Starting with Charlie Coushaine’s Top Mod Contest Winning laser loader, here are four proven truck camper laser loading solutions designed to make loading a light task. Get ready for truck camping, with laser beams.

The very first Laser Loading system in Truck Camper Magazine was also one of our very first mod winners, Charlie Coushaine. Since then, other readers have also shared their different laser systems to load campers. First, is Charlie’s winning mod and video. Then check out the other laser ideas that have been shared over the years.

1. Laser Loader For Slide-In Campers

Submitted by: Charlie and Jeannie Coushaine, 2001 Ford F350, 2012 Chalet DS116RB

Ever since I got a truck camper, and Bill Penney at Truck Camper Warehouse showed me how to hook it up to my truck, I thought that there must be a better way to align the truck and camper to make loading less stressful.

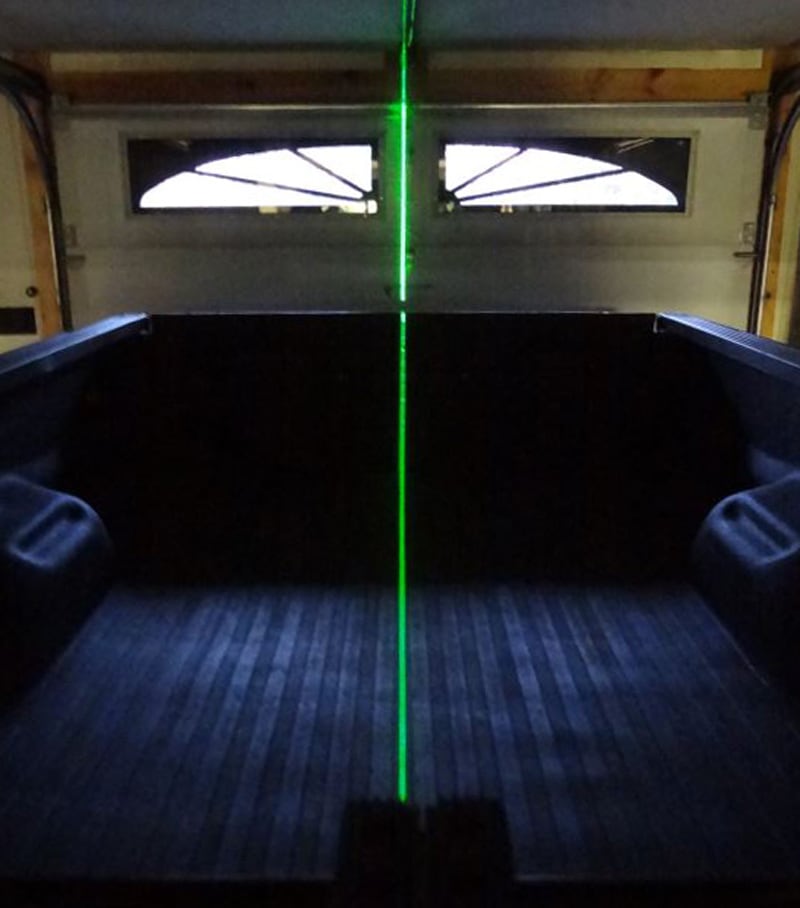

After much thought and design, I was able to design and install a low-powered, safe, green laser line that projects out the sliding rear window of my truck to form a plane. This in turn is matched with three centered registration points I placed on the front of my camper to form a mating plane.

I then just back up, aligning the projected laser plane with the plane on my camper, and the two align perfectly – every time! No more guessing about misalignment and a stress-free hook-up.

To begin the build, I purchased a four to five mW green laser that projects a line, not a point. With this, I added a heat sink, 3V battery pack with a switch, and a mounting plate.

I assembled these all together and mounted them to the inside of my truck such that opening the back sliding window allows for projecting a perfectly vertical and centered green laser line down the back of my truck bed.

I then purchased some reflective tape (so the laser can be seen during daylight), cut it into three pieces, drew a vertical line down the middle of each, and stuck the three pieces on the front of my camper to form a central plane.

I have used this alignment system multiple times now and each time the alignment has been perfect!

2. Magnetic Laser Loading System

Submitted by: Philip Bogardus, 2014 Ford F350, 2018 Northern Lite 8-11 EXSE

We recently bought our first camper. My Queen (aka my wife) and I found the loading of the camper was both time-consuming and stressful.

I studied many YouTube videos on how to load your camper and tried several of them. I found some of them helpful, but we still found the camper loading experience was the same no matter what method we used.

I then found Charlie Coushaine’s Top Mod winning Laser Loading System (see above) on the Truck Camper Magazine. Being an engineer, this looked like a very elegant solution. I showed the video to my Queen and she said I needed to build a laser for loading our camper.

I own a 2014 Ford F-350 Lariat. It has a rear seat and center headrest, so permanently mounting the laser as Charlie did would not work for my truck. I needed a laser system that could be installed when loading the camper and then removed after it was loaded.

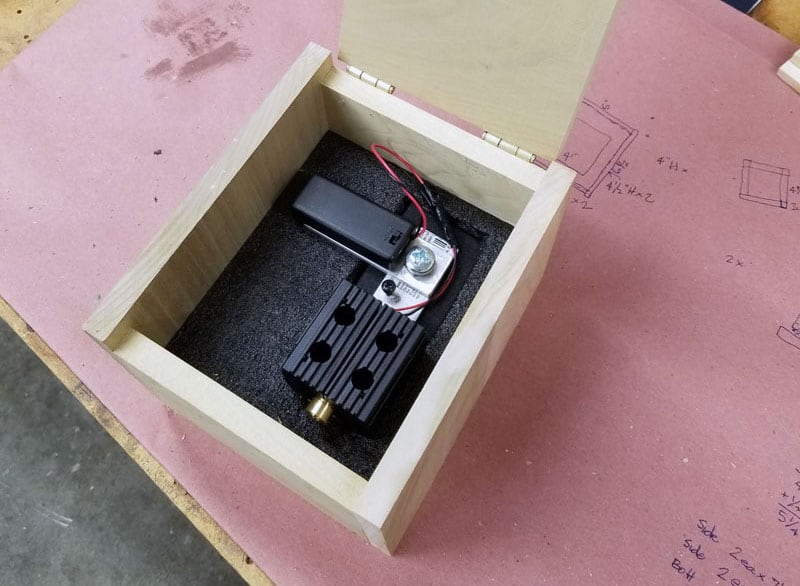

My solution was to mount the laser on a magnetic switch that could be installed and removed. I purchased the same laser setup that Charlie had used (Z-Bolt DPSS-5L, 12mm Green Line Laser, DC Power Supply, and HS-1a Heat Sink).

I had a Harbor Freight Multi-Position Magnetic Base (Item #63663) which has a switch to turn the magnet on and off.

My pickup bed has a sprayed-in liner. The magnet did not have enough power to hold through the liner.

To solve this problem I took some flat bar, painted it black, and screwed it to the pickup’s bed rail near the back window for the magnet to mount on. If your truck bed is aluminum then you would also need to do this.

For the laser, I used two pieces of aluminum flat bar to mount the laser heat sink and battery supply to. The aluminum flat bars were then mounted with a single bolt into the screw mount of the switchable magnet.

I measured between the bed rails to establish the center of the truck bed and marked the mounting plate. I then mounted the laser centered on this line. Using double-sided tape, a piece of aluminum flat bar with two holes predrilled was mounted along the vertical edge of the switchable magnet. This vertical alignment bar would serve as the laser’s registration line when being installed.

Next, I aligned the laser to center on the entrance end of the truck bed. I followed the instructions Charlie provided in his video to align the laser. I had to make some adjustments of the laser in the heat sink mount and on the magnet mount to get everything lined up. After some minor tweaking of each, the laser line was centered on the truck’s bed – just like Charlie’s.

Now that the laser was set and aligned, I drilled through the predrilled holes in the vertical alignment bar into the metal mounting plate. Screws were then installed to attach the vertical alignment bar to the mounting plate.

As you can see from the photo, I originally intended to install two vertical alignment bars which the laser would be mounted in between. After I got the first bar installed I realized that all I had to do was set the vertical edge of the switchable magnet flush against the vertical alignment bar and the second vertical bar was not needed.

Finally, I installed 3M Silver White Reflective Vinyl Tape (from Amazon) on my truck camper as Charlie described in his video and we were ready to load the camper with the laser alignment system.

One thing I did discover is that I must adjust my camper side-to-side to match the reflective tape marks with the laser line. My driveway is sloped from side-to-side. As a result, the laser line is not truly vertical. By adjusting the camper side-to-side to match the laser I get the proper alignment for loading in one try.

I built a small wood box to store the laser mount in when traveling. I used some FastCap 30mm Foam (Woodcraft Item #850575) inside the storage box to protect the laser unit.

To load the camper, I set the switchable magnet’s vertical edge against the vertical alignment bar and attach the laser to the mounting plate. I then turn on the laser and then check that it is centered between the bed rails at the tailgate. I then load the camper and stop when the laser is very close to hitting the camper. I switch off the magnet, remove the laser and finish backing up the truck to the camper.

My magnetic mounting modifications for Charlie’s laser system have worked out great. It is the perfect solution when you can’t mount the laser in a permanent location. My Queen and I find loading of the truck camper is now much easier, faster and a lot less stressful. We can load it quickly and typically hit the mark the first time.

It took me six hours to complete this modification and cost me $120. In my opinion, the skill level of this modification is medium.

3. Air Grip Laser Level To Load Camper

Submitted by: Jim Pippin, 2007 Dodge Ram 2500, 2008 Lance 825

My modification is using a laser level to aid in loading my truck camper. Using Velcro we attached a Ryobi battery-powered Air Grip Laser Level (around $19) to the center of the lip on the rear wall of the bed of our pickup truck. We had measured and found the center of the front wall of our truck camper and marked it.

With the beam on (it creates a long red, easily seen line) we are able to back up precisely positioning our truck under our camper. We remove and store the laser just before we back in those last few inches. This has made loading our truck camper much easier.

4. Laser Loading a Lance 1172

Submitted by: Donald Fox, 2015 Ford F450, 2016 Lance 1172

I am new to truck camper ownership and was having to spend over one hour getting the truck and camper to load with appropriate space on each side. This is the first of two or three steps I will take to make loading extremely easy, even for a newbie.

I wanted assistance in loading my truck camper, a 2016 Lance 1172 onto a Ford F450. I have 2½-inches on each side at the cab area and only 1-inch each side at the tailgate once the camper is loaded. That’s not much room for error.

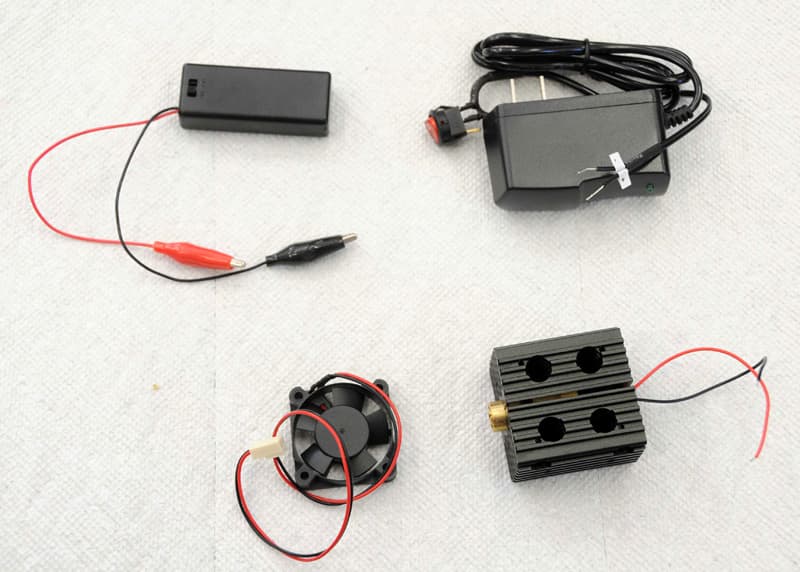

I purchased a 12mm Laser Line Green Generator (5mW) because they show up better than red. As part of the laser light, I also purchased a 12mm heat sink module (helps cool the laser), a cooling fan, and a 3V power supply AC plug and toggle switch actuator. This allowed me to plug into the truck’s power source and reach the open rear window of the truck.

|  |

Above: Laser with support bracket and electric and close up of laser attached to the truck’s sliding rear window

I tried several ways to temporary attach the laser so that it was level. Finally, I found that I could fold down the rear seat backs. Behind that location was a place to screw a metal support bracket permanently. When needed, I could attach the laser line to the support bracket. I made a 45-degree metal frame for the laser light to be attached to the support.

Above: Level line sample with cardboard

After installation, which now takes about one minute, I check that the laser is level north, south, east, and west with the tailgate and make minor adjustments.

Above: The important process for loading using a laser line is to make certain that the truck bed and truck camper are level with each other. That is why Donald has to have one side of my truck camper up higher than the other; also note the reflective tape.

I also place reflective tape on the camper in three to four places. One is at the camper’s front, one at the center near the window, and one at the bottom.

I back up the truck under the camper’s front and take measurements left and right. Then, I raise or lower the camper to be the same height on both sides of the truck. In my case I have to raise the camper 1½-inches on the passenger’s side so all is level. If you don’t do this, your line level light will not really allow you to back into the camper as it will give you a false indication that you are level. This took me about two hours to figure out, but now it is done prior to attempting to load.

The light then sends its beam toward the truck camper and at the three reflectors. If all three are in the path of the laser line I know that I am exactly square with the truck for loading. I then backup and keep the three reflectors in the laser light. If any one of them is not in the light, I am no longer level.

Above: Plug-in laser with small cooling fan

Because I was experimenting; I came up with four ways to complete the making of a laser light system.

1. The one described above, which cost about $75.

2. Doing everything described above, but not including the cooling fan. That cost about $65.

3. Use of a AAA battery rather than plugging into 120-volt system. That cost about $55.

4. I purchased a really cheap laser dot light designed to be attached to a circular saw. I gutted and threw away the original dot light as it was not able to cast a light over one foot. Then I installed the 5mW green laser generator into the skeleton. This system is the easiest, as it has a small magnet at its base and can easily attach without damaging truck paint. It can be moved around to become completely level. It does not have any means to keep the light cool which will be okay once someone learns how to use it. That cost about $55.

Above: Another way for the laser to be attached; a wooden support that will hang on the truck’s rear seat

Above: The laser attached to wooden support hanging on the truck’s rear seat

I went from one hour to only fifteen minutes loading time. I can also load without a spotter in that fifteen minutes. That said, I always recommend a spotter no matter how good you are at loading your truck camper.

It took me three days to complete this modification, but only two hours once I figured out how to make an effective support system. It cost $75. I have made six of them and will sell them at a later truck camper meet. In my opinion, the skill level of this mod is hard.

Disclaimer: The modifications above are submitted by Truck Camper Magazine readers. It is your responsibility to make sure that any do-it-yourself modification project you undertake is safe, effective, and legal for your situation.