Stablecamper launches their first product; an innovative aircraft-grade aluminum camper stabilizer. A second truck camper product is already in the works.

It’s amazing how few products and accessories speak directly to the truck camper marketplace. Walking through a RV store, there are entire departments, aisles, and end caps devoted to the needs of fifth-wheel, travel trailer, and motorhome owners – but products specifically for truck campers? Not so much.

By conservative estimates, there are over 100,000 active truck camper owners in the United States and Canada. That’s a considerable market size. So why aren’t there more truck camper products and accessories?

Meet husband and wife team Jared and Candice Sund. Jared is a life-long machinist with a broad background in mechanical engineering, mechanical design, computer science, and software development. Candice is a civil engineer with extensive experience as a project manager for major commercial projects.

Although Jared and Candice were both highly successful in their demanding careers, deep down they always wanted to do their own thing. Add the fact that the Sunds also happen to be extremely passionate truck camper owners and you begin to see how this story is about to get very interesting.

What follows is the remarkable account of how Jared and Candice came to start Stablecamper; an all-new truck camper products and accessories company. Stablecamper’s first product is a unique and patented approach to stabilizing an unloaded truck camper. Their second product is already in development and several more are in the works.

From our initial conversations, there can be no doubt that Jared and Candice are on a mission to bring more innovative truck camper products and accessories to the truck camper marketplace. To find out more about their new company, we talked to Jared and Candice Sund.

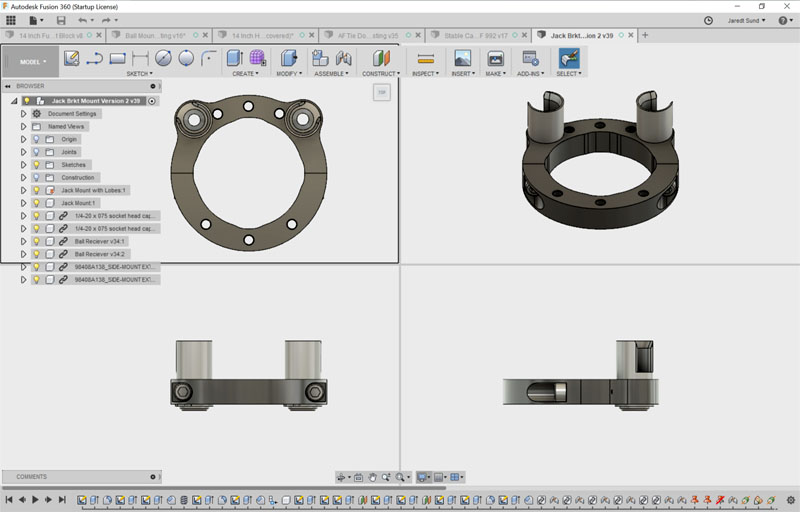

Above and below: The Stablecamper camper stabilizer system

TCM: Before we talk about Stablecamper and your first product, tell us about your professional backgrounds.

Candice: I’m a civil engineer. I worked in construction as a project engineer for general contractors. I was also the project engineer for a commercial building in downtown Portland.

In both capacities I made sure everything was built on time, on budget, and to specification. If there was an issue, I would work with our architect and fellow engineers to find a solution.

I have used my engineering experience and skills extensively for Stablecamper. I also work on product design, sourcing, marketing, construction, and website design. There are many hats that are worn in a small business.

Above: Candice And Jared Sund, Owners of Stablecamper, with their daughter, Taylor

Jared: My father, who is also part of Stablecamper, always had a machine shop. I grew up learning machining and later went to school for computer science.

I have extensive experience in mechanical design product development in a variety of industries. In addition to my product development experience, I also have an extensive background in software development.

I was a Director of Product Development at a large software company and ran the Product Data Management group. As a Director, I was exposed to hundreds of products in development by small startups to big multinational corporations. An important part of my job was to learn about their production challenges and present them with solutions.

TCM: You are describing your careers in past tense. Are you now 100-percent focused on Stablecamper?

Jared: Yes, we left our careers to start Stablecamper. We’re in our mid-40s and empty nesters. We always wanted to do something on our own. It was time.

Above: The Sund’s Ram 3500 and Arctic Fox 992 truck camper rig. Note the Stablecamper system tucked under the camper wing

TCM: It just happens that you’re both also passionate truck campers. How did you get into truck camping?

Jared: We were at a neighbor’s house twenty years ago and he had an old Six-Pac truck camper in his backyard. He said, “A buddy left it here and I wouldn’t mind seeing it go”. We wound up getting the camper for three cases of Coors Light. We cleaned it up, rebuilt it, and enjoyed that camper for many years.

As we raised our daughter, Taylor, we went truck camping to national parks throughout the United States and Canada. It was a great way to take a two week family vacation without spending a lot of money.

When Taylor was in high school, she wanted stay at resorts and travel abroad. We did that for a few years, but Candice and I really missed camping. The day before Taylor went to college, we picked up a new Arctic Fox 992. This is our fourth truck camper.

In the last three years we have put thousands of miles on our Arctic Fox rig. We have spent at least 200 nights in our camper traveling across the United States and as far as Nova Scotia. We love truck camping.

TCM: When did the idea for the Stablecamper product first happen?

Jared: We have always built stuff. When we got the 992, we put modular shelving in the wardrobe next to the kitchen. Then, I built a better sewage hose holder and installed a backup camera. We are always building something we need.

One day I was in the dinette while Candice was making breakfast. As she walked around the unloaded camper, I could feel the camper moving and hear the jack points creaking. I thought there must be a product that would solve that issue.

Above and Below: Jared’s computer models of an installed Stablecamper system

I did some research and there wasn’t a product that addressed the whole problem. So I drew up a design in CAD and strapped 2x4s to the camper to test the concept. With the 2x4s installed, the camper was rock solid. From that initial design and test, we built the first version of Stablecamper for ourselves.

Above: Every element of the Stablecamper system was modeled in CAD

A few weeks later, we were out crabbing on the coast and another Arctic Fox camper happened to be right next to us. He also had his camper off the truck, but his was resting on saw horses.

He was so impressed with our stability solution that he said we should make it into a product. That’s when we realized there might be a market for what we built. That was the genesis of Stablecamper.

Above: The Stablecamper system in the stowed under the camper wing

TCM: How did you go about building the final product?

Jared: From that initial CAD drawing and prototype, we refined the design for ease of use and manufacturability. We wanted it to be a nice looking product that was easily portable. Plus, it had to be stored on the exterior of the camper, not inside.

The CAD drawing evolved for about three months. Then we went to the shop to start building the second prototype. Three months later, I had a set powder coated for us.

Once we were happy with the design and function, we got it into the hands of truck camping friends. They had some suggestions, but the overall feedback was extremely positive. Stablecamper completely stabilized the test campers.

Candice: That’s when we changed our focus to making the product more cost effective for manufacturing. I was able to find sources for the materials that were significantly lower. The quality of the materials is the same or better, but the costs are much lower.

Above: The Stablecamper system deployed in the field

TCM: Does the final version of Stablecamper address the front-to-back and side-to-side motion as well as the prototypes?

Jared: Yes. We are very happy with the way Stablecamper turned out, and we believe it stabilizes the camper in all directions.

TCM: Can you really notice a difference between a camper without Stablecamper installed and then with the product installed?

Jared: You notice it immediately. It’s a night and day difference.

TCM: When you did a patent search, you discovered that someone did indeed have a patent that covered your product. How did you proceed after that discovery?

Jared: This is a good story. I did an initial patent search early last summer and didn’t find one related to our product. Then Candice did a double-check in November and found that there was a patent on essentially the same product.

Candice: That’s when I called Jared and let him know what I found and he said, “I think we have a problem.”

Jared: By that time we were really into this project, so I tried to reach out to the patent holder. Months went by and we couldn’t get a hold of him. All the phone numbers and email addresses we found were disconnected. Then Candice found an address somewhere, so I wrote him a letter and overnighted it.

Two weeks later I get a phone call; “Hey, I’m Walt!” I was stunned. It turns out that he also worked in product development, had a similar idea, but it didn’t go anywhere. He developed a couple prototypes, but that’s as far as it got.

We get along really well. In fact, Walt is now part of the Stablecamper team. He has a ton of knowledge about purchasing and manufacturing and is excited to see us sharing in the same product idea. It’s been perfect. Even better, Walt’s also a truck camper guy.

The Stablecamper team: Jim, Walt, Candice, and Jared

TCM: That’s an incredible story. What luck! Why do you think Stablecamper is a better camper stabilizer than what’s currently on the market?

Jared: Nothing else stabilizes the front jacks to address both side-to-side and front-to-back stability. If you look at larger truck campers, the rear jacks are supported at the connection points, but also at the bumper.

The front jacks have four feet of cantilever creating a lot of torque at the front corners. Basic engineering says to box in that area for stability. That’s why the Stablecamper system makes a world of difference.

TCM: Have you been able to test Stablecamper on a variety of truck campers?

Jared: We have tested Stablecamper on a number of truck campers. We list the camper makes and models that Stablecamper works with on our website.

As of now, Stablecamper is compatible with late model Adventurer, Eagle Cap, Lance, Arctic Fox, and Wolf Creek truck campers. We’ll be adding more manufacturers as we confirm dimensions and compatibility.

We have another good story about how we have been testing Stablecamper on different truck campers. While we were steelhead fishing last January, I posted a picture of our rig and drift boat on the Arctic Fox Facebook page.

In the comments, people were asking about the poles on our camper. From that people asked to help beta test the system on their campers. That’s how we expanded our compatibility information.

TCM: It always amazes us what people catch in posted photographs. Are there different Stablecampers for different campers and jack systems?

Jared: There’s a long bed version and a short bed version. For very long campers like the Eagle Cap 1200, we have a special extended version as well.

We have mounting hardware for square Happijac jacks as well as round Atwood and Rieco-Titan jack systems.

TCM: Is Stablecamper compatible with pop-up truck campers?

Jared: We have focused on 10-foot plus hard side campers, but the idea will work on any truck camper; pop-up or hard side.

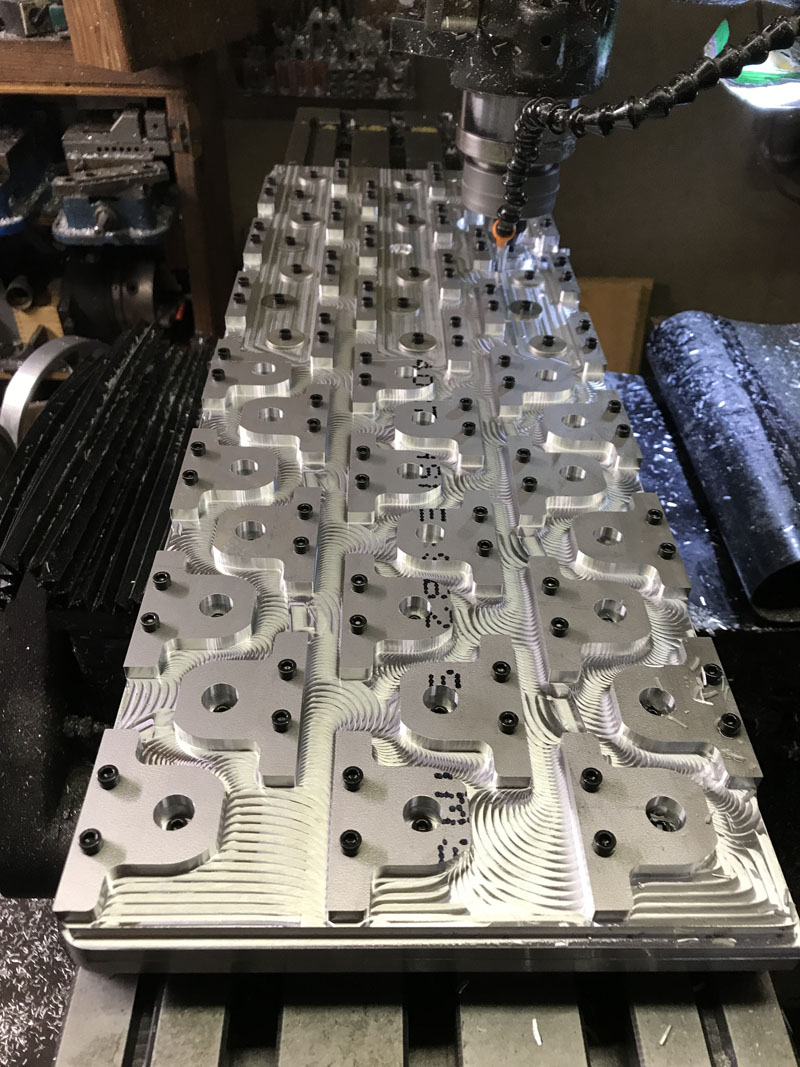

TCM: Is Stablecamper manufactured in-house and 100-percent Made in the USA?

Jared: We haven’t validated that all of the hardware, (bolts, screws, etc.) are made in the United States however, the entire product is made in-house at our facility just outside of Portland, Oregon. We are not sourcing products overseas. Everything is bought and made locally.

Above: Stablecamper’s Haas VMC vertical mill

TCM: How are Stablecamper systems manufactured?

Jared: All of the materials come in raw and are cut on a CNC lathe or milling machine. The round parts are turned on a lathe to eliminate variation.

Some parts are then sent out to a finisher to be tumbled and powder coated. Final assembly is done in-house. Then, we package the product and send it out to the consumer.

TCM: You have some impressive equipment on hand including a Haas VMC vertical mill and a Hardinge CNC lathe. CNC machines seem like a considerable investment for a small machine shop.

Jared: Tools are the best investment for a company. We also use our CNC equipment to help other local manufacturers. We are working to fill our CNC capacity with Stablecamper and other businesses.

The prices other companies are charging for materials and CNC work is outrageous. We are helping to solve that challenge for local manufacturers. The CNC equipment brings a lot of value to Stablecamper and other small businesses.

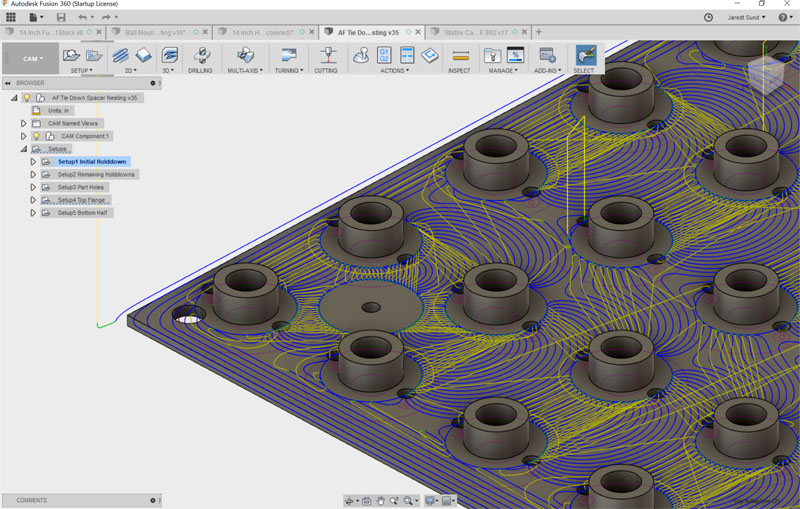

Above: Designing in CAD allows for the most efficient and precise CNC material use

TCM: Why are you building the Stablecamper with aluminum?

Jared: We briefly considered steel tubing to save cost, but it’s much heavier and doesn’t have the feel of high-quality aluminum. Aluminum isn’t cheap, but it’s lightweight, looks great, and you can feel the quality.

Above: CNC routed aluminum parts at Stablecamper

Modern truck campers often reach $40,000 and even $70,000 new. We wanted Stablecamper to match that level of quality. Nice campers need nice products. We want customers to be excited to see and use the product. Stablecamper is also built to last a long time. We built a product we would buy.

TCM: How many people are currently on the Stablecamper team?

Jared: There are four of us. Candice, myself, Walt, and my dad. Dad is retired and loves working in the machine shop. As he often says, “I had a good thing going until you retired from your day job.” Now he’s working with us on Stablecamper.

TCM: Are you looking to grow Stablecamper into a larger company?

Jared: I’ve worked with and managed large teams and it’s nice to have a small company. Our shop could be twice the size it is now, with double the team members. That’s where we’re headed.

We have built strong relationships with our vendors. Our aluminum supplier is now part of our team. You have to have the support of your supply chain to be successful.

TCM: Is the Stablecamper product something that a consumer can install themselves?

Jared: It’s much easier to install than building IKEA furniture. Stablecamper comes with complete installation instructions. It might take an hour to install.

Above: The Stablecamper logo incorporated into the Stablecamper system

TCM: Does any element of the Stablecamper require screwing into the camper itself?

Jared: The side bars do not require any screws into the camper. You install a clamp around the front jacks as the first attachment point and use the rear tie-down bracket as the second attachment point. That’s it.

The front bars (shown above) do require screwing into the camper. The front bars have a bracket that goes on the front of the camper. There are screws supplied to mount these bars.

TCM: Some folks will be hesitant to screw into their camper. Is there another option?

Jared: I’ve thought about no-drill solutions, but I haven’t found one strong enough for the front bars. Again, you can just go with the side bars. They make a huge difference on their own.

We have installed the front bars on our Arctic Fox. We used sealant on the screws themselves and then around the mounting plate. It’s water tight.

TCM: What about customers who don’t want to install the Stablecamper system themselves?

Jared: We would be happy to install Stablecamper systems at our shop in Oregon. If you want us to install the system, please contact us in advance to make an appointment.

Above: A complete Stablecamper set; front bars, side bars, and hardware

TCM: What does the Stablecamper system weigh?

Candice: It’s 22.5-pounds with all the parts. For a long bed camper, the front set is 8.3-pounds and the side set is 16.1-pounds.

Above: A Stablecamper front bar set

TCM: What does a Stablecamper system cost?

Candice: It’s $400 plus shipping for the complete system; side bar, front bar, and required hardware.

Jared: We also sell the side bars and front bars separately. The side bars provide 70-percent of the stability of the complete Stablecamper system. For six months we just used the long side bars and that made a big difference. Customers who install the side bars and brackets could always upgrade later with the front bars, if needed.

TCM: From your description, the side bars are all some folks might require. How does someone go about purchasing Stablecamper products?

Candice: You can order a Stablecamper system, or Stablecamper components on our website.

TCM: Are you looking to stay factory direct only, or are you interested in selling through truck camper dealers?

Jared: Our goal is to establish a dealer network. We are interested in talking to truck camper dealers. Stablecamper could be a dealer installed standard or as an option.

You can add a Stablecamper system any time after purchase, but it makes sense to have it installed when you pickup your camper.

TCM: What is the warranty for Stablecamper?

Jared: We have a lifetime warranty on the Stablecamper system. If you have an issue, call us, tell us your problem, and we’ll work with you to fix or replace it.

TCM: What niche do you see Stablecamper – the company – filling in the truck camper marketplace?

Jared: We want to make products and accessories exclusively for truck campers. There are not many truck camper accessory companies. That’s our focus. Our long term plan is to build the Stablecamper system and other convenience products for truck campers.

Candice: As truck camper enthusiasts, we know what’s required from truck camper products and accessories.

TCM: Obviously you can only have so much success as a one product company. Are there plans to manufacture and sell additional truck camper products?

Jared: As truck campers, we are coming up with new product ideas all the time. And we meet truck camper owners who also have lots of ideas. We are already working on our next product. There is more to come.

TCM: That’s quite a tease. Can you give us any specifics about your new product?

Jared: You’re fishing for clues. All I’m going to tell you is that we are making convenience products that mount to the exterior of your camper. If we can help with storage, everyday use, or just fun, that’s what we’re going to do.

TCM: I guess we’re hooked until you make the next announcement. What’s next in your truck camping life?

Jared: We’ve just got back from an eastern Oregon fly fishing trip. Oregon has such a great variety of camping opportunities from high mountain deserts to the ocean to forests. We have lived here most of our lives and we still have more explore in this state. We love truck camping in Oregon.

The only plan set in stone is attending the NATCOA Rally in LaGrande, Oregon. We will have our products on hand for demonstrations. We would love to see you there.

Click here to request a free brochure.