Meet the Texas craftsmen who build classic Capri Campers with the most time-tested and proven materials and techniques known to the truck camper world. Some things are still done best old school.

In just two years, Capri Campers will be 50 years old. For the first 45 years of the company’s existence, Capri Campers focused almost entirely on the rodeo cowboy market. Outside of this predominantly Texas niche, Capri was relatively unknown.

That all changed when father and son team, Pete and Tyson D’Acosta, bought the nearly half-century old manufacturer in 2014 and immediately set-out to reinvigorate the product and company.

With a considerable cash injection, months of long hours, and plenty of sweat equity, Pete, Tyson, and the ten man Capri production team managed to turn this previously stagnant company into a successful force in the truck camper marketplace.

Despite strong sales, Pete and Tyson are far from pulling back on the throttle. As this article goes to press, their building is being expanded, and they are making plans to further grow the company. Suffice it to say that Capri Campers is a company to watch.

Speaking of watching Capri, we were very excited to finally visit and tour the Capri Camper factory this past April. As has been stated many times, there’s no better way to understand a truck camper manufacturer and its products than by visiting their factory, meeting their team, and spending a few days observing them in action. Put on your Stetson hat and cowboy boots. We’re going to Texas.

Capri Campers is located in Bluff Dale, Texas in an 8,400 square foot building. The main office is located at the front and the production floor occupies the rest of the building.

During our visit the plant was preparing for expansion. Specifically, the roof is being widened to shelter Capri’s completed and used inventory from the notorious hail storms in Texas, and a new storage room will allow for additional truck camper production space inside the main plant.

All totaled, the expansion will add 1,680 square feet under roof and 2,800 square feet of covered parking for completed campers.

Capri usually has a half dozen or so freshly completed and used campers on hand. These campers are normally stored on the side of the building, but were in the parking area waiting for the expansion to be completed when we arrived.

Just outside of the main bay door are two horse shoes in the macadam. Now we have seen plenty of lucky horse shoes hung above entry doors for good luck, but never sealed into the pavement. Pete D’Acosta, President of Capri Campers explained, “It’s a Texas thing.”

This photo was taken from a second floor level storage area above the main office and shows about three-quarters of the Capri Campers production floor. The wood shop is in the back just inside the open bay door. Finished campers are on the right, and campers in various stages of production are on the left.

At first it was challenging to understand the production flow at Capri. Most truck camper manufacturers have units at various stages of production moving down a production line with specialized team members at each station.

In contrast, Capri Campers are produced by two man build teams who construct campers from start to completion at a single station. In the above photo you can see two Capri Cowboy models being built by two of these two man build teams.

In addition to the two man teams, the wood shop produces competed sidewalls, rear walls, roofs, and floor frames. There’s also a Foreman who supervises the entire process, but he, too, is hands on building campers.

Framing wood starts in the Capri factory as 2×6 yellow pine lumber. Along the back wall of the building we found a bulk delivery of the yellow pine lumber ready to be processed.

The team member in this photograph is Alvaro Alonso. Alvaro has been with Capri Campers for decades and is the engine behind the Capri wood shop. During production hours, he never stops measuring, cutting, and building Capri Camper frames.

Capri campers are framed in 2×2 and 2×4. To begin the frame construction process, Alvaro checks the 2×6 lumber for quality (clean, straight, and whole) and then cuts the lumber to the required 2×2 and 2×4 dimensions.

Then Alvaro marks the boards for cutting using a series of jigs. The jigs are essentially pre-measured frame beams for each Capri model.

Once the wood is marked with the jig dimensions, Alvaro brings it back to the table saw and cuts it again. This process repeats until all of the required frame members are completed and ready to assemble into a roof, sidewall, interior wall, or floor.

Here we see Alvaro assembling a roof’s frame from the cut lumber. Note the tapered ends of the horizontal beams to allow water runoff.

Completed roofs, sidewalls, interior walls, and floors are stacked throughout the plant.

To further speed production, Capri outsources their interior cabinetry to a local Texas cabinet shop. Once the cabinetry is inspected, it’s placed on the production floor with with the stacked camper frames.

When the build teams begin a new Capri Camper, they pull from the frame stacks and completed cabinetry. This allows Capri truck campers to come together quickly.

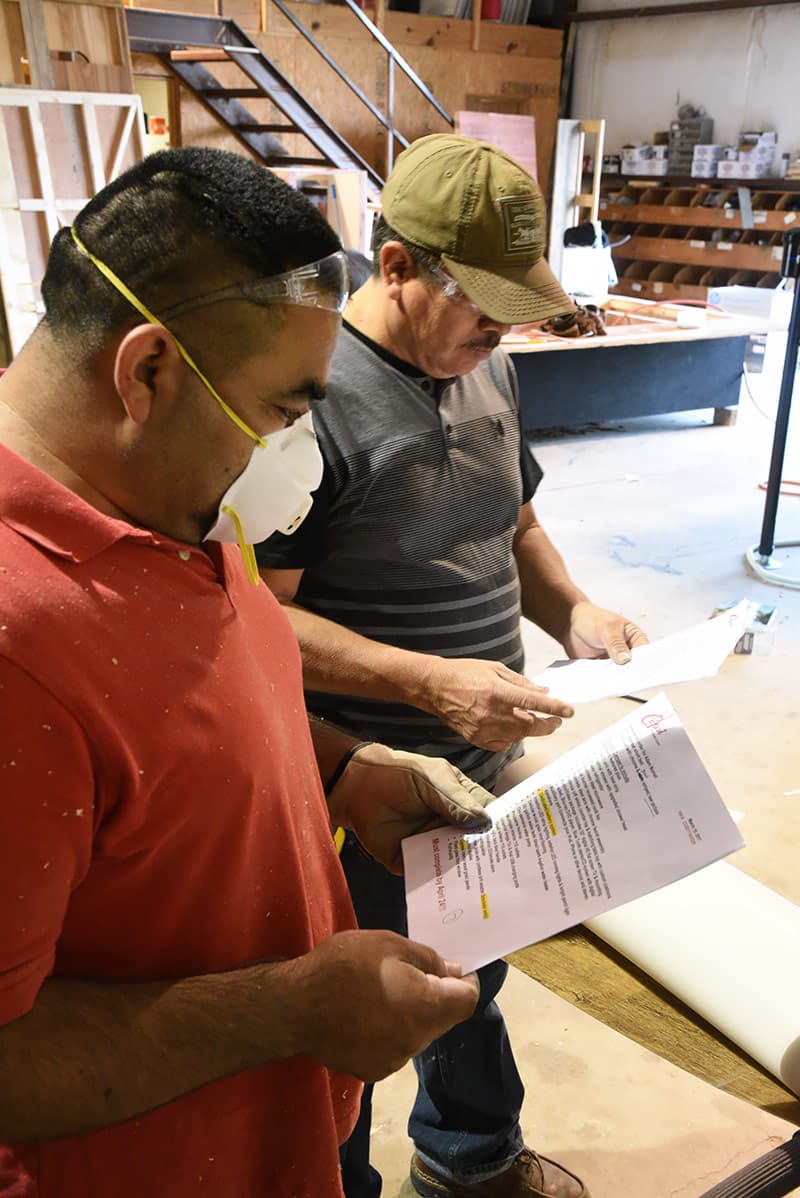

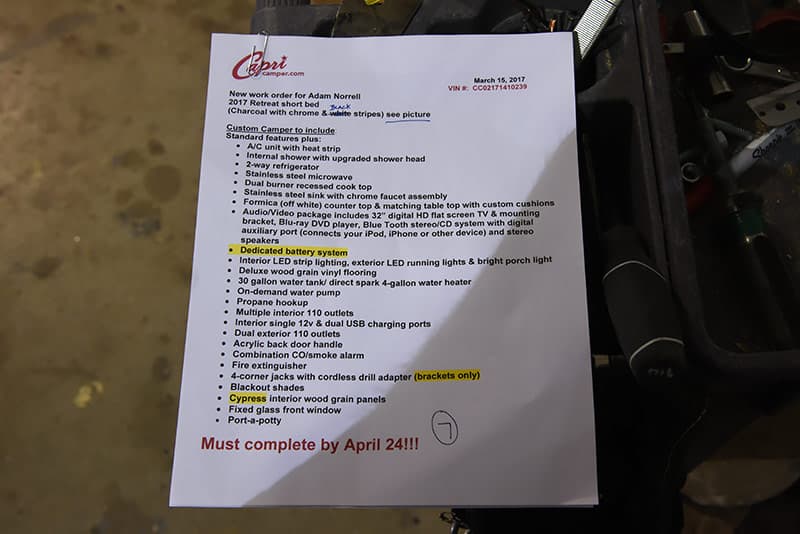

Capri truck campers are sold factory direct. Before beginning a new Capri, the team reviews the customer order sheet. Here we see Francisco Alonso and Zenobio Mata reading their next builds.

The order sheet details the specific model and options for that camper. For example, this camper is a Capri Retreat model, with an air conditioner, and Cypress interior wood paneling (just to name a few customer selected options). Naturally, this is critical information to the build team.

After the framing is completed, the floor is the first part of a Capri Camper that is assembled. After pulling a prepared floor frame, Francisco adds 5/8-inch plywood and routes it to shape.

Then a layer of adhesive is added to the floor. Francisco explained that the adhesive needs to set for about forty-five minutes before the wood grain linoleum flooring can be applied.

While the floor adhesive sets, paneling is added to the interior sidewalls.

When placing their order, Capri Camper customers choose what interior wood paneling they want; Pecan, Ridge Pine, Split Birch, Weathered Cedar, Cypress, Natural Birch, Manhattan Walnut, or aromatic Cedar. In the photo above you can see three of these options ready to be cut and installed.

The selected wood paneling is glued to the camper frame and then fastened with industrial staples. That’s not Dr. Pepper, folks!

When the glue has cured, the sidewalls and windows are routed.

To smooth any potential rough edges from the routing process, the paneling is sanded. Francisco made sure all the routing cuts were smooth.

Getting back to the floor, the adhesive is now ready for the linoleum. First, Francisco carefully placed and unrolled the linoleum onto the floor and adhesive.

Then he routed the linoleum to the shape of the floor.

Finally, Francisco used a roller to push out any air pockets and fully adhered the linoleum to the floor.

With the floor completed, Francisco added the lower front wall and lower sidewalls. The wing walls went on next followed by lifting the camper into its back for underside weather treatment.

Then, Francisco treated the underside of the camper with Rust-Olem Restore 10X Advanced. Described by Rust-Oleum as, “liquid-armor”, Restore 10X Advanced is designed to repel water and create a durable and weather resistant surface.

As the weather treatment cures, Francisco stained the interior cabinetry. The cabinetry in this photo is being stained to match the Weathered Cedar paneling selected by the customer.

For this factory tour, we jumped around to document different build teams at different stages of production. Just down from where Francisco was working, Luis Quirino was working on a Cedar-paneled Capri Retreat.

One of the most popular interior wood paneling choices for Capri Campers is aromatic Cedar. This is exactly the same type of Cedar paneling used in residential closets and cedar chests. Not only does Cedar have that distinct aroma, but Cedar also resists rot and repels many insects – including termites.

Luis is Capri’s in-house Cedar paneling artisan. As we watched, Luis skillfully installed Cedar paneling board-by-board and cut the panels to fit the contours of the Retreat’s interior.

The red Cedar is very distinct and beautiful when applied to the interior of a camper’s wall. Here Luis and his build team partner, Domingo Juarez, lift a rear wall into position.

Even the interior cabinetry gets the Cedar treatment. If you’re into Cedar, or just want the benefits of this remarkable wood, this is a compelling choice.

With the floor, sidewalls, interior walls, and interior cabinetry built prior to camper assembly, a Capri Camper comes together right before your eyes.

In about an hour, Luis and Domingo secured the sidewalls and cabinetry into position. Next thing you know you’re looking at a framed Capri truck camper.

For Capri’s cabover Retreat models, the front nose is secured the same way as the side walls, with nails and industrial staples.

The aluminum skinned front nose of the Capri Retreat cabover is rounded. To make this round front nose possible, Domingo begins by cutting the edge of the nose.

With the sharp front nose cut, Domingo then sands the nose round with a handheld disc sander. In the above photograph you can see the fiberglass insulation used under the front nose cabover. More on this later.

After the disc sander, Domingo further sanded the front nose by hand. Again and again, we watched a Capri team member follow their power sanders with manual hand sanders.

The next team we observed was Zenobio Mata and Jose Luis Avalos who were building a Capri Cowboy.

With the sidewalls, rear wall, and front nose on, Zenobio and Jose carried a prepared Cowboy roof over to their build, carefully put it into position, clamped it down, and then nailed it into place.

Once the roof was nailed down, Jose cut the front nose to create the roof-to-nose bend (see top right) and pulled the roof down to meet the body of the camper. This same technique is used at many truck camper factories.

With the front nose of the roof cut, pulled down, and nailed into position, Jose used a round template to mark a cutting line. This cutting line connects the roof line to the forward wall.

Jose then cut the traced line with a hand jigsaw. This is delicate work that was done with impressive precision. Not bad considering there was some guy over his shoulder taking pictures.

With the front roof line cut and sanded, Jose screwed the nose into the main body of the camper.

To complete the roof frame installation, Jose added the rear port supports.

Once the roof was competed, Zenobio and Jose installed the wiring and electrical components. To begin, a wheeled cart with color-coded wire was brought over and the 12-volt and 110-volt wires are threaded directly from the spools.

As the exterior wiring and electrical elements were installed, Jose moved inside the unit to install the switches and outlets.

Capri Campers uses household electrical switches and 110-volt outlets giving their units something of a domestic feel.

Capri Campers insulates their truck campers with fiberglass insulation. Fiberglass insulation comes in large rolls that are then cut to size and pushed in between the wood frame members of the camper. Much like the rest of how Capri Campers are manufactured, this is an old school approach to RV insulation.

The roof insulation is applied first. Jose brought the insulation to the roof and then unrolled it over the length and front of the unit.

Knife in hand, Jose cut the insulation across the width of the camper and pushed the insulation between the frame members.

While Jose was installing the roof’s insulation, Zenobio was installing the sidewall’s insulation.

Every space between the frame members is filled with fiberglass insulation from back to front.

After Jose and Zenobio completed the insulation, Francisco came over to inspect the customer build sheet and camper. Before the exterior aluminum skin is applied, the build team wants to be sure that nothing has been missed or done incorrectly. An easy fix now will be much more difficult once the aluminum skin is on.

Capri Campers skins their campers in quilted diamond-embossed aluminum and offers an array of aluminum exterior colors and accents including black, blue, chrome, green, maroon, orange, red, silver, white, and yellow.

The embossed aluminum comes in 14-foot sheets coated in a layer of removable plastic film to protect the finish. Here Zenobio removes this plastic film prior to installation.

With the protective film removed, Zenobio measured the aluminum, cut it to the required lengths, and brought it to the camper for installation.

The embossed aluminum is then attached to the wood frame with industrial staples. By folding the top edge of the aluminum, the staples are applied underneath the final aluminum skin and cannot be seen.

Windows are routed out of the installed aluminum skin with a hand router. As you can see, Zenobio often reflects upon his work.

During the process of installing the aluminum, Zenobio cuts the excess material and works the skin into place to create that classic aesthetic Capri is known for.

After the sidewalls are skinned, the aluminum roof skin is applied. The aluminum roof skin has a vertical line pattern and unrolls over the roof much like the fiberglass insulation did.

Here Zenobio nails and staples the aluminum roof skin.

The seams between the roof, sidewalls, rear walls, and base are then sealed with butyl tape, aluminum banding, and Zialoc silicone sealant. Here Lucio Dominguez applies sealant to the roof’s seam.

As wood-framed truck campers, this seal will need to be maintained by the owner. That stated, if the owner maintains these seals, there’s no reason why a wood-framed camper can’t last for decades. Readers often submit photos of their 1960s and 1970s campers to TCM that were built the same way as Capri Campers builds today.

Ignore these camper seals and the sun will eat the original seal application allowing water inside to rot the wood frame. Maintaining camper seals isn’t the whole game for truck camper longevity, but it’s darn close.

Thankfully, the Capri team, including Domingo Juarez pictured above, understood the importance of this task. He was focused!

After completing the seal on a Capri Retreat, Lucio applied the Capri logo on the sides and front nose. It’s always great fun to see the brand decals placed on a brand new truck camper. Why? I have no idea, but I still love it ten years into this gig.

Nearly all interior lighting in a Capri Campers comes from 12-volt 3M LED strip tape. This innovative lighting is literally applied as a tape to nearly any surface and can be cut to the desired length.

Capri installs it along recessed inside lips under cabinetry creating an indirect, well dispersed light inside the unit. After years of typical RV light fixtures, the effect of this bright daylight white-colored LED lighting tape is quite striking.

In the above photo, Josh Moffitt, Capri’s Foreman, applies the 3M LED strip tape behind a forward cabinet lip. This will emit an ambient light in this area.

Capri Campers offers a wide range of options and allows customers to request custom features. For example, the customer that ordered this Capri Retreat requested a rear view camera system that’s viewable on a smartphone via Bluetooth. In this photograph, Lucio and Josh are positioning and testing the camera and system.

As we were wrapping up, Efrain Munoz started to skin a magnificent blue aluminum on another Capri Cowboy. This color was even more beautiful in person than it is in the picture. That’s a camper that’s sure to get attention down the road.

Capri offers a range of fabric options for their customers to choose from. Here you see three sets of locally manufactured cushions ready to be installed into the campers being built during our visit. The quality of these cushions including the fabrics, foam, stitching was truly outstanding.

Back row, left to right: Efrain Munoz, Zenobio Mata, Francisco Alonso, Michael Treadaway (tallest in the very back), Josh Moffitt, Alvaro Alonso, Jose Luis Avalos, Domingo Juarez, and Luis Quirino. Front row, left to right: Tyson D’Acosta, Lucio Dominguez, and Pete D’Acosta.

Before setting out, we gathered the Capri Camper team for a group shot. It’s hard to fully communicate the family culture at Capri Campers, but it’s on full display here.

Like finally putting a face to a name, it’s always fascinating to meet an entire company and absorb their culture and spirit. Yes, our core mission is to learn how a manufacturer builds truck campers, but there’s always at least as much information to be gathered by observing the office and production team over the course of several days.

The first word that comes to mind to describe the Capri production team is craftsmen. Perhaps more than any production-line oriented company, the Capri team is made up of true-craftsmen who literally build individual truck campers from the ground up.

Capri campers start at Capri literally as a pile of yellow pine. From there, the Capri team cuts, shapes, nails, and otherwise sculpts these truck campers into existence. That craftsmanship really struck us.

The second word that comes to mind is camaraderie. There is a palpable sense of shared mission at Capri. While they’re constructing campers in two man build teams, they instantly help one another on different challenges. Funny enough, there’s also a healthy competitive attitude between the teams – all to see who builds the best.

There will be some that see a company building classic truck campers using old school materials and techniques and dismiss Capri Campers as antiquated. That would be a mistake.

While it’s undeniable that Capri’s manufacturing approach is decidedly classic, so is their product line. Remember, this is a company that caters to folks who want an old-school, wood-frame, aluminum skinned truck camper – good old stick and tin. They want something light and simple for a half-ton truck. They love Capri’s retro classic aesthetic and vibe. Quilted aluminum, in a choice of colors? You bet!

If you want aluminum framing, lamination, and slide-outs, Capri isn’t for you. However, if you long for something time-honored, with more than a hint of what truck campers were in their glory days, there may be a Capri in your future.

For more information on Capri Campers, visit their website at CapriCamper.com. Click here for a Capri brochure.