";-khtml-opacity:0.3;-moz-opacity:0.3;opacity:0.3; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-content { text-align:left; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-more { text-align:left; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-pagination-wrapper { padding-top:20px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-media-wrap img { left:50%;top:50%;-ms-transform: translateX(-50%) translateY(-50%) translateZ(0);transform: translateX(-50%) translateY(-50%) translateZ(0); } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-post-media-wrap { background-position: 50% 50%; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-header { z-index:2; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-btn {color:#1e73be;background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 9px;position:relative;text-align:left;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-btn:hover {color:#1e73be;background:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined:hover {color:#840202;background:transparent;border-color:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-circle {-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;display:inline-block;height:44px;line-height:44px;position: relative;margin-left:3px;margin-right:3px;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;width:44px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-highlight-box{background:#840202;padding:10px;margin:-10px;margin-bottom:10px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span a {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a {background:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a.gw-gopf-btn-outlined { background:transparent;border-color:#840202;color:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span a:hover {background:#000000;color:#1e73be;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-slider-controls > div a {background:#840202;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:table-cell;height:29px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;vertical-align:middle;width:28px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-slider-controls > div a:hover {background:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-slider-controls > div a.disabled {background:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-pagination-load-more {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-pagination-load-more:hover { background:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0.2s;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item:hover {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0s;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover {-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;overflow:hidden;-moz-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-ms-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-o-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-webkit-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;z-index:2;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post:hover, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post {-moz-box-shadow:0 0 0px 0px rgba(0,0,0,0);-o-box-shadow:0 0 0px 0px rgba(0,0,0,0);-webkit-box-shadow:0 0 0px 0px rgba(0,0,0,0);box-shadow:0 0 0px 0px rgba(0,0,0,0);-moz-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-ms-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-o-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-webkit-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;z-index:3;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:before {background:#1e73be;content:'';display:block;height:100%;left:0;filter:alpha(opacity=35); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=35)"; -khtml-opacity:35; -moz-opacity:0.35; opacity:0.35;position:absolute;padding:5px 5px 5px 0;top:-5px;width:100%;z-index:-1;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:before {top:-6px;padding:6px 6px 6px 0;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child:before { left:-5px;padding:5px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:first-child:before { left:-6px;padding:6px 7px 6px 6px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-circle { background:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-circle:hover { background:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn {height:39px;line-height:39px;margin-left:5px;padding:0 15px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined {height:37px;line-height:37px;padding:0 14px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child {margin:0;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content-wrap {position:absolute;width:100%;z-index:1;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content-wrap:before { background-color:#b7b7b7; opacity:0.1;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content { color:#000000;font-family:inherit;font-size:11px;line-height:11px;padding:10px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content a {color:#840202;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content a:hover {color:#000000;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content h2 {color:#000000 !important;font-family:inherit !important;font-size:16px !important;line-height:20px !important;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content h2 a {color:inherit;font-size:inherit !important;line-height:inherit !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content h2 a:hover { color:#000000; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-meta {color:#000000;font-family:inherit;font-size:11px;line-height:11px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-excerpt {font-family:inherit;font-size:11px;line-height:11px !important; margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-excerpt p { font-family:inherit;font-size:11px;line-height:11px !important;margin:0 0 15px !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-excerpt p:last-child { margin:0 !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more { margin-top:15px; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a {color:#000000;font-size:11px;font-weight:bold;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn {color:#1e73be;font-weight:normal;margin-top:-3px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined { color:#000000; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn { margin-left:10px } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn:first-child { margin-left:0; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-content > *:first-child { margin-top:0 !important; } #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux div.gw-gopf-post-highlight-box, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux div.gw-gopf-post-highlight-box:first-child{background:#840202;padding:10px;margin:-10px -10px 10px !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale {background:#840202;-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;color:#1e73be;display:inline-block;font-size:11px;height:44px;line-height:44px;position:absolute;right:10px;text-align:center;top:10px;-moz-transition:opacity 0.1s ease-in-out;-ms-transition:opacity 0.1s ease-in-out;-o-transition:opacity 0.1s ease-in-out;-webkit-transition:opacity 0.1s ease-in-out;transition:opacity 0.1s ease-in-out;width:44px;z-index:5;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post .gw-gopf-woo-sale { filter:alpha(opacity=50); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=50)"; -khtml-opacity:0.5; -moz-opacity:0.5; opacity:0.5;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-woo-price {color:#840202;font-size:22px;font-weight:bold;line-height:22px;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-woo-price del {background:none;color:#b8b8b8;font-size:16px;line-height:20px;margin-right:5px;text-decoration:line-through;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux .gw-gopf-post-woo-price ins { background:none;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap { top:100%;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-up .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-up .gw-gopf-post-overlay-bg {-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap:before { -moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap { bottom:100%;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-down .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-down .gw-gopf-post-overlay-bg {-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetubing .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap:before { -moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;}Above: Cable pass-throughs were made by cutting through the 1.5 square frame and reinforcing with a 1.5l piece of 1h x 2w tube, fully welded and ground on both sides.

Above: Pack layout is 10-2S2P packs in the front compartment, 10-2S2P packs and 5-4P packs in the second compartment and 10-2S2P packs in the rear compartment.

Ten battery packs are connected in parallel to a common buss bar with 8-gauge wire. The buss bar is connected between parallel sets with a pair of 2-gauge wires.

In the Leaf’s car battery, each pack delivered up to 90-amps. In the camper battery set-up, the same batteries deliver a maximum of 23-amps. The inverter can draw up to a continuous 190-amps, with a 5-second max of 267-amps.

#gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-posts-wrap-inner { margin-left:-20px;margin-top:-20px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-filter-opacity .gw-gopf-col-wrap.gw-gopf-disabled { filter:alpha(opacity=30) !important;-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)" !important;-khtml-opacity:0.3 !important;-moz-opacity:0.3 !important;opacity:0.3 !important; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-col { margin-left:20px;margin-top:20px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-cats { margin-bottom:20px !important; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-filter { margin-left:-6px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-cats > span { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-slider-controls > div { margin-bottom:20px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-slider-controls > div { margin-left:6px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-overlay-bg { background-color:#333333; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-overlay-bg { filter:alpha(opacity=30);-ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=30)";-khtml-opacity:0.3;-moz-opacity:0.3;opacity:0.3; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-content { text-align:left; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-more { text-align:left; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-pagination-wrapper { padding-top:20px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-media-wrap img { left:50%;top:50%;-ms-transform: translateX(-50%) translateY(-50%) translateZ(0);transform: translateX(-50%) translateY(-50%) translateZ(0); } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-post-media-wrap { background-position: 50% 50%; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-header { z-index:2; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-btn {color:#1e73be;background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 9px;position:relative;text-align:left;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-btn:hover {color:#1e73be;background:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-btn.gw-gopf-btn-outlined:hover {color:#840202;background:transparent;border-color:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-circle {-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;display:inline-block;height:44px;line-height:44px;position: relative;margin-left:3px;margin-right:3px;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;width:44px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-highlight-box{background:#840202;padding:10px;margin:-10px;margin-bottom:10px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span a {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a {background:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span.gw-gopf-current a.gw-gopf-btn-outlined { background:transparent;border-color:#840202;color:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span a:hover {background:#000000;color:#1e73be;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-cats > span a.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-slider-controls > div a {background:#840202;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:table-cell;height:29px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;vertical-align:middle;width:28px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-slider-controls > div a:hover {background:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-slider-controls > div a.disabled {background:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-pagination-load-more {background:#000000;-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;color:#1e73be;display:inline-block;font-family:inherit;font-size:11px;height:29px;line-height:29px;padding:0 10px;text-decoration:none;-moz-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-ms-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-o-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;-webkit-transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;transition:color 0.08s ease-in-out, background-color 0.08s ease-in-out, border-color 0.08s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined {color:#000000;background:transparent;border:solid 1px #000000;height:27px;line-height:27px;padding:0 8px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-pagination-load-more:hover { background:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-pagination-load-more.gw-gopf-btn-outlined:hover { background:transparent;border-color:#000000;color:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0.2s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0.2s;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux.gw-gopf-isotope-ready .gw-gopf-isotope .gw-gopf-isotope-item:hover {-moz-transition:-moz-transform 0.8s, opacity 0.8s, z-index 0s 0s;-ms-transition:-ms-transform 0.8s, opacity 0.8s, z-index 0s 0s;-o-transition:-o-transform 0.8s, opacity 0.8s, z-index 0s 0s;-webkit-transition:-webkit-transform 0.8s, opacity 0.8s, z-index 0s 0s;transition:transform 0.8s, opacity 0.8s, z-index 0s 0s;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover {-moz-border-radius:0px;-webkit-border-radius:0px;border-radius:0px;overflow:hidden;-moz-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-ms-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-o-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;-webkit-transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;transition:padding 0.2s ease-in-out, margin 0.2s ease-in-out, z-index 0s 0.2s ease-in-out;z-index:2;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post:hover, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post {-moz-box-shadow:0 0 0px 0px rgba(0,0,0,0);-o-box-shadow:0 0 0px 0px rgba(0,0,0,0);-webkit-box-shadow:0 0 0px 0px rgba(0,0,0,0);box-shadow:0 0 0px 0px rgba(0,0,0,0);-moz-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-ms-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-o-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;-webkit-transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;transition:padding 0.3s ease-in-out, margin 0.3s ease-in-out, z-index 0s 0s ease-in-out;z-index:3;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:before {background:#1e73be;content:'';display:block;height:100%;left:0;filter:alpha(opacity=35); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=35)"; -khtml-opacity:35; -moz-opacity:0.35; opacity:0.35;position:absolute;padding:5px 5px 5px 0;top:-5px;width:100%;z-index:-1;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:before {top:-6px;padding:6px 6px 6px 0;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child:before { left:-5px;padding:5px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined:first-child:before { left:-6px;padding:6px 7px 6px 6px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-circle { background:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-circle:hover { background:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn {height:39px;line-height:39px;margin-left:5px;padding:0 15px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn.gw-gopf-btn-outlined {height:37px;line-height:37px;padding:0 14px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux a.gw-gopf-post-overlay-btn:first-child {margin:0;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content-wrap {position:absolute;width:100%;z-index:1;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content-wrap:before { background-color:#b7b7b7; opacity:0.1;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content { color:#000000;font-family:inherit;font-size:11px;line-height:11px;padding:10px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content a {color:#840202;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content a:hover {color:#000000;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content h2 {color:#000000 !important;font-family:inherit !important;font-size:16px !important;line-height:20px !important;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content h2 a {color:inherit;font-size:inherit !important;line-height:inherit !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content h2 a:hover { color:#000000; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-meta {color:#000000;font-family:inherit;font-size:11px;line-height:11px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-excerpt {font-family:inherit;font-size:11px;line-height:11px !important; margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-excerpt p { font-family:inherit;font-size:11px;line-height:11px !important;margin:0 0 15px !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-excerpt p:last-child { margin:0 !important;padding:0 !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more { margin-top:15px; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a {color:#000000;font-size:11px;font-weight:bold;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn {color:#1e73be;font-weight:normal;margin-top:-3px;text-transform:uppercase;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined { color:#000000; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn.gw-gopf-btn-outlined:hover { color:#840202; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn { margin-left:10px } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-more a.gw-gopf-btn:first-child { margin-left:0; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-content > *:first-child { margin-top:0 !important; } #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux div.gw-gopf-post-highlight-box, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux div.gw-gopf-post-highlight-box:first-child{background:#840202;padding:10px;margin:-10px -10px 10px !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-highlight-box * { color:#1e73be !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-highlight-box a:hover { color:#000000 !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale {background:#840202;-moz-border-radius:22px;-webkit-border-radius:22px;border-radius:22px;color:#1e73be;display:inline-block;font-size:11px;height:44px;line-height:44px;position:absolute;right:10px;text-align:center;top:10px;-moz-transition:opacity 0.1s ease-in-out;-ms-transition:opacity 0.1s ease-in-out;-o-transition:opacity 0.1s ease-in-out;-webkit-transition:opacity 0.1s ease-in-out;transition:opacity 0.1s ease-in-out;width:44px;z-index:5;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post:hover .gw-gopf-woo-sale, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux .gw-gopf-current.gw-gopf-post .gw-gopf-woo-sale { filter:alpha(opacity=50); -ms-filter:"progid:DXImageTransform.Microsoft.Alpha(Opacity=50)"; -khtml-opacity:0.5; -moz-opacity:0.5; opacity:0.5;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-woo-price {color:#840202;font-size:22px;font-weight:bold;line-height:22px;margin-top:15px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-woo-price del {background:none;color:#b8b8b8;font-size:16px;line-height:20px;margin-right:5px;text-decoration:line-through;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux .gw-gopf-post-woo-price ins { background:none;text-decoration:none !important;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap { top:100%;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-up .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-up .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux-push-up .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-up .gw-gopf-post-overlay-bg {-moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-up .gw-gopf-post-content-wrap:before { -moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap { bottom:100%;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-down .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap {border-radius:0px;-webkit-transition:-webkit-border-radius 0.1s ease-in-out;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-down .gw-gopf-post:hover .gw-gopf-post-media-wrap, #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-touch.gw-gopf-style-delux-push-down .gw-gopf-current.gw-gopf-post .gw-gopf-post-media-wrap {-moz-border-radius:0;-webkit-border-radius:0;border-radius:0;-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-down .gw-gopf-post-overlay-bg {-moz-border-radius-bottomleft:0px;-moz-border-radius-bottomright:0px;-webkit-border-bottom-left-radius:0px;-webkit-border-bottom-right-radius:0px;border-bottom-left-radius:0px;border-bottom-right-radius:0px;} #gw_go_portfolio_lithiumbatteryframetoggleclamps .gw-gopf-style-delux-push-down .gw-gopf-post-content-wrap:before { -moz-border-radius-topleft:0px;-moz-border-radius-topright:0px;-webkit-border-top-left-radius:0px;-webkit-border-top-right-radius:0px;border-top-left-radius:0px;border-top-right-radius:0px;}The finished spacer attaches to the bottom of the camper with six toggle clamps. Power connections have high current connectors so the battery can be completely removed in a couple minutes by sitting the camper on 4x4s, releasing the clamps, and lifting the camper off the spacer using the jacks. I have not needed to remove the battery system since I installed it.

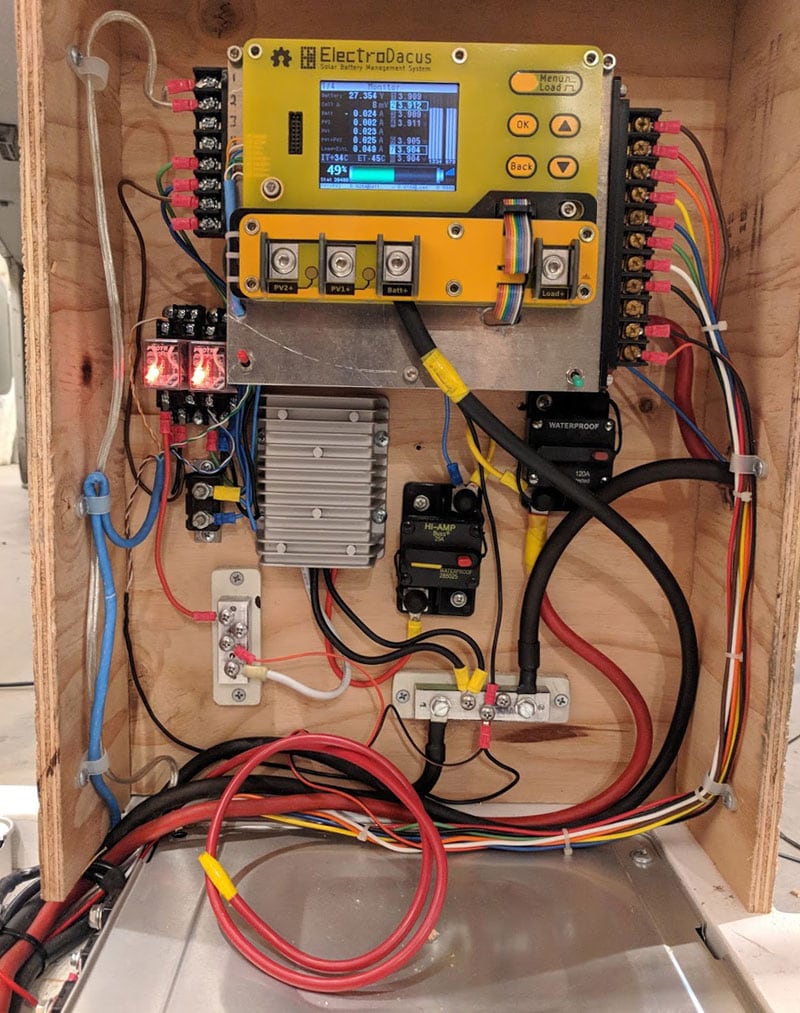

Above: On the passenger’s side is a blue CAT5 cable connecting the BMS to the inverter to communicate ‘okay to invert’ and ‘okay to charge’.